Intelligent and automatic separate inspecting and tube arranging equipment

A kind of equipment and automatic technology, applied in sorting and other directions, can solve the problems of disorganized conveyor belt, occupying working hours, etc., and achieve the effect of ingenious structure design, increase energy consumption, and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

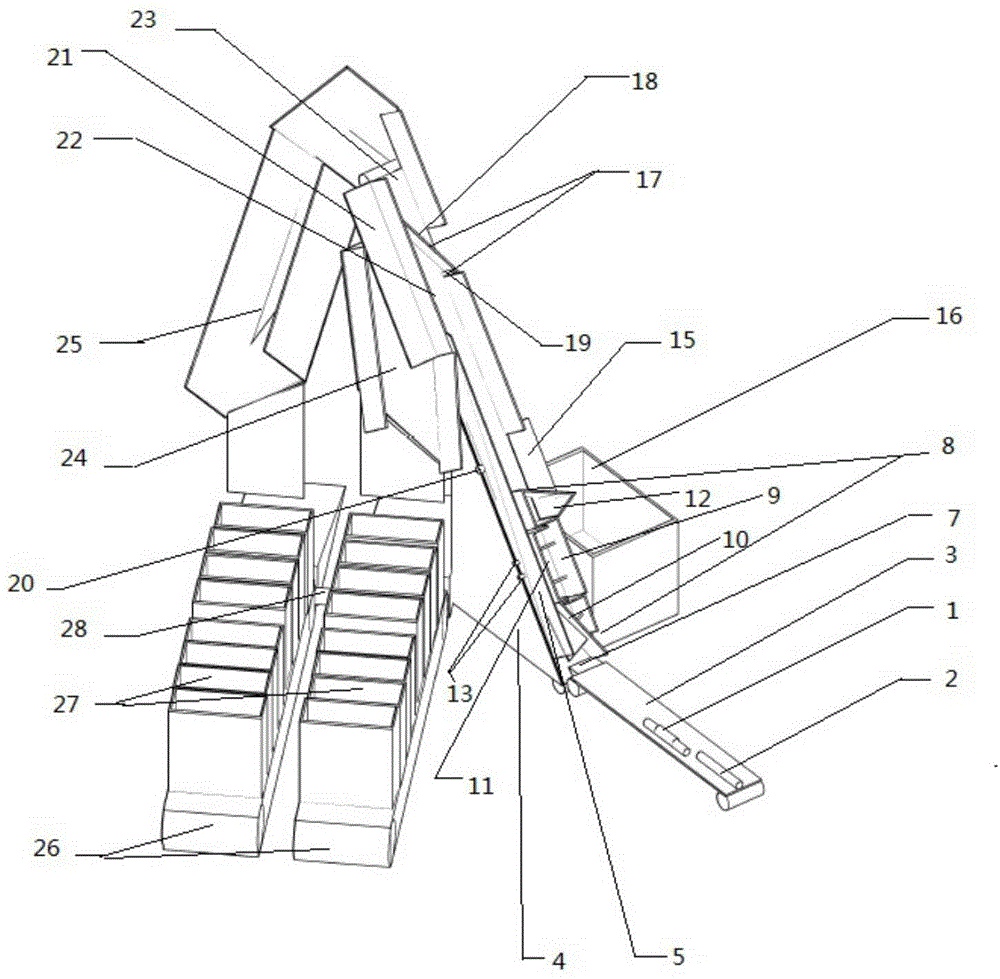

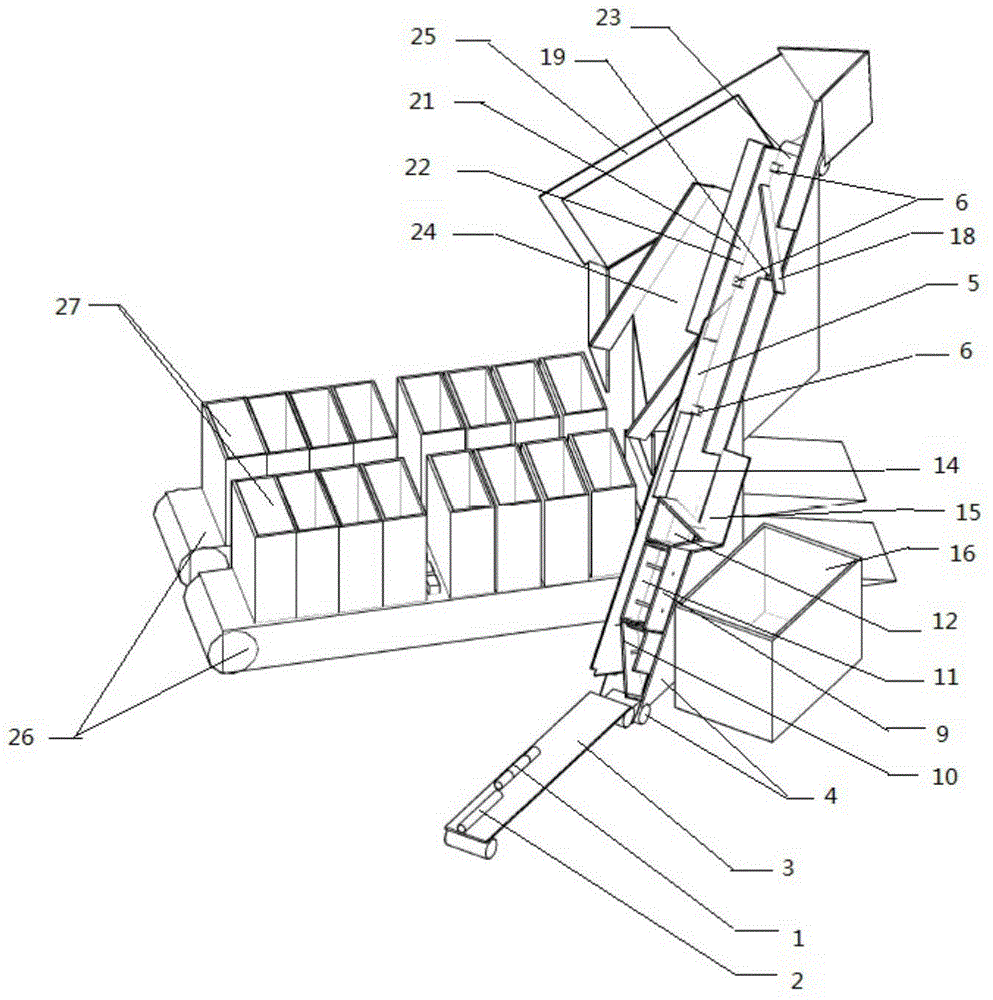

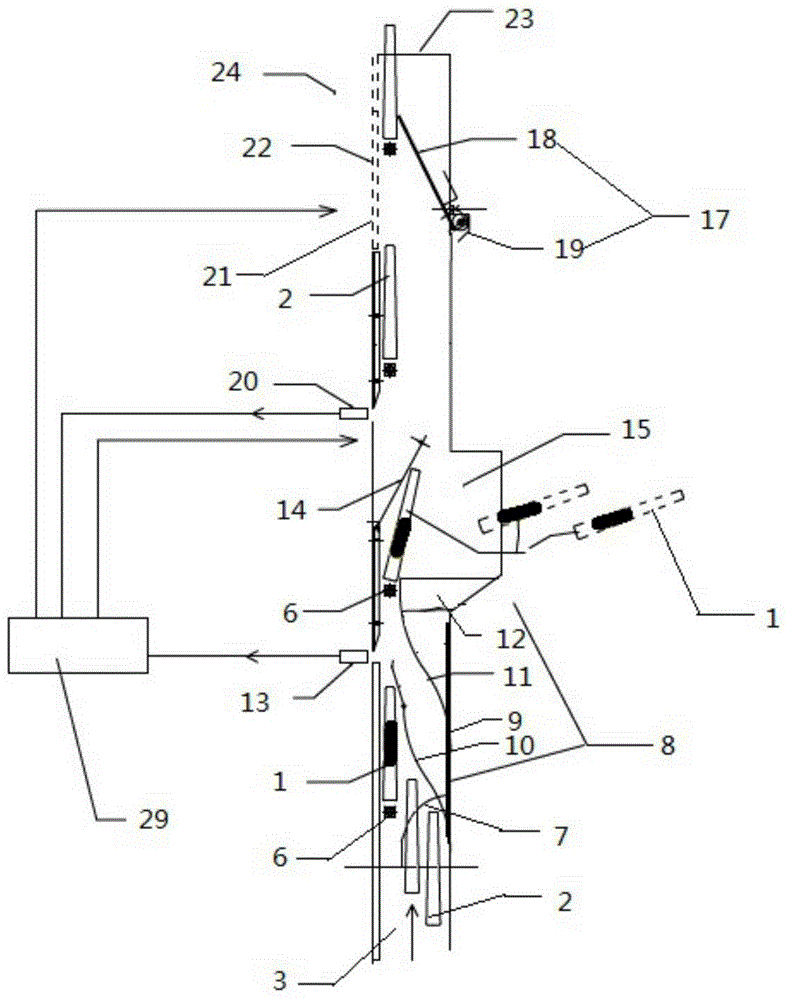

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] Such as figure 1 , 2 , 3, 4, 5, and 6, an intelligent automatic sorting and pipe swinging device of the present invention includes a horizontal conveying device 3, an inclined conveying device 4, a baffle plate 5, a pipe-taking block 6, and a control block 7. Movable inlet tube limiting plate body 8, yarn picking sensor 13, yarn beating handle plate 14, yarn outlet handle mouth 15, yarn storage handle box 16, yarn beating tube plate body 17, tube sensor 20, tube baffle plate 21, A tube outlet 22, a second tube outlet 23, a first tube outlet channel 24, a second tube outlet channel 25, a mobile transmission device 25, a yarn storage tube box 27, a full tube sensor 28, the front end of the horizontal transmission device 3 An inclined conveying device 4 is connected, and baffles 5 are arranged on both sides of the inclined conveying device 4, and a plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com