Method for quickly thawing frozen pork

A technology of freezing pork and pork, which is applied in the direction of freezing/cooling to preserve meat/fish, etc., which can solve the problems of insufficient radio frequency understanding and few radio frequency equipment, and achieve the effects of improving enterprise competitiveness, convenient operation, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

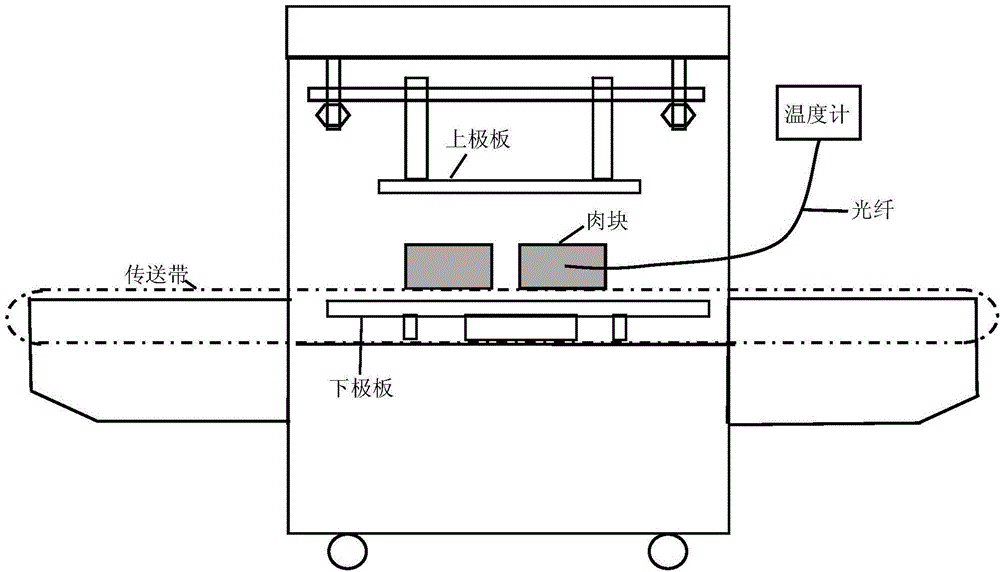

[0025] (1) When thawing for the first time, drill a temperature measuring hole on the meat piece: Take a piece of frozen pork hind leg meat at -18°C with a length of 15cm×15cm×6cm, and drill it from the center of the side of the meat to the center of the meat with an electric drill Drill a hole with a diameter slightly larger than the diameter of the fiber optic thermometer probe, and the depth is to reach the center of the meat piece. Insert the fiber optic thermometer probe into the bottom of the well.

[0026] (2) Select a frequency of 27.12MHz and a plate voltage of 8kV, place the meat between the two plates, set the distance between the plates to 12cm, turn on the power, observe the display of the fiber optic thermometer, stop thawing when the temperature of the center of the meat is -5°C .

[0027] Table 2 shows the results of radio frequency thawing compared with air thawing (temperature 15° C., relative humidity 95%) in this embodiment. It can be seen that the radio ...

Embodiment 2

[0031] (1) When thawing for the first time, drill a temperature measuring hole on the meat piece: Take a piece of frozen pork hind leg meat at -18°C with a length of 15cm x width 15cm x thickness 8cm, and drill it from the center of the side of the meat to the center of the meat with an electric drill Drill a hole with a diameter slightly larger than the diameter of the fiber optic thermometer probe, and the depth is to reach the center of the meat piece. Insert the fiber optic thermometer probe into the bottom of the well.

[0032] (2) Select the radio frequency thawing equipment with a frequency of 27.12MHz and a plate voltage of 7.2kV, place the meat between the two plates, set the distance between the plates to 15cm, turn on the power, and observe the display of the optical fiber thermometer. When the temperature of the center of the meat is - Stop thawing at 2°C.

[0033] The results of radio frequency thawing and microwave thawing (frequency 2450MHz, input power 1300W, ...

Embodiment 3

[0038] (1) When thawing for the first time, drill a temperature measuring hole on the meat piece: Take a piece of frozen pork hind leg meat at -18°C with a length of 15cm x width 15cm x thickness 12cm, and use an electric drill to drill the meat piece from the center of the side of the meat piece to the center of the meat piece Drill a hole with a diameter slightly larger than the diameter of the fiber optic thermometer probe, and the depth is to reach the center of the meat piece. Insert the fiber optic thermometer probe into the bottom of the well.

[0039] (2) Select a radio frequency thawing device with a frequency of 27.12MHz and a plate voltage of 7.2kV, place the meat between the two plates, set the distance between the plates to 20cm, turn on the power, and observe the display of the optical fiber thermometer. When the temperature of the center of the meat is - Stop thawing at 2°C.

[0040] The results of radio frequency thawing in this embodiment are listed in Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com