Punching stick manufacturing machine

A technology for stamping rod making machine and rod making machine, which is applied in the direction of stamping machine, press machine, material forming press, etc., can solve the problems of difficult maintenance, short service life, affecting the quality and appearance of the salary rod, and achieves increased energy. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

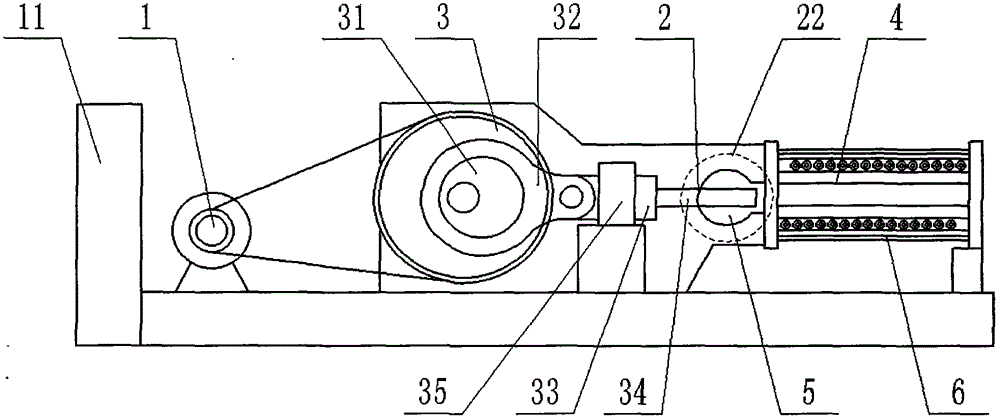

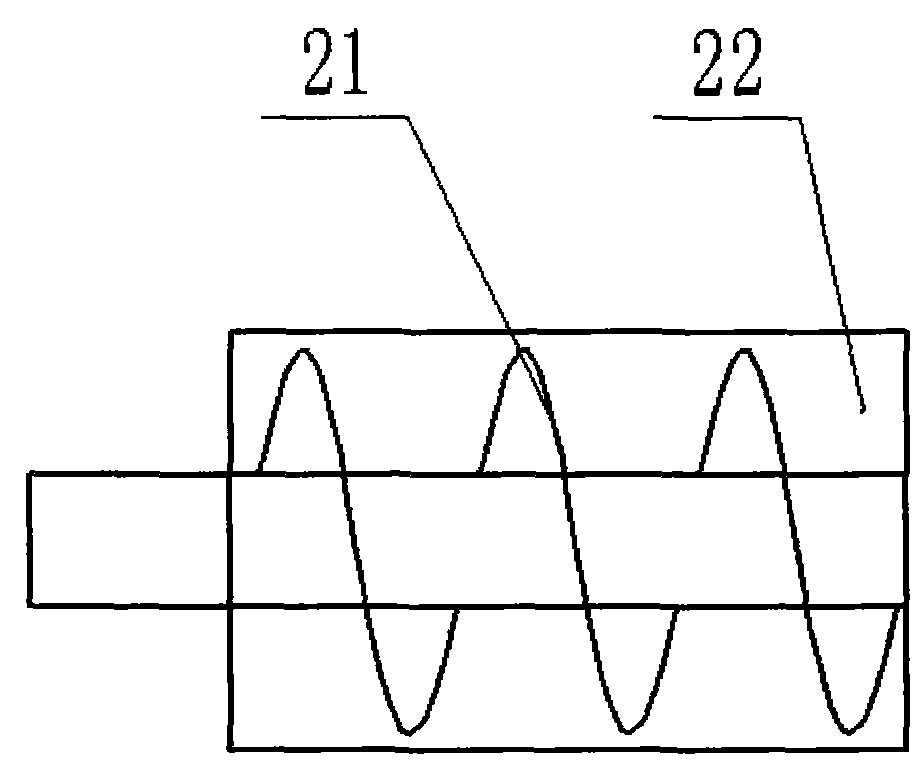

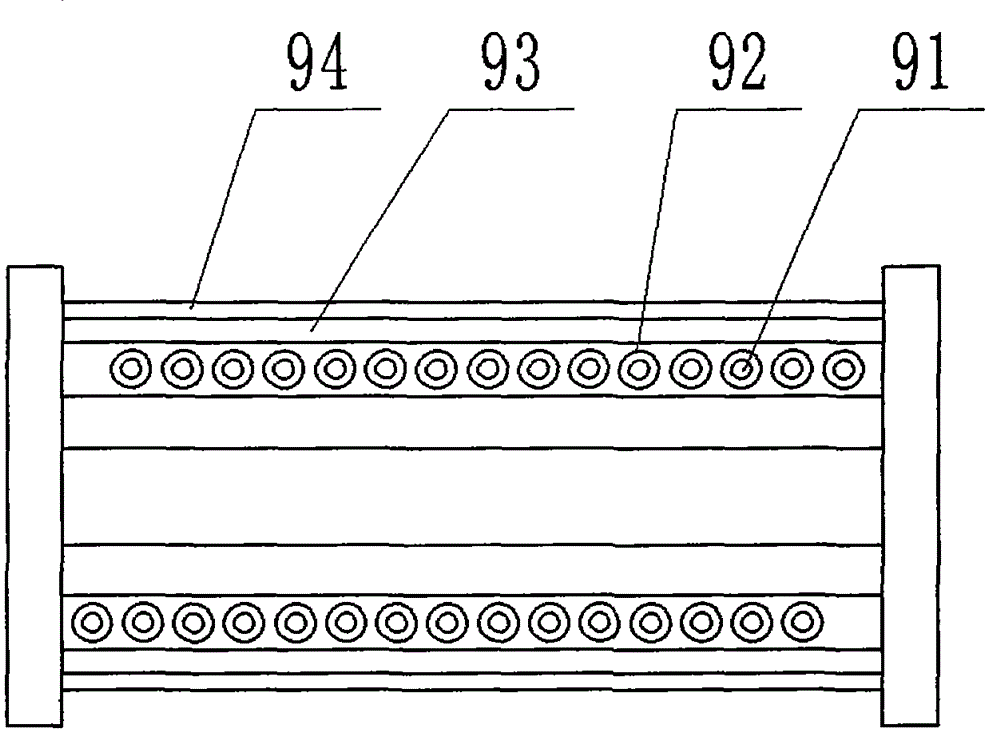

[0017] see Figure 1-3 , a stamping bar machine, including a power unit 1, an extruding device 2 and a molding die 4 installed on a base and connected in sequence, the extruding device 2 includes a pre-compression screw 21 and a stamping extrusion mechanism 3; pre-compression The tightening screw 21 is connected to the side of the material chamber 5, and the molding die 4 is fixedly connected to the rear end of the material chamber 5; the stamping extrusion mechanism 3 is aligned with the molding die 4 through the material chamber 5; the pre-compression screw 21 is located in the pre-compression silo 22, The pre-compression silo 22 is located on the side of the material chamber 5 and communicates with it; the stamping extrusion mechanism 3 includes an eccentric wheel 31 driven by the power unit 1, a pull rod 32 whose beginning end is sleeved on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com