FPD/TP positive photoresist used for flexible substrate

A positive photoresist and flexible technology, applied in the field of photoresist, can solve the problems of poor adaptability, poor chemical resistance, low resolution, etc., and achieve the effect of simple production, high resolution and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

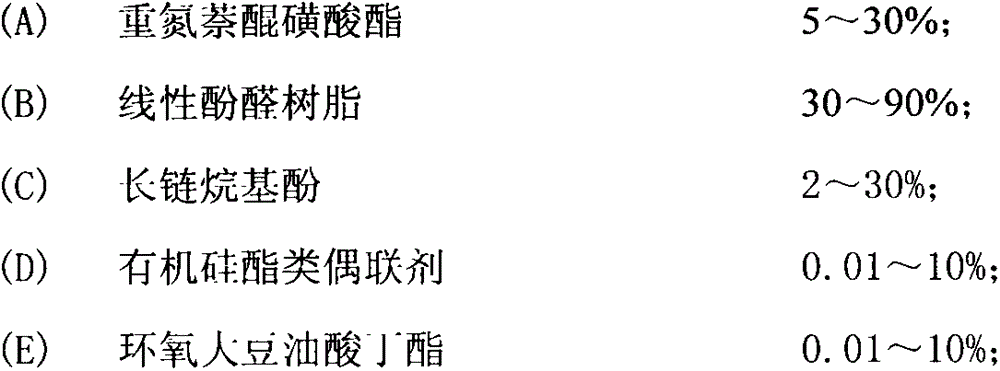

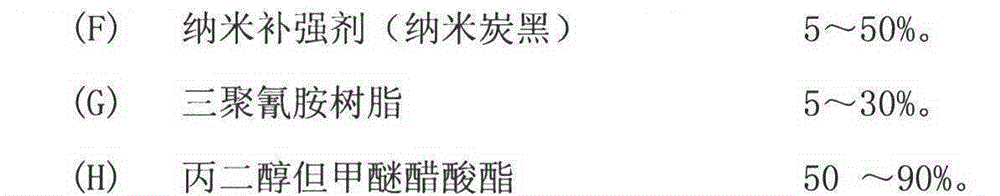

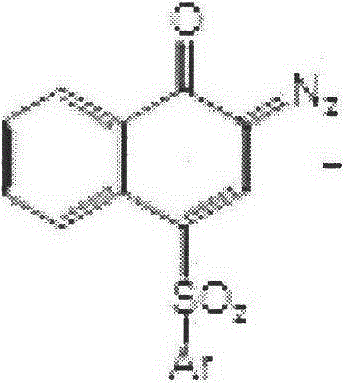

[0028] In the photoresist of the present invention, diazonaphthoquinone sulfonate is used as a sensitizer, and the mass percentage content is preferably 5-30%. When the content of the diazonaphthoquinone sulfonate is lower than 5% or higher than 30% by mass, the photosensitive performance of the photoresist is not ideal, and underexposure or overexposure is likely to occur, resulting in unsatisfactory graphics after development.

[0029] Among them, linear phenolic resin, thermoplastic polymer formed by polycondensation of cresol and formaldehyde under the action of acid catalyst, molecular weight: Mn: 1000-1100; Mw: 5000-6000. Softening point: 140~160. The molecular weight is too high or too low, will affect the alkali dissolution rate of the photoresist in dilute alkali after film formation

[0030] Long-chain alkylphenol, a mixture of alkylphenols with carbon atoms between 10`20 in the molecule. Due to the long carbon chain in the molecule, it plays a certain flexibility in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com