Stirling engine based on repeated piston heating

A Stirling engine and piston technology, which is applied in the field of Stirling engines based on repeated piston heating, can solve the problems of less consideration of the comprehensive utilization of the hot end and the cold end, and achieve a good market prospect, reduce the temperature, and increase the temperature difference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

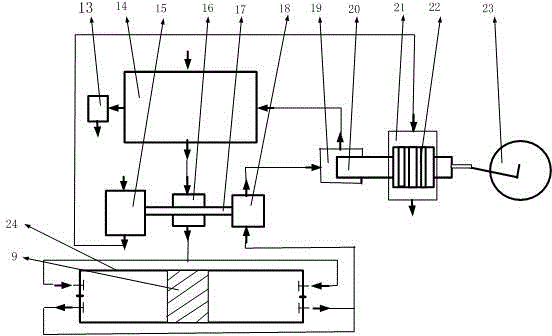

[0022] Such as figure 1 As shown, a Stirling engine based on repeated piston heat supply, which includes exhaust gas treatment device, heat exchanger, refrigeration device, compressor, transmission shaft, turbine, Stirling hot end heating chamber, Stirling hot end , Stirling cold end refrigeration chamber, Stirling cold end, flywheel, gas generator, in which the inlet of the heating side of the heat exchanger is the inlet of gas and air mixture, the outlet of the heating side of the heat exchanger, and the inlet of the compressor , compressor outlet, gas generator inlet, gas generator outlet, turbine inlet, turbine outlet, Stirling hot end heating chamber inlet, Stirling hot end heating chamber outlet, heat exchanger cooling side inlet, heat exchanger The outlet on the cooling side, the inlet of the exhaust gas treatment device, etc. are connected through their respective chambers or conduits in turn; the inlet of the refrigeration device is the air inlet, the outlet of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com