Automatic LCD screen defect detection system

A technology of liquid crystal display and automatic detection, which is applied in the direction of optical testing flaws/defects, measuring electricity, and measuring devices. Low misjudgment rate and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

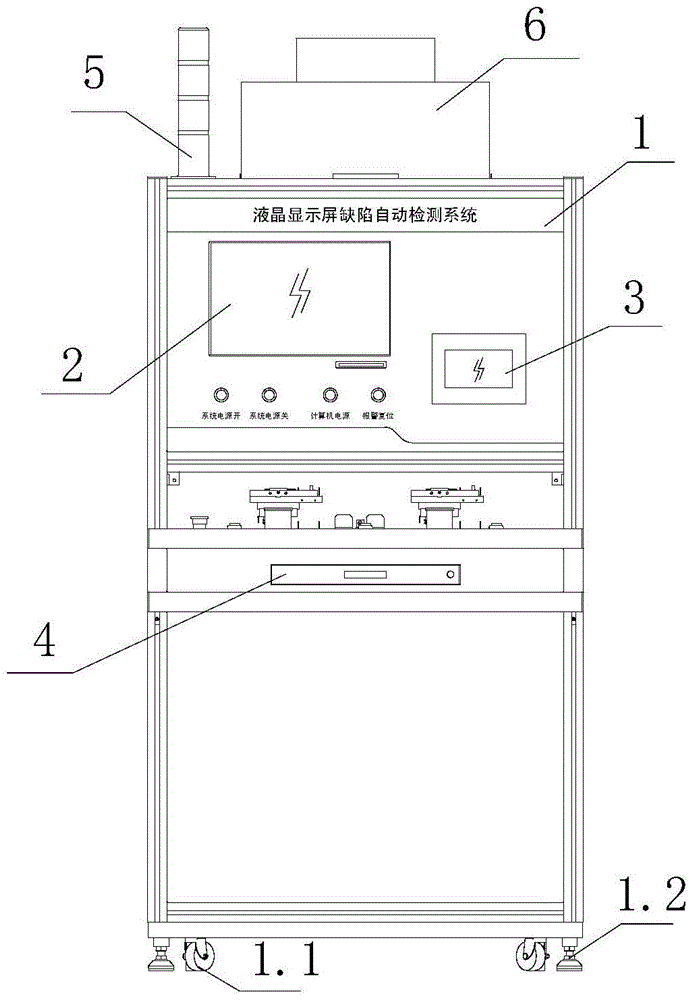

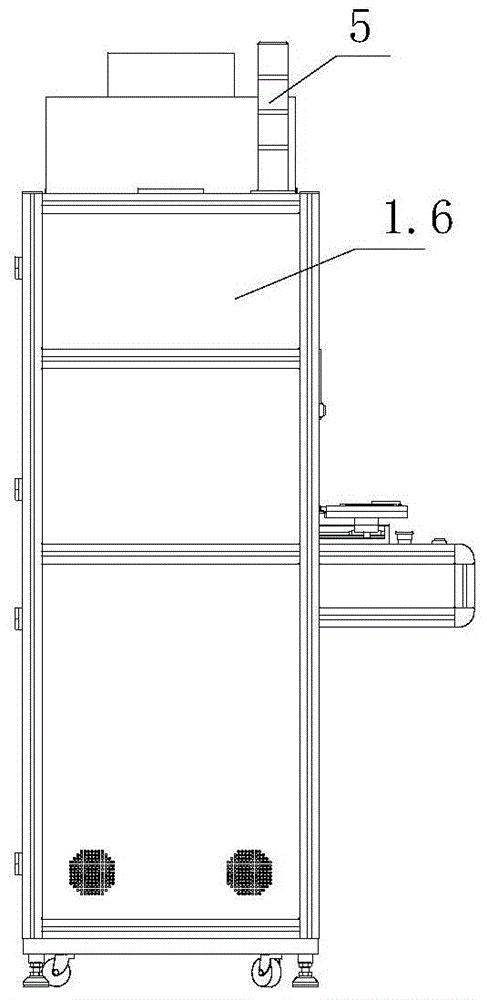

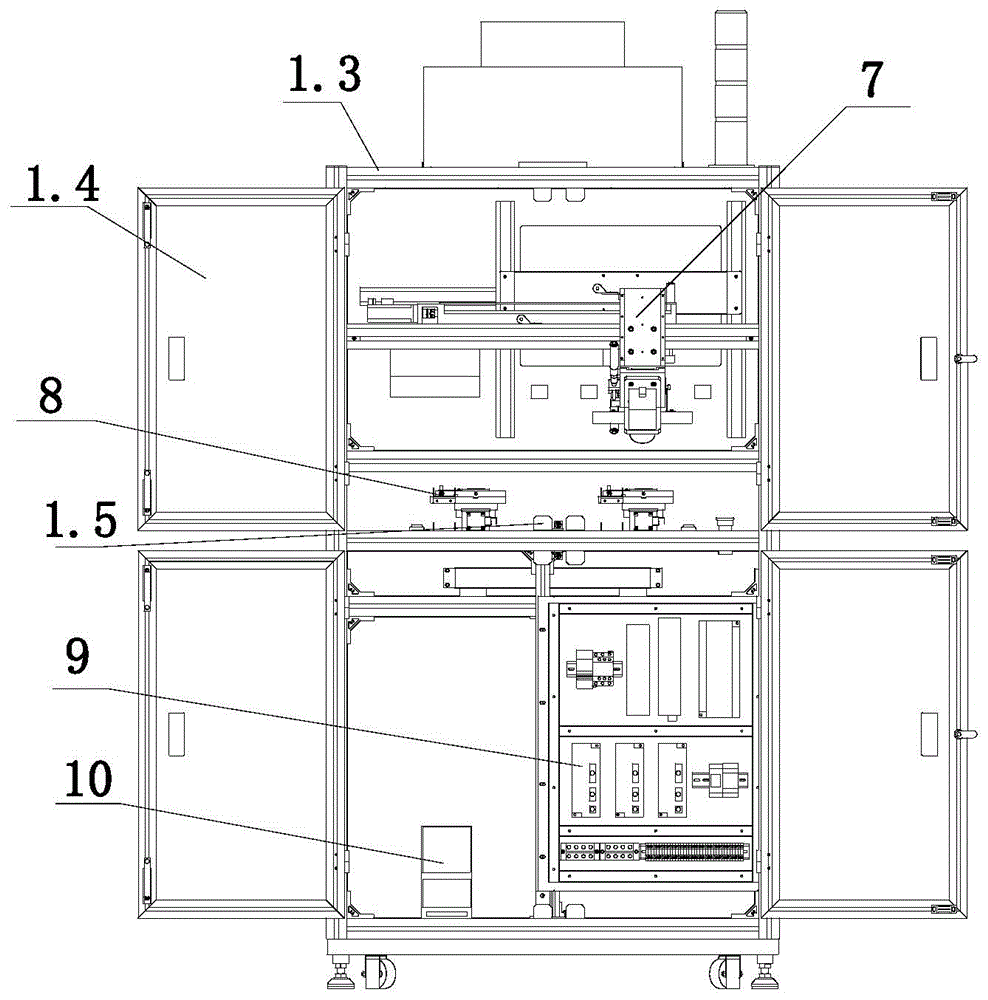

[0035] The invention provides a liquid crystal display defect automatic detection system, such as figure 1 , figure 2 , image 3 As shown, it is mainly composed of two display screen movement assemblies 8, a camera movement assembly 7, an electric control system 9, a computer 10, an alarm 5 and a display 2. Two display screen moving assemblies 8 are arranged in parallel, each display screen moving assembly 8 includes a detection station and an installation station, the installation station is used to install and disassemble the LCD screen under test, and the detection station is used to detect the LCD screen under test . Each display screen moving component can move back and forth between the detection station and the installation station with the screen under test. The camera movement assembly 7 is arranged laterally above the two display screen movement assemblies 8 , and the camera movement assembly 7 can move the camera back and forth between the detection stations of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com