Low-interference food processing machine

A food processing machine, food processing technology, applied in the direction of program control, control/regulation system in instruments, sequence/logic controllers, etc., can solve the problems of increased cost, complex circuit structure, and increased volume of anti-electromagnetic interference devices, Achieve the effect of solving electromagnetic interference problems and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

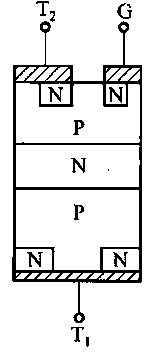

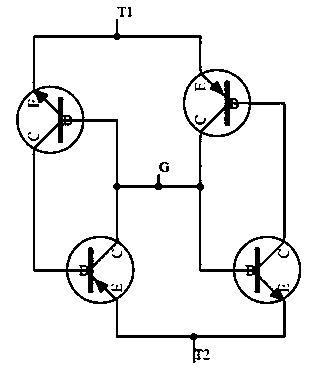

[0035] A low-interference food processing machine of the present invention includes a control circuit, the control circuit includes a load for food processing, a load circuit for driving the load, and a control chip, the load circuit includes a switch, and the switch is thyristor, wherein the control chip controls the thyristor in a drop-wave manner, the control chip controls the thyristor with a trigger pulse, and the rising edge of the trigger pulse is at the zero-crossing point of the power supply voltage, so The above trigger pulse is maintained until the rate of change of the power supply voltage is minimum.

[0036] In this embodiment, the load is a heating device, the thyristor is a triac, the control chip controls the heating device by triggering the thyristor, and the control chip triggers the Before the thyristor, the control chip needs to detect the zero-crossing point of the power supply through a zero detection circuit, and the control chip outputs a trigger pulse...

Embodiment 2

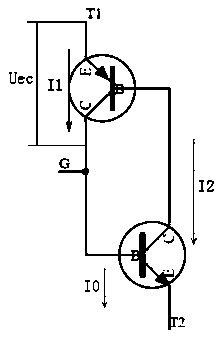

[0049] The difference with the above-mentioned embodiment 1 is that, as figure 2 As shown, the control circuit includes a power supply voltage detection circuit, and the control chip detects the power supply voltage at an interval time t1 through the power supply voltage detection circuit, and calculates the voltage rising slope of the two detection voltages before and after each time interval, so as to obtain the power supply voltage The minimum voltage change rate.

[0050] When the AC positive half-wave is input, after the resistors R11 and R12 divide the voltage, and the capacitor C8 filters, the control chip detects the Vad voltage at an interval of t (t=100us), and calculates the voltage rising slope of the two detection voltages vad1 and vad2 before and after k= (vad2-vad1) / t, when K=0, remove the trigger pulse.

Embodiment 3

[0052] The difference between this embodiment and the above-mentioned embodiment 1 is that, as image 3 As shown, the load includes a heating device and a motor, and the load circuit includes a heating control circuit, a motor control circuit, the heating control circuit, and a motor control circuit. In this embodiment, the heating control circuit and the motor control circuit are connected in parallel between the power supply, the motor control circuit includes an anti-electromagnetic interference circuit and a motor drive circuit, and the input end of the anti-electromagnetic interference circuit is electrically connected to the power supply, the output end of the electromagnetic interference circuit is electrically connected to the motor drive circuit.

[0053] Such as Figure 4 As shown, the anti-electromagnetic interference circuit includes:

[0054] A common mode inductor L1, the two input ends of the common mode inductor L1 are respectively connected to the live wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com