Load-bearing type four-bar linkage automatic deviation correction device

An automatic deviation correction device and a four-link technology, applied in the direction of transportation and packaging, conveyor objects, conveyors, etc., can solve problems such as insufficient belt strength, insufficient sensitivity of the deviation correction effect, etc., to achieve deviation correction, labor saving, Prevents the phenomenon of belt curling and prevents water and coal from entering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

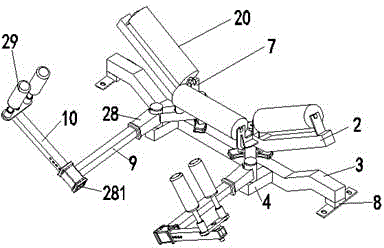

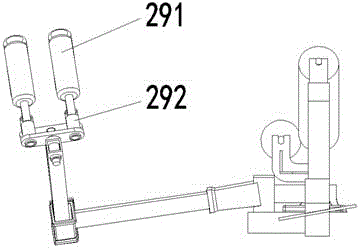

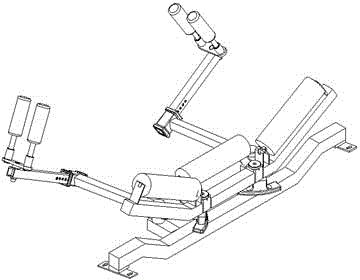

[0031] The load-bearing four-link automatic deviation correction device includes a runway mechanism. The runway mechanism includes a crossbeam and a rotating assembly. The crossbeam includes an idler beam 2 and a load-bearing beam 3. 3 are connected by a pair of rotating assemblies I1; a pair of forward-extending square tubes 4 are provided at both ends of the load-bearing beam 3, and rotating assemblies II6 are arranged on the forward-extending square tubes 4; rotating assemblies II6 and rotating assemblies I1 are connected by connecting pieces 5 connect.

[0032] Three pairs of brackets 7 are welded on the roller beam 2, and three rollers 20 are arranged between the three pairs of brackets; the inclined bottom plate 8 is arranged at the bottom of both ends of the load-bearing beam 3, which is a connecting part for connecting with the conveyor frame Fixed connection;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com