Adjustable self-centering tool false shaft

A tooling dummy shaft and self-centering technology, which is applied to workpiece clamping devices, metal processing, manufacturing tools, etc., can solve the problems of low utilization rate and increased production cost, and achieve high utilization rate, high positioning accuracy and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following structural drawings describe in detail the adjustable self-centering frock dummy shaft of the present invention.

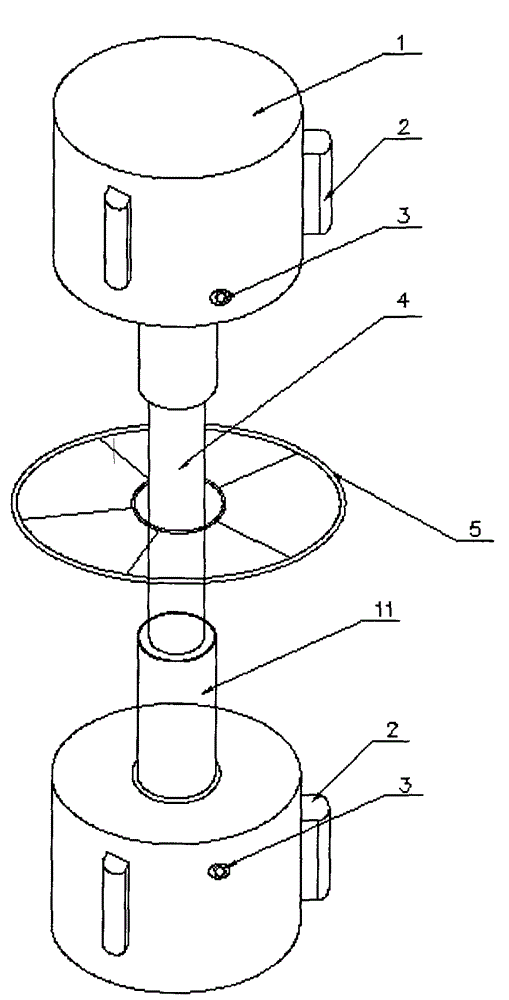

[0014] combine Figures 1 to 3 It can be seen that an adjustable self-centering tooling false shaft includes a connecting rod 4, a rotating handle 5, and a cylindrical support 1. The rotating handle 5 is arranged in the middle of the connecting rod 4, and the cylindrical support 1 is arranged symmetrically. at both ends of connecting rod 4.

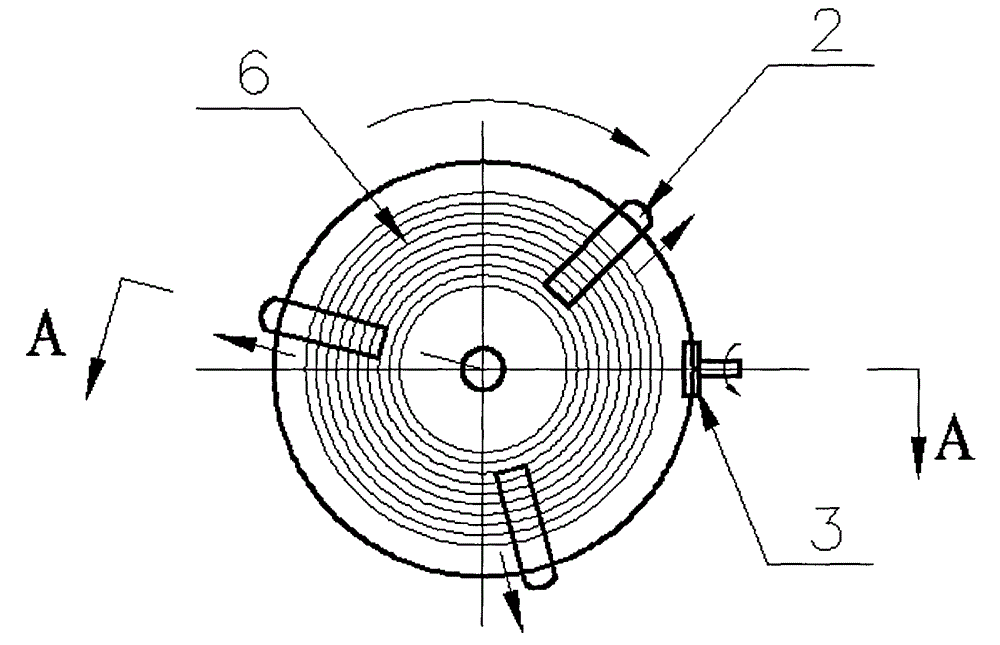

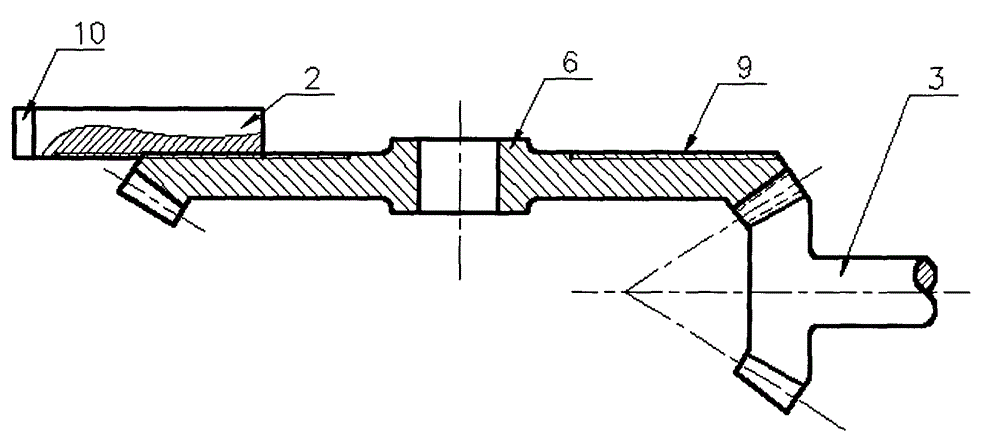

[0015] The cylindrical support 1 includes three strip braces 2 , and the strip braces 2 are evenly distributed at 120 degrees on the side wall of the cylindrical support 1 . The supporting surface 10 of the strut 2 is a cylindrical surface.

[0016] Described cylinder bearing 1 also comprises adjusting nut 3, rotating disk 6, and described rotating disk 6 is arranged on the inside of cylinder bearing 1, and the back side of described rotating disk 6 is provided with plane threaded knot 9, and the back s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com