Liquid conveying hose

A technology of liquid and tubular fabrics, which is applied in the direction of hoses, pipes, pipes/pipe joints/fittings, etc., which can solve the problems that the hose is difficult to flatten or fold, limit the length of the hose, and reduce the softness, so as to achieve convenient coiling Or folded storage, increase the delivery flow, the effect of good softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in detail below with reference to the accompanying drawings, in which like reference numerals denote like parts. In order to achieve the above purpose, the following technical solutions are adopted:

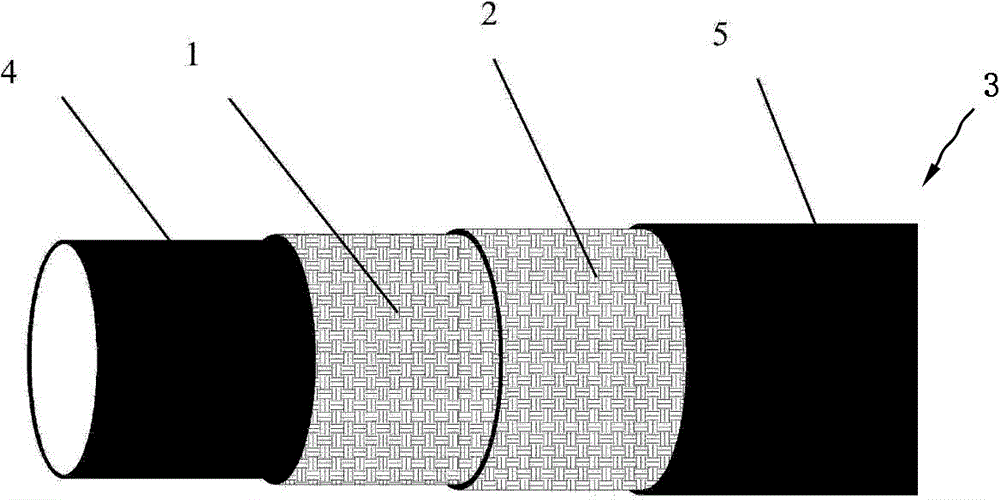

[0013] figure 1 It shows a schematic structural diagram of an embodiment of the liquid delivery hose 3 of the present invention, which includes: an inner rubber layer 4 , a tubular fabric layer 1 , a soft wire mesh layer 2 and an outer rubber layer 5 from inside to outside.

[0014] The inner rubber layer 4 and the outer rubber layer 5 are made of thermoplastic polyurethane body material or thermoplastic polyurethane added with additives.

[0015] The tubular fabric layer 1 can be plain weave, twill weave or satin weave structure. The plain weave structure is denser and the shape retention is better. As the floating point number increases in the twill weave, the enhancer layer becomes looser, but the pressure resistance performance will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com