Fuel battery flow field plate

A fuel cell and flow field plate technology, which is applied to fuel cells, fuel cell parts, circuits, etc., can solve the problems of reducing the efficiency of electrochemical reactions, reactants cannot reach the reaction interface, and do not take into account, so as to improve the electrochemical performance. The effect of reaction efficiency, simple structure and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

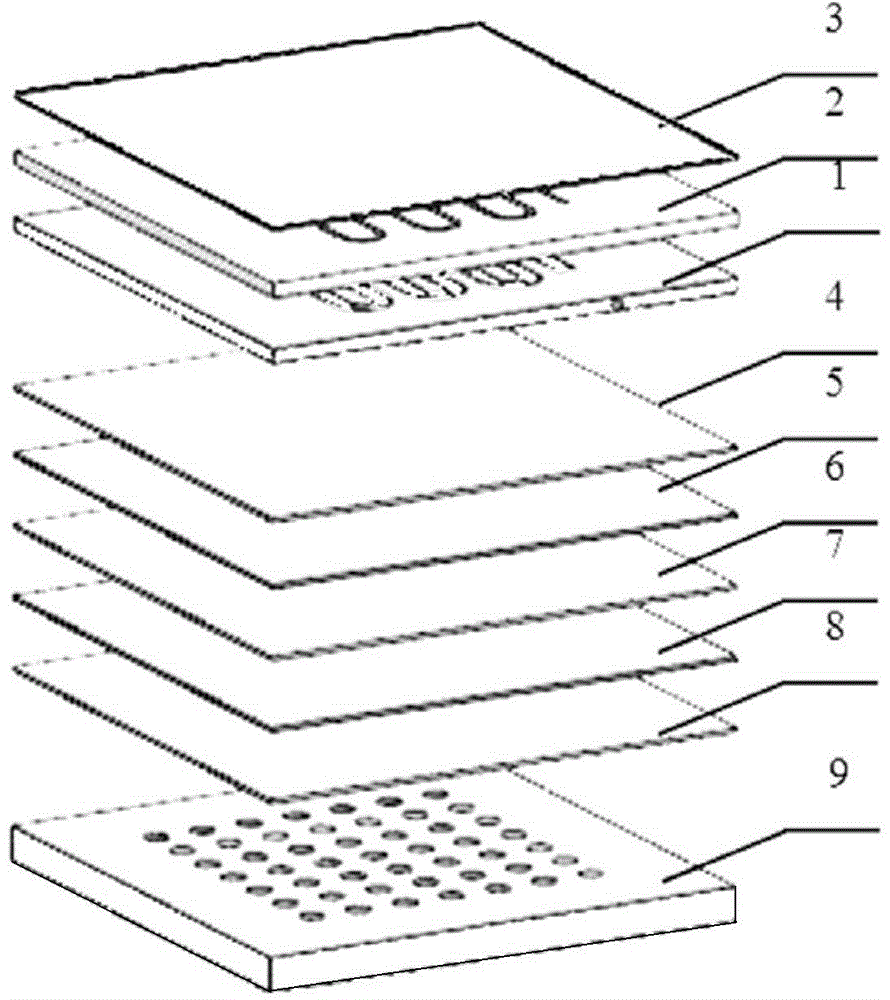

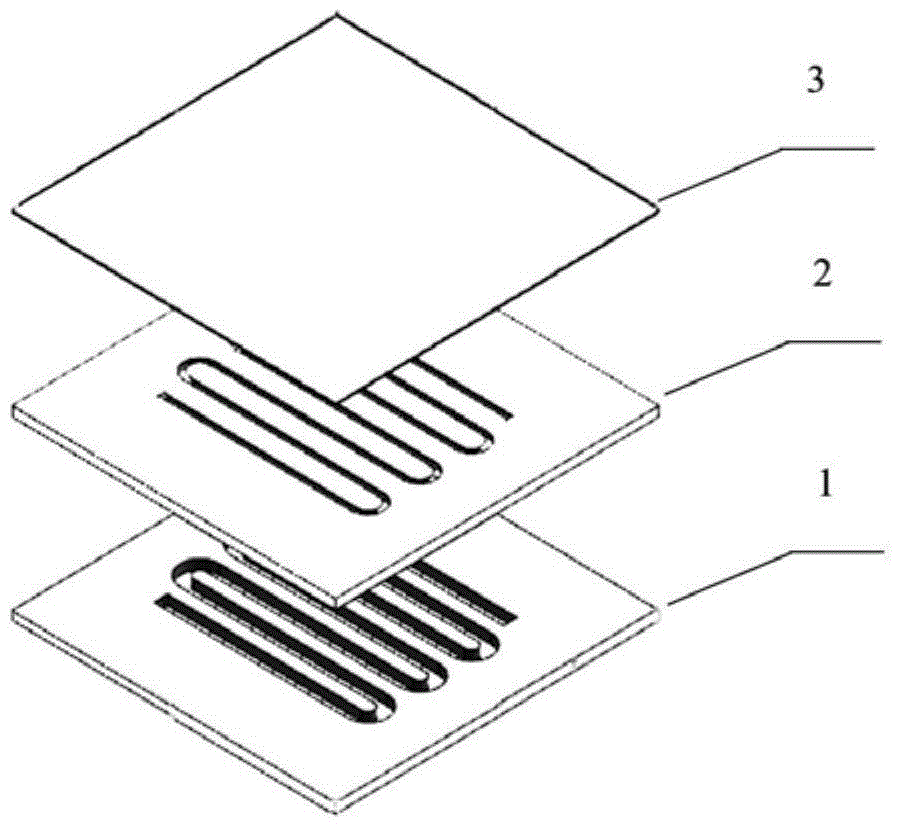

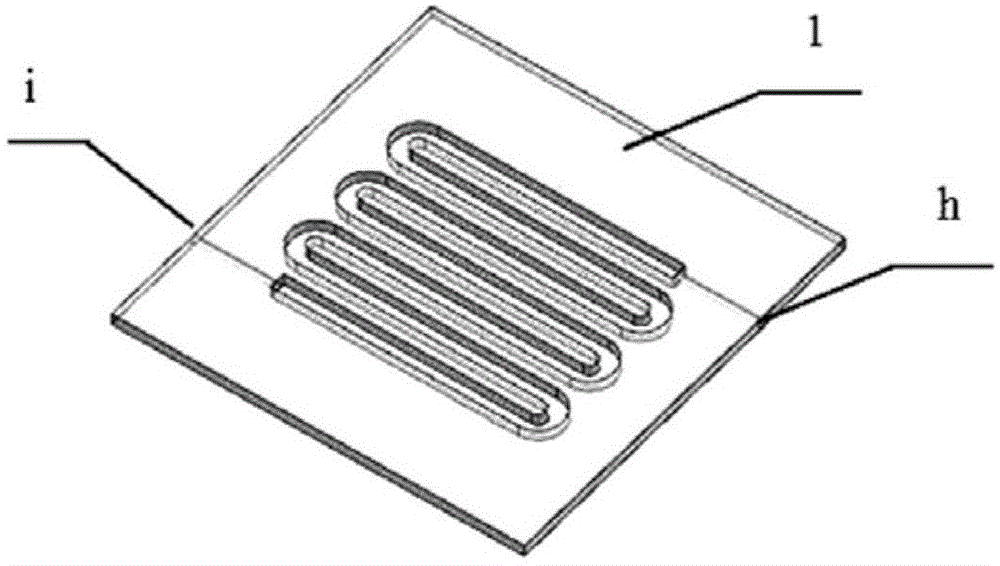

[0019] A fuel cell flow field plate, such as figure 1 As shown, it consists of the bottom flow field plate 1, the middle flow field plate 2 and the top flow field plate 3, and the layers are bonded with sealant; the middle part of the bottom flow field plate 1 and the middle flow field plate 2 is provided with a corresponding Corresponding S-shaped through groove. Such as figure 2 As shown, an inlet h and an outlet i are respectively provided on two opposite sides of the bottom flow field plate 1, and the inlet h and the outlet i communicate with the through groove. Such as image 3 As shown, the cross-sectional shape of the through groove of the bottom flow field plate 1 is rectangular, and the cross-sectional shape of the through groove of the middle layer flow field plate 2 is trapezoidal, and the size of the bottom of the trapezoid is equal to the size of the transverse side of the rectangle; but in practical applications, the through groove The cross-sectional shape i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com