Production method of non-surplus-slurry and non-autoclaved prestressed concrete pipe pile

A technology for concrete pipe piles and production methods, which is applied in the direction of reinforcement molding, ceramic molding machines, manufacturing tools, etc., and can solve problems such as high cost and difficulty in popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of production method of free autoclaved prestressed concrete pipe pile without residual slurry, comprises the steps:

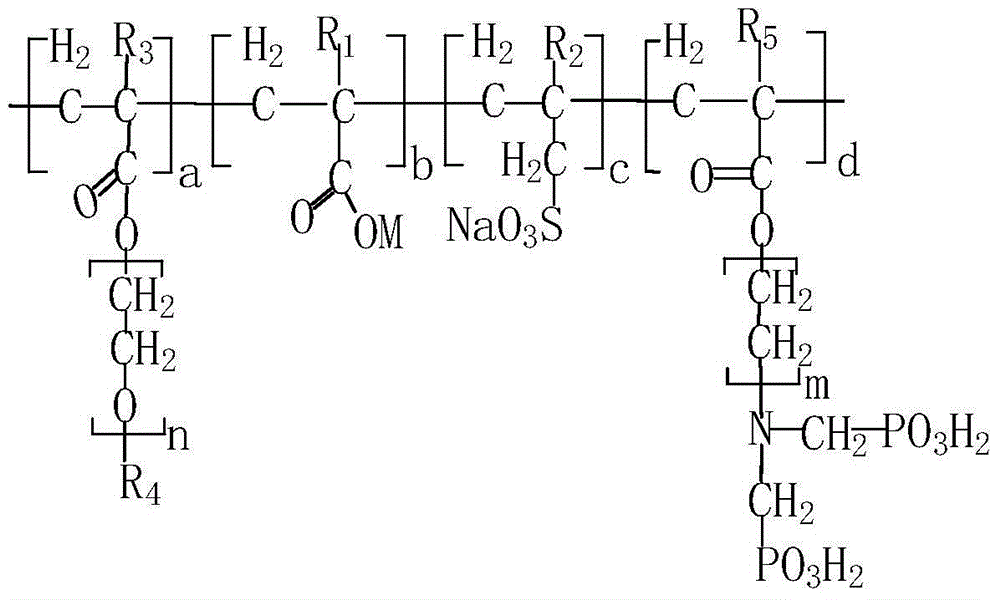

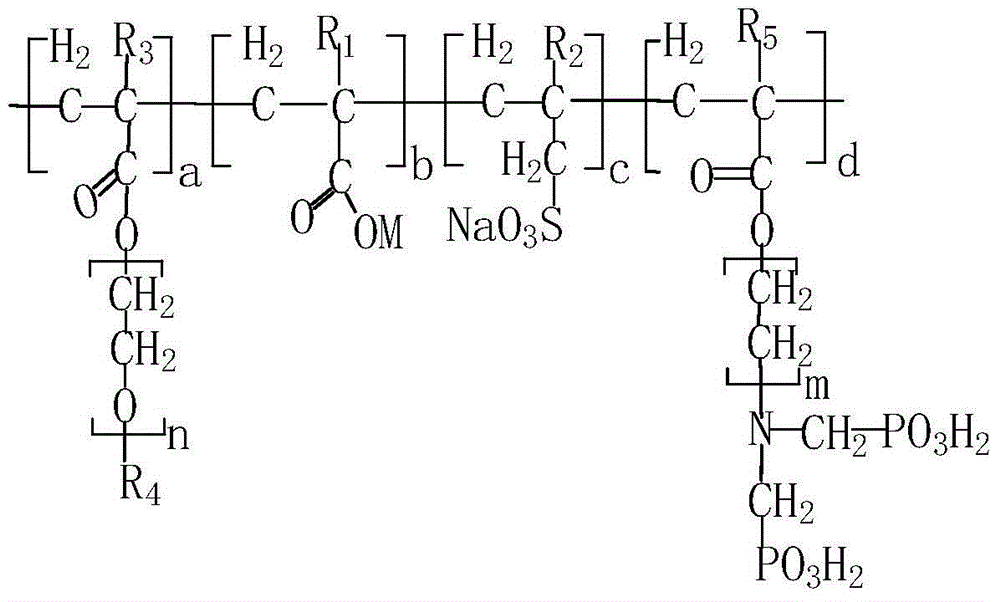

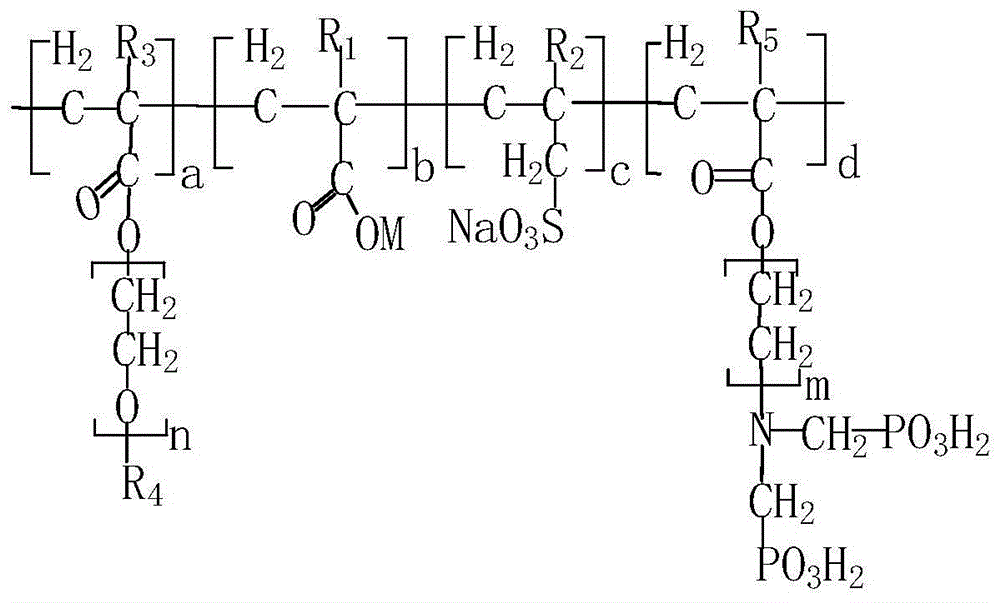

[0019] Step 1. Preparation of raw materials, in parts by weight, the raw materials are composed of the following components: cement 390, fly ash 100, sand 790, water 133, stone 1142, new polycarboxylate superplasticizer 8, activator 5 ;

[0020] Step 2, cloth, mold clamping and tension processing;

[0021] Step 3, performing low-speed, low-medium-speed, medium-speed and high-speed centrifugation steps successively;

[0022] In the low-speed centrifugation step, the rotating speed is 75r / min, and the time is 5min. The rotating speed of the low-medium speed centrifugation is 139r / min, and the time is 1.5min. 545r / min, the time is 2min;

[0023] Step 4, steaming at room temperature, the steaming at room temperature includes three stages of heating, constant temperature and cooling, the time is respectively 1.2h in the heating stage; 3h in the con...

Embodiment 2

[0031] A kind of production method of free autoclaved prestressed concrete pipe pile without residual slurry, comprises the steps:

[0032] Step 1. Preparation of raw materials, in parts by weight, the raw materials are composed of the following components: cement 404, fly ash 112, sand 739, water 140, stone 1128, new polycarboxylate superplasticizer 13, activator 15 ;

