Casting connector of 500-diameter section dummy bar head

A technology of connectors and ingot heads, which is applied in the field of iron and steel metallurgical continuous casting, can solve the problems of cold material accumulation, dummy head difficult to take off the ingot, etc., and achieve the effect of low cost, simple and reliable structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the accompanying drawings.

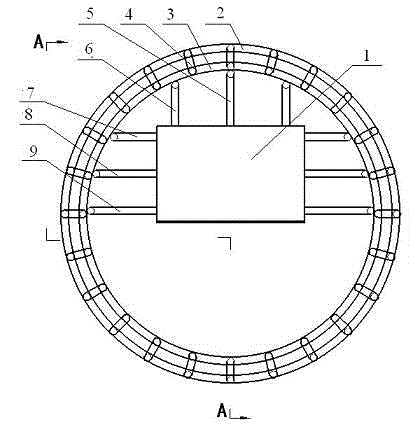

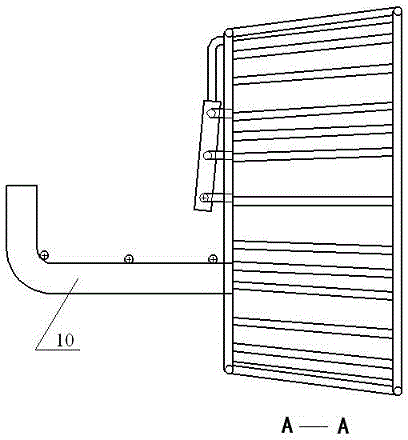

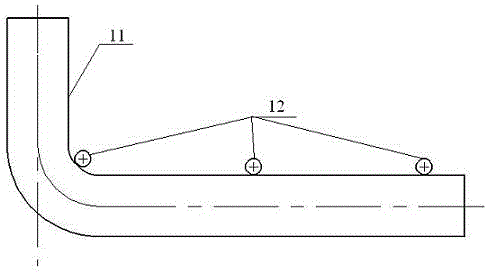

[0022] Such as figure 1 — Figure 4 , a Φ500 section surface dummy head pouring connector, including a steel bar frame, a backing plate 1 and a hook head 10, the steel bar frame is a frustum-shaped steel bar cage welded by 26 Φ10 round steels, specifically a A Φ10 round steel 2 with a length of 1383 mm is used as the top beam of the steel cage, a Φ10 round steel 3 with a length of 1257 mm is used as the bottom beam of the steel cage, and 24 Φ10 round steel 4 with a length of 205 mm are used as the The connecting beam between the top beam and the bottom beam, wherein the diameter of the top beam is 400 mm, the diameter of the bottom beam is 450 mm, and all the connecting beams are evenly distributed between the top beam and the bottom beam at an angle of 15°. The backing plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com