a fine crusher

A kind of fine crushing machine, fine technology, applied in the direction of mechanical equipment, engine components, engine sealing, etc., can solve the problems of reduced crushing efficiency, uneven discharge particle size, weak crushing ability, etc., achieve high crushing and screening efficiency, and prevent dust Good dispersion and good uniformity of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

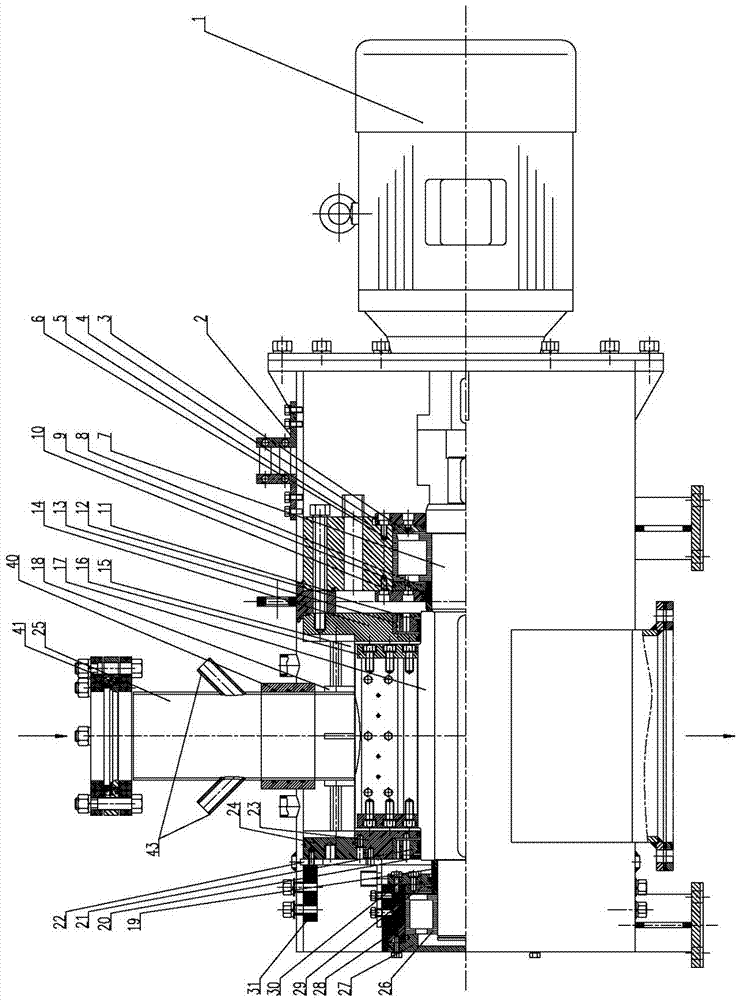

[0040] Such as Figure 1 to Figure 7 As shown, this fine fine crusher is composed of two parts: the frequency conversion motor and the main body of the fine fine crusher.

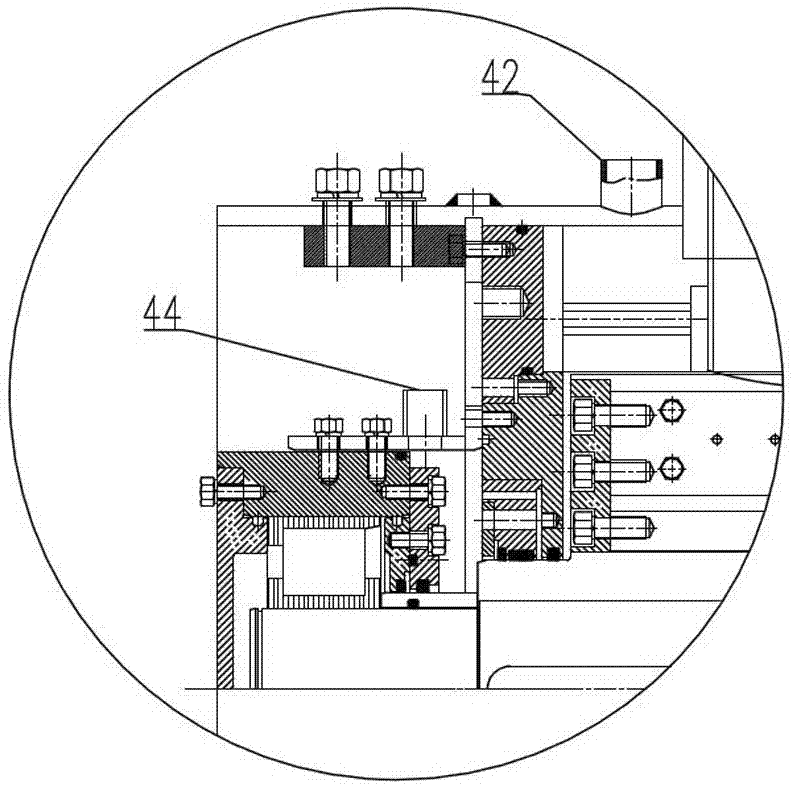

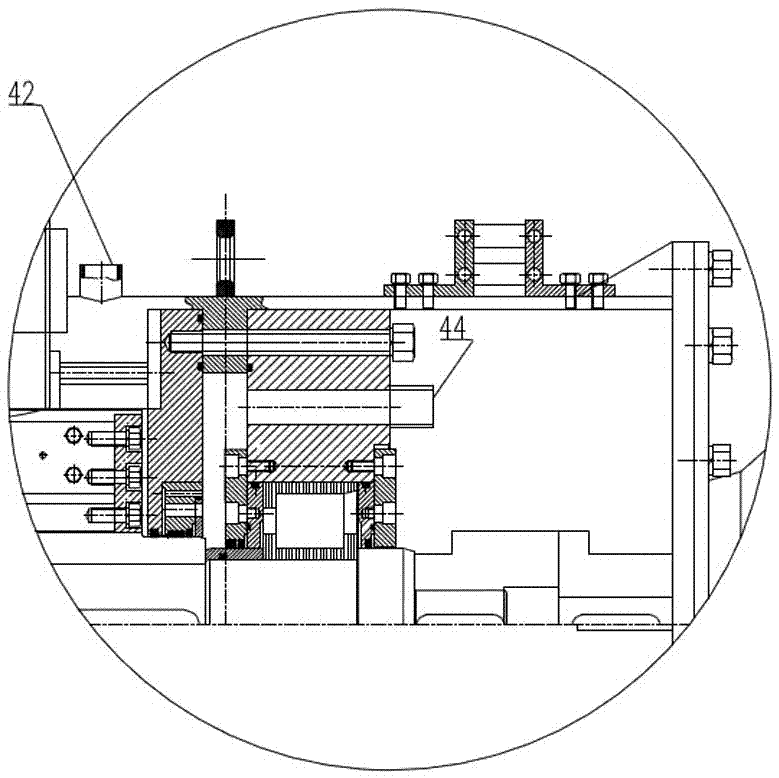

[0041] The main body of the fine crusher is a horizontal structure, which includes four parts from top to bottom: the iron remover 41, the feeding conduit 25, the cylinder of the fine crusher, the discharge port, and the supporting stand; The flange is connected to the upper end of the incoming material pipeline or equipment, and the discharge port is connected to the lower end of the pipeline or equipment through a rectangular flange; the outside of the fine crusher cylinder is a cylindrical casing, and the inside includes the front end bearing seat and sealing assembly, crushing machine in sequence along the axial direction. There are four parts: screen integrated assembly, rear end bearing housing and sealing assembly, and coupling.

[0042] The crushing and screening integrated assembly includes four p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com