Photovoltaic power generation support mounting structure and photovoltaic power generation support construction method

A photovoltaic power generation and installation structure technology, applied in photovoltaic power generation, photovoltaic module support structure, photovoltaic modules and other directions, can solve the problems of hidden safety hazards and slow speed, and achieve the effect of protecting safety, preventing components from cracking, and shortening the installation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

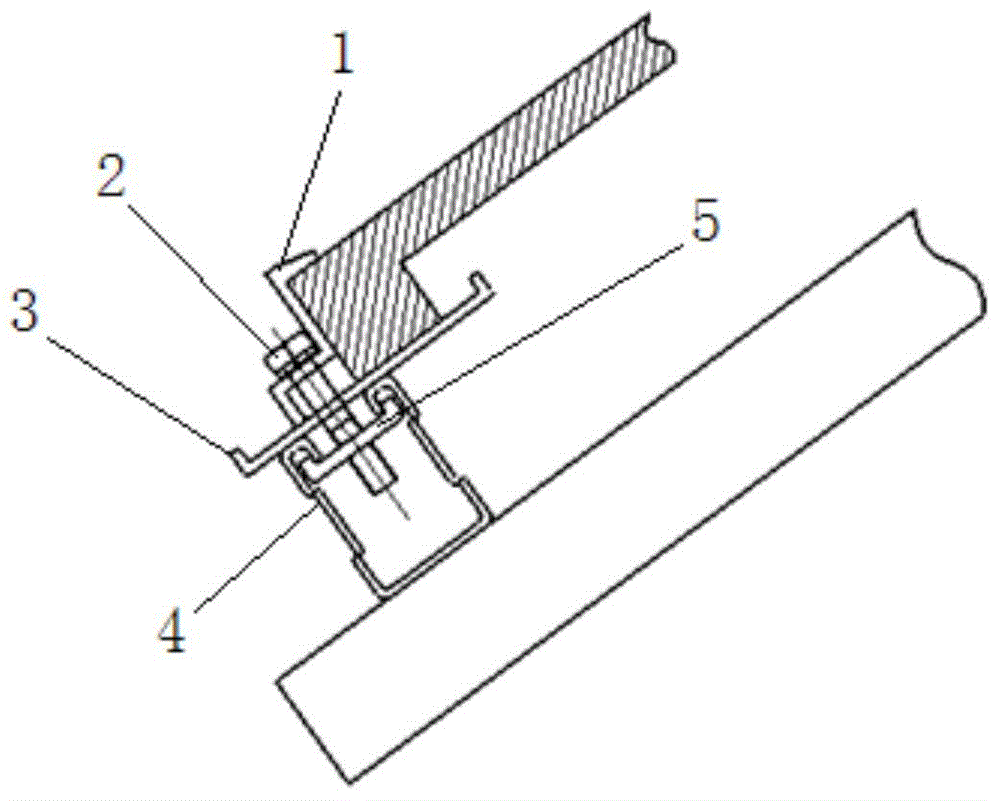

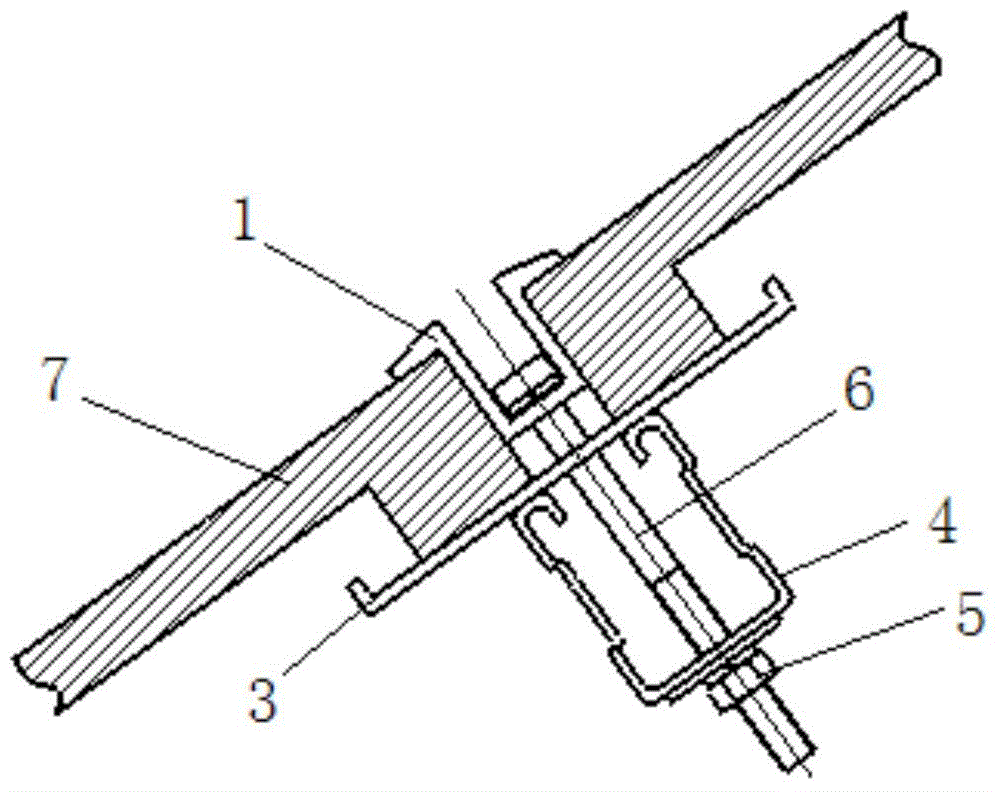

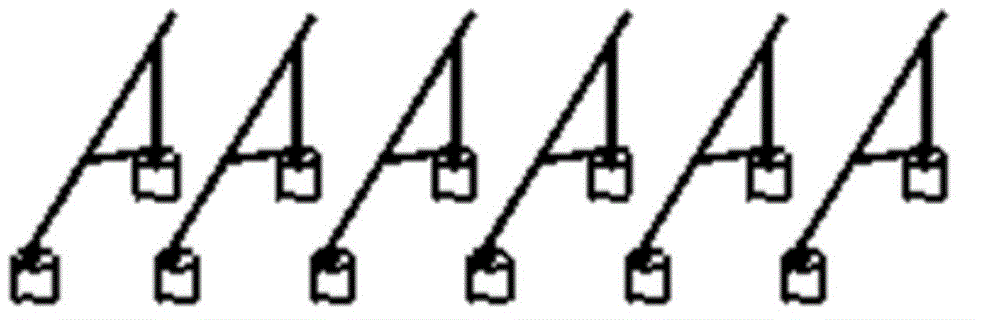

[0021] Such as Figure 1-Figure 4 As shown, a specific embodiment of the present invention, the photovoltaic power generation bracket installation structure, includes a pressing block 1, a concave gasket 3, a purlin 4, a square nut 5 and a long bolt 6, and the long bolt 6 passes through the pressing block 1 and the purlin 4 in sequence It is fixedly connected with the square nut 5, and the pressure block 1 cooperates with the upper and lower rows of photovoltaic modules 7 through the pressing edges on both sides. A concave gasket 3 is arranged between the photovoltaic module 7 and the purlin 4. Bolts, because the original installation structure can use short bolts, which does not affect the space for electrical pipes to pass through. The first row of photovoltaic modules still adopts the fixing method of the original installation structure. For photovoltaic modules that are far from the ground, such as the second and third Third, the installation of the fourth row of component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com