Large liquid measure constant pressure displacement indoor physical simulation experiment device

A technology of physical simulation and experimental device, which is applied in the fields of production fluids, wellbore/well components, earthwork drilling, etc. It can solve the problems of heavy workload, prone to vibration, affecting the progress of experiments, etc., achieving a high degree of automation and improving experimental Progress, the effect of saving a lot of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

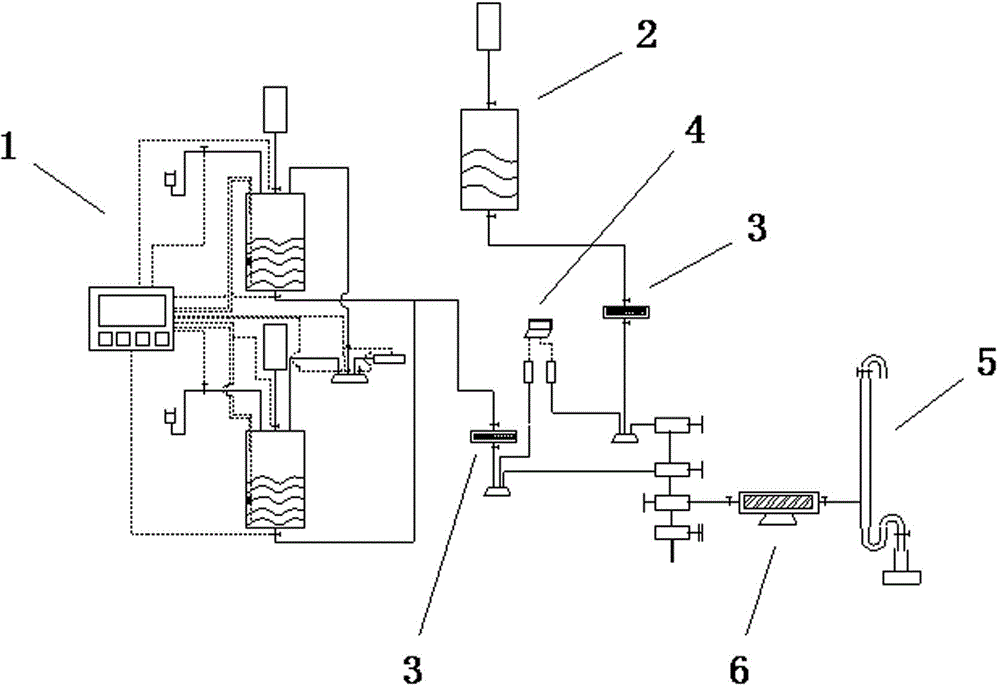

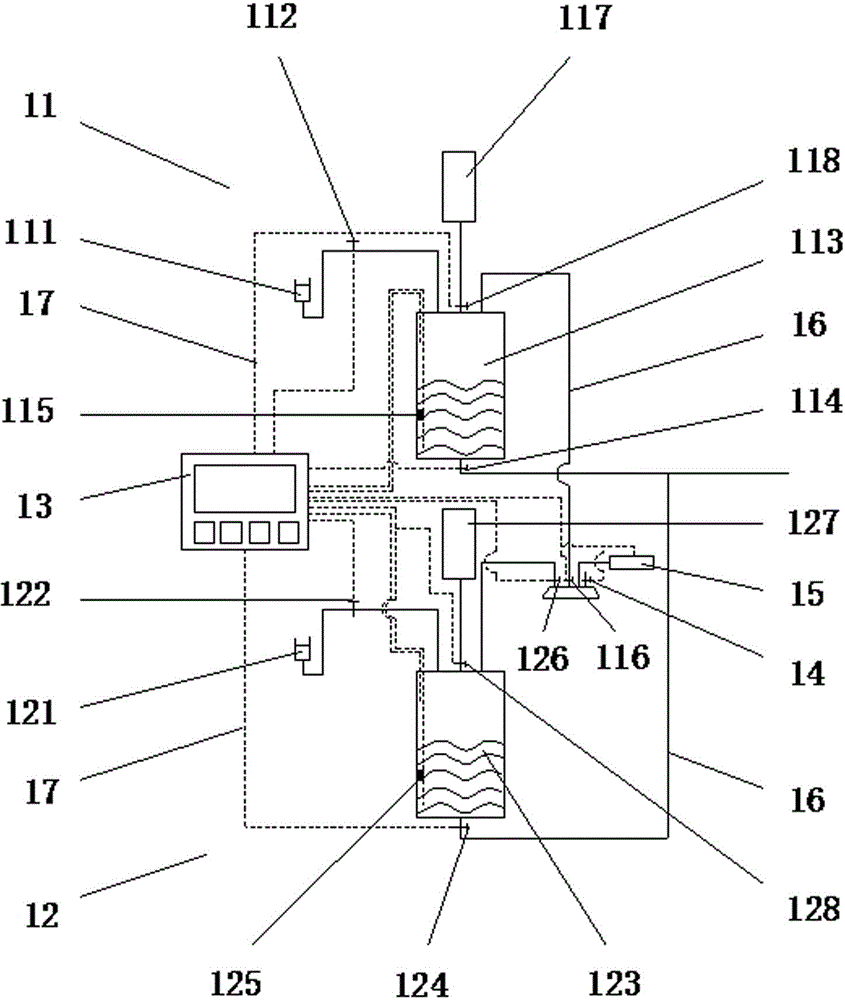

[0100] Such as figure 1 As shown, according to an embodiment of the large liquid volume constant pressure displacement indoor physical simulation experiment device of the present invention, it includes an automatic water adding device 1, a refueling device 2, an impurity removal device 3, a pressure acquisition device 4, an oil-water metering device 5 and The core holding device 6, the automatic water adding device 1 includes the automatic water adding device I11 and the automatic water adding device II12, the impurity removing device 3 includes the impurity removing device I31 and the impurity removing device II32, the automatic water adding device I11 and the automatic water adding device The devices II12 are all connected to the impurity removal device I31, and the fueling device 2 is connected to the impurity removal device II32.

[0101] This embodiment adopts two sets of automatic water adding devices, which can provide sufficient water source for the large-volume consta...

Embodiment 2

[0153] Such as Figure 7 As shown, according to another embodiment of the large liquid volume constant pressure displacement indoor physical simulation experiment device of the present invention, its structure, connection relationship between various components, working principle, experimental method and beneficial effect, etc. are all the same as those of Embodiment 1. The same, but the difference is: the experimental device also includes an alarm device 7 . A buzzer 71 and a plurality of warning lamps 72 are arranged on the described warning device, and different warning lights correspond to different warning positions. The alarm light corresponding to the part flashes. Before the abnormal phenomenon or fault disappears, the buzzer will sound for 5 seconds every 5 minutes, and the alarm light will keep flashing. No more flashing, and the experimental device continues to work normally. Both the filter I and the filter II are made of porous media materials. The pipelines in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com