Process method and device for producing sodium hydrosulfide from acid gas

A process method, the technology of sodium hydrosulfide, applied in chemical instruments and methods, sulfur compounds, separation methods, etc., can solve the problems of low operation efficiency, difficult operation of the device, long process, etc., to ensure long-term operation and prevent crystallization. The effect of precipitation and improving the depth of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

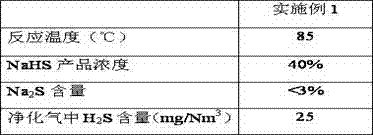

Embodiment 1

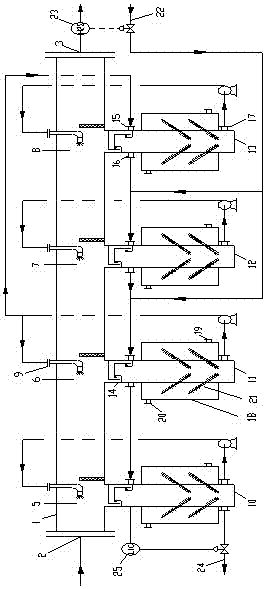

[0050] use as figure 1 The process device shown uses acid gas and lye with a mass concentration of 35% as raw materials to carry out two-stage acid-base reaction.

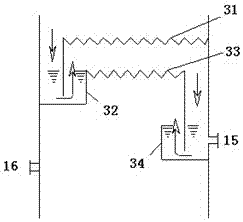

[0051] When using the pipeline reactor of the present invention to treat acid gas, the acid gas enters the primary reaction zone in the reaction pipeline through the inlet, and reacts with the reaction product liquid from the primary liquid storage tank (the reaction product liquid overflowed from the secondary liquid storage area) In order to absorb the liquid, a liquid film in the direction of the axis is formed in the reaction pipe through the nozzle. When the acid gas passes through the liquid film, a neutralization reaction occurs. Under the action of the gravity field, the liquid film is sprayed onto the wall of the reaction pipe, along the The wall enters the primary liquid storage tank after passing through the liquid seal assembly. After the liquid film is sprayed onto the tube wall, the liquid is prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com