Tool for laser welding of printed circuit heat exchanger

A printed circuit board, laser welding technology, used in laser welding equipment, welding equipment, welding equipment and other directions, can solve the problems of uneven force, damage to laser welding connection strength, small force, etc., to achieve the effect of tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

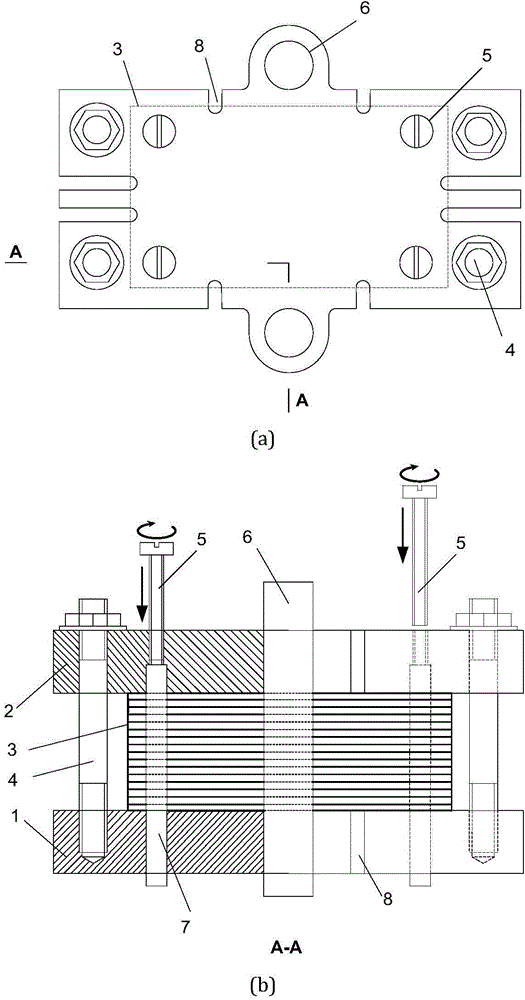

[0027] Such as figure 1 As shown in (a), this embodiment includes: a base 1, a top cover 2, a PCHE metal heat exchange plate 3, a stud 4, a pin-off screw 5, a guide rod 6, a positioning pin 7, and a welding groove 8, and laser welding is performed Before that, the positioning pin 7 and the guide rod 6 are put into the base first, and then the PCHE metal heat exchange plate is aligned with the positioning pin 7 and the guide rod 6 and stacked on the base. After all the PCHE metal heat exchange plates are installed, the top cover is aligned with the positioning pin 7 and the guide rod 6 and stacked on the PCHE metal heat exchange plate, and fastened with studs.

[0028] The base 1, the top cover 2 and the PCHE metal heat exchange plate 3 are aligned and fixed relative to each other through positioning pins and guide rods 6. The base 1 and the top cover 2 are connected by studs 4 to clamp the PCHE metal heat exchange plate 3 , and the guide rod 6 controls the direction of relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com