Anode furnace oxido-reduction mouth brick hot-state replacement method and novel anode furnace

A replacement method and anode furnace technology, applied in the direction of lining repair, etc., can solve problems affecting production, affecting normal production operations, and affecting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

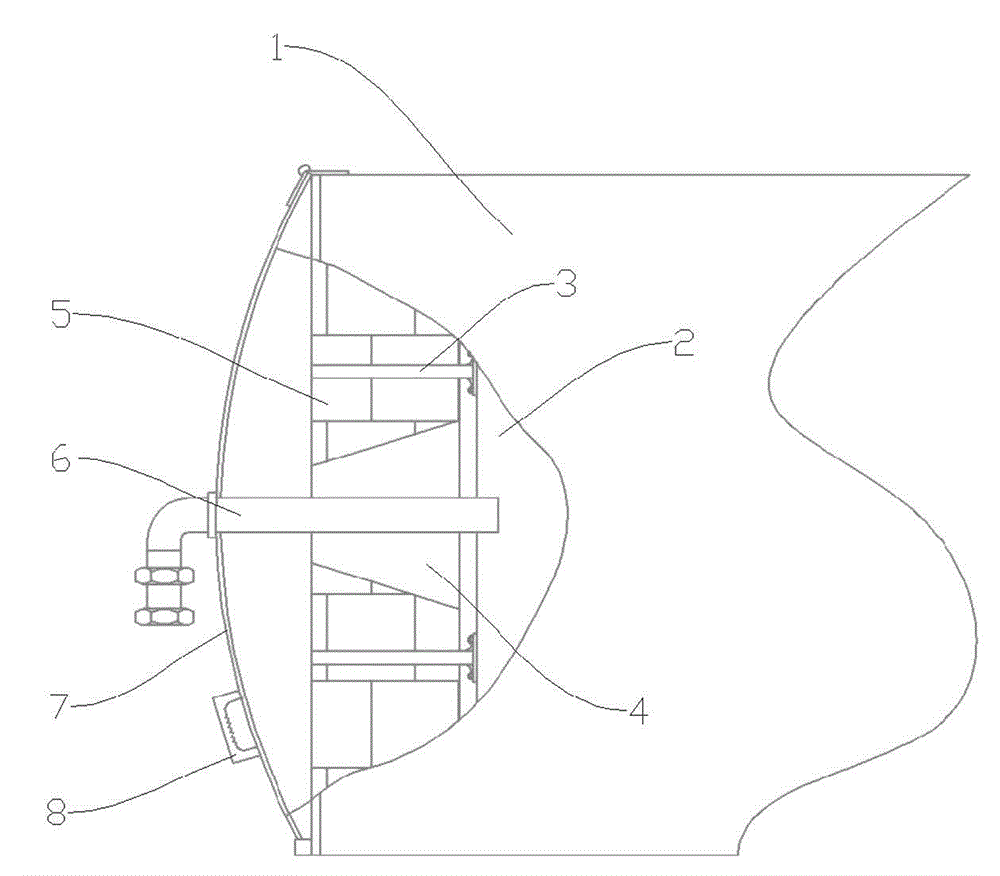

[0020] Such as figure 1 as shown,

[0021] A hot-state replacement method for an anode furnace oxidation-reduction brick, characterized in that: it is carried out in accordance with the following steps,

[0022] A, making rectangular steel plate mold 3, the steel plate mold is a hollow structure;

[0023] B, making conical refractory brick 4;

[0024] C. Weld the prepared steel plate mold to the inner steel shell at the redox port of the anode furnace;

[0025] D. Build the prepared conical refractory brick 4 in the steel plate mold, fill the area outside the conical refractory brick 4 with refractory mud and build square refractory bricks 5;

[0026] E. Install the arc-shaped movable steel plate 7 of the furnace shell, and use clips to lock it;

[0027] F. Install the redox tube 1, the redox tube 6 passes through the arc-shaped movable steel plate 7 of the furnace shell and the conical refractory brick 4 and enters the reaction furnace 2, and the anode furnace can gradual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com