Negative pressure drying device

A drying device and negative pressure technology, which is applied in the field of vacuum drying equipment, can solve problems such as indoor environmental impact, waste of heat energy, and high power consumption, and achieve the effect of accelerating drying efficiency and increasing water evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The implementation of the present invention will be described below in conjunction with the accompanying drawings.

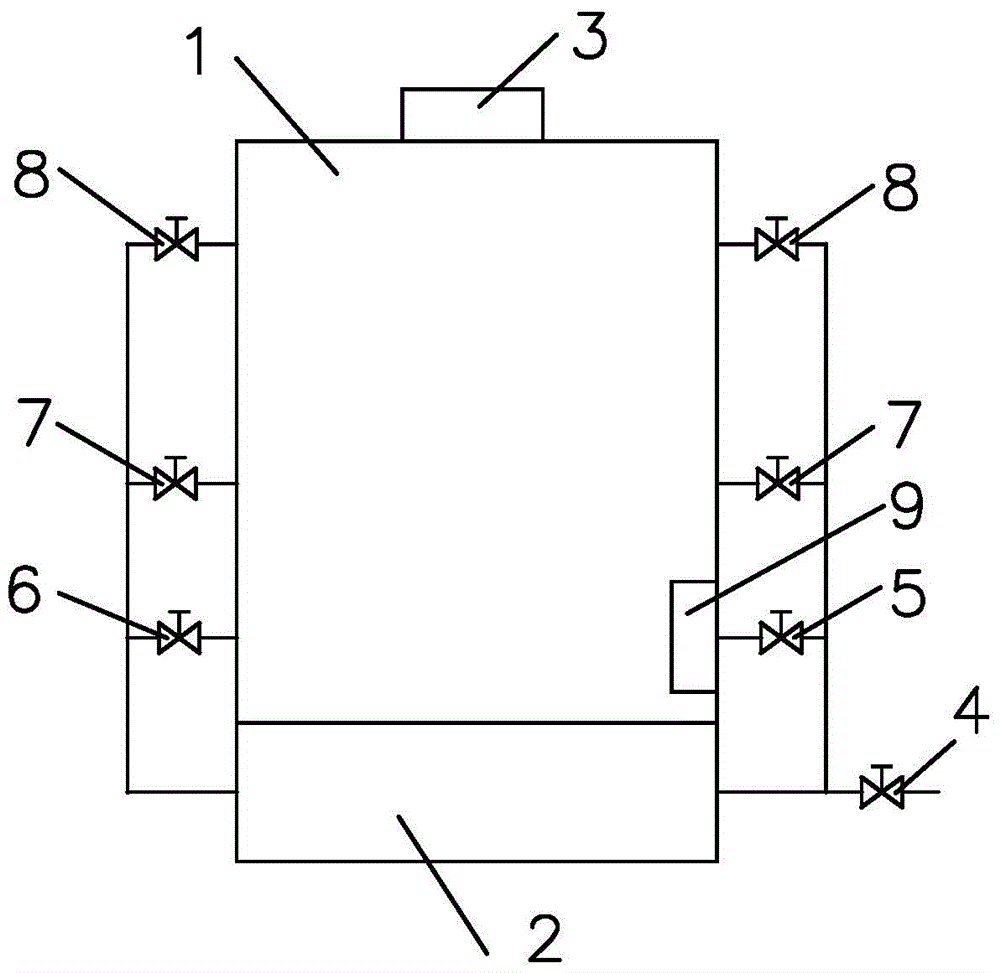

[0014] like figure 1 As shown, a box body 1 is included, and a mesh support frame is installed in the box body 1 . The lower part of the box body 1 is provided with a negative pressure pump 2, the upper part of the box body 1 is equipped with a controller 3, and the negative pressure pump 2 is connected to the controller 3. Corresponding convection holes are set in the box body 1, and the convection holes in the same group are respectively connected to the inlet and outlet ends of the negative pressure pump 2 through valves 7 and 8 to form an annular circulation channel. The tank 1 and the intake end of the negative pressure pump 2 are communicated through a valve 6 ; The air outlet of the negative pressure pump 2 is connected to the heater 9 arranged in the box body 1 through the valve 5 , the heater 9 controller 3 is connected to the power supply, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com