Fluorescent light source device

A light source device and fluorescence technology, applied in the direction of fluorescence, light source, electric light source, etc., can solve the problems of low thermal conductivity of barium sulfate, complex driving system structure, inability to obtain a long service life of the wheel motor 73, etc., and achieve the effect of high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach 》

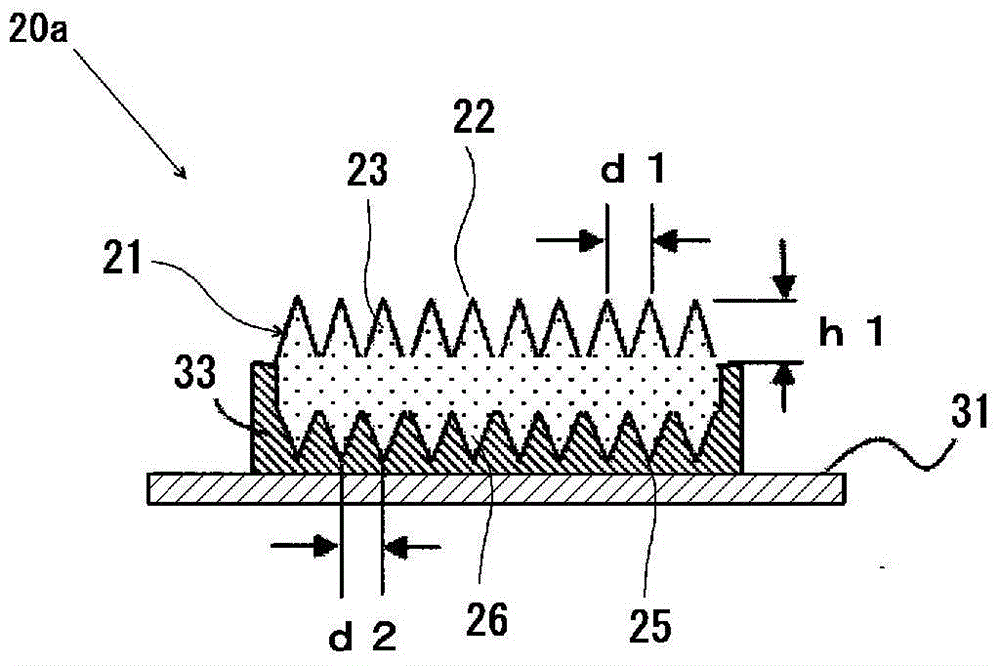

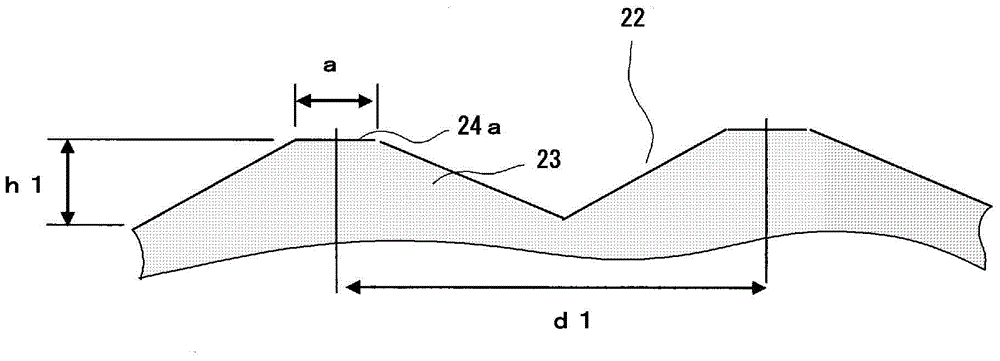

[0082] figure 2 It is an explanatory cross-sectional view showing the configuration of the fluorescent light emitting member in the fluorescent light source device according to the first embodiment of the present invention.

[0083] Fluorescent light emitting member 20a such as figure 2 As shown, on the surface of the rectangular substrate 31 ( figure 2 The upper surface of the upper surface) is provided with a wavelength conversion member composed of a substantially rectangular plate-shaped fluorescent member 21 .

[0084] The fluorescent light-emitting member 20a follows the surface of the fluorescent member 21 ( figure 2 The upper surface of the laser diode 10 is disposed so as to face the laser diode 10, and this surface serves as the excitation light receiving surface and also serves as the fluorescence emitting surface.

[0085] In addition, on the back of the fluorescent member 21 ( figure 2 The lower surface) and side surfaces are respectively provided with a ...

no. 2 Embodiment approach 》

[0161] Figure 8 It is an explanatory cross-sectional view showing the configuration of the fluorescent light emitting member in the fluorescent light source device according to the second embodiment of the present invention.

[0162] The fluorescent light emitting member 20b such as Figure 8 As shown, there is a rectangular substrate 31 and a wavelength conversion member formed of, for example, a rectangular plate-shaped fluorescent member 24 provided on the surface of the substrate 31 . In the fluorescent light-emitting member 20b of this example, the surface of the wavelength converting member ( Figure 8 The upper surface in the middle) becomes the light-receiving surface of the excitation light. The surface of the wavelength conversion member functions not only as an excitation light receiving surface, but also as a light emitting surface. Furthermore, on the excitation light receiving surface of the wavelength conversion member, that is, on the surface of the fluores...

no. 3 Embodiment approach 》

[0210] Figure 13 is an explanatory perspective view showing the configuration of the fluorescent light emitting member of the fluorescent light source device according to the third embodiment of the present invention, Figure 14 yes Figure 13 A cross-sectional view for explaining the fluorescent light-emitting member shown.

[0211] Fluorescent light emitting member 20c such as Figure 13 In the figure shown, a wavelength conversion member 122 composed of a rectangular flat fluorescent member is bonded to the surface of a rectangular flat substrate 121 via a rectangular bonding metal layer 129, and the peripheral side of the wavelength conversion member 122 is covered. A reflective layer 128 is formed in a manner.

[0212] The surface of the wavelength converting member 122 of the fluorescent light emitting member 20c ( Figure 14 The upper surface) becomes the excitation light receiving surface. In addition, the surface of the wavelength converting member 122 functions...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com