[0033] Step 2, cloth, mold clamping and tension processing;

[0034] Step 3, performing low-speed, low-medium-speed, medium-speed and high-speed centrifugation steps successively;

[0035] In the low-speed centrifugation step, the rotating speed is 70r / min, and the time is 5min. The rotating speed of the low-medium speed centrifugation is 125r / min, and the time is 1.8min. It is 459r / min, and the time is 1.9min;

[0036] Step 4, steaming at room temperature, the steaming at room temperature includes three stages of heating, constant temperature and cooling, the time is respectively 1.3h in the heating stage;...

Embodiment 3

[0044] A kind of production method of free autoclaved prestressed concrete pipe pile without residual slurry, comprises the steps:

[0045] Step 1. Preparation of raw materials, in parts by weight, the raw materials are composed of the following components: cement 417, fly ash 115, sand 670, water 140, stone 1150, new polycarboxylate superplasticizer 14, activator 19 ;

[0046] Step 2, cloth, mold clamping and tension processing;

[0047] Step 3, performing low-speed, low-medium-speed, medium-speed and high-speed centrifugation steps successively;

[0048] In the low-speed centrifugation step, the rotating speed is 73r / min, and the time is 4min. The rotating speed of the low-medium speed centrifugation is 136r / min, and the time is 2.4min. The rotating speed of the medium-speed centrifugation is set to 230r / min. It is 533r / min, and the time is 1.2min;

[0049] Step 4, steaming at room temperature, the steaming at room temperature includes three stages of heating, constant temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com