Polycrystalline silicon production method

A production method and polysilicon technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of high cauliflower ratio on the surface of silicon rods and low success rate of furnace start-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

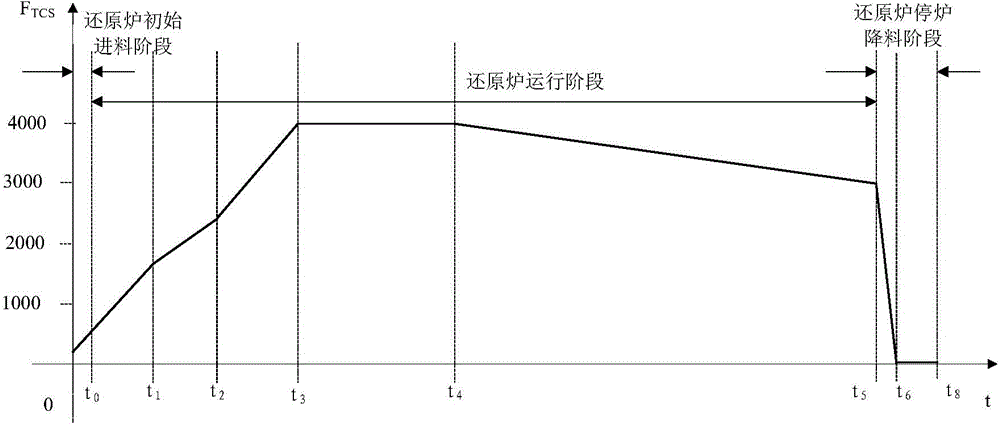

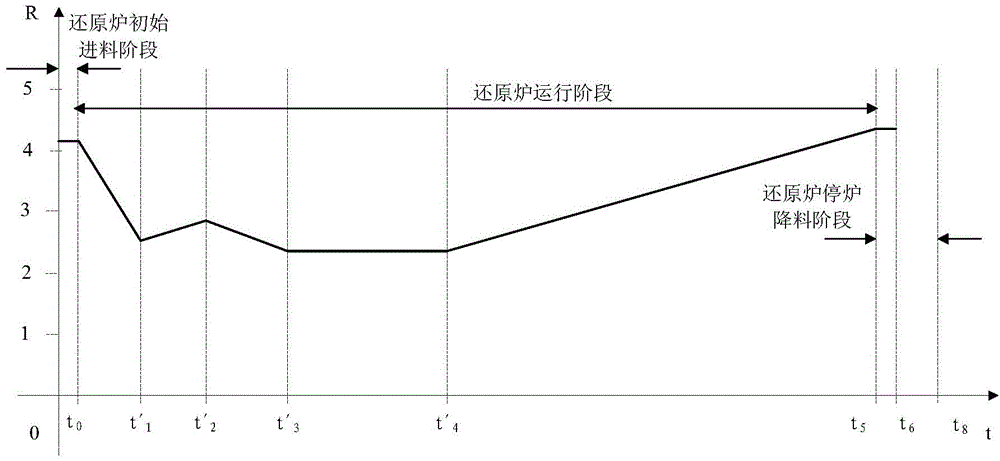

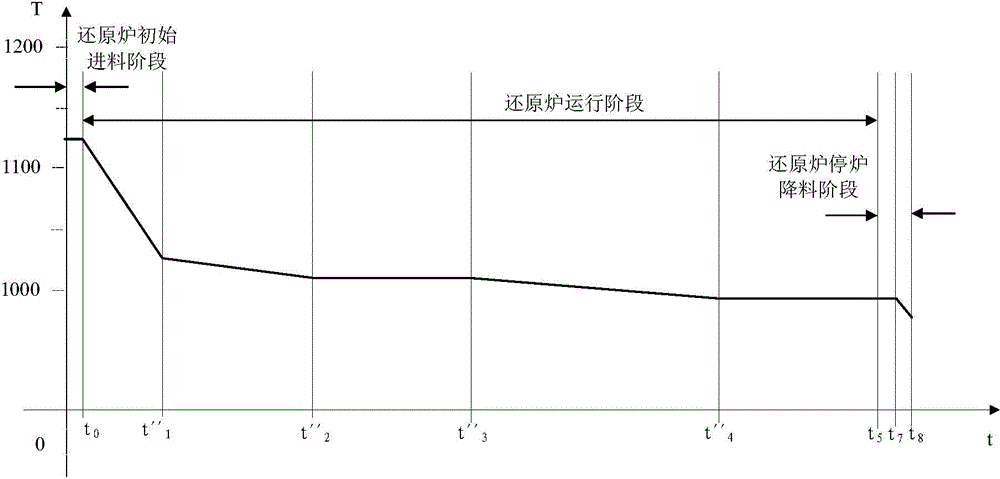

[0174] In 36 pairs of rod reduction furnaces, 21 nozzles are evenly distributed, and the diameter of each nozzle is 9mm. The initial temperature of the reduction furnace was set at 1130°C. In the initial feeding stage of the reduction furnace, the amount of trichlorosilane F TCS According to the following curve F TCS =150t+150(0≤t≤1) into the heat exchanger, preheat the hydrogen to 80°C, and pass the hydrogen into the heat exchanger according to the following flow rate: F H2 =0.0149*F TCS *R, where the molar ratio R of hydrogen and trichlorosilane flow is maintained at 4.30, and the mixed gas of hydrogen and trichlorosilane is exchanged with high-temperature water and reaction tail gas in the heat exchanger to 100°C Pass it into the reduction furnace to carry out the polysilicon deposition reaction, keep the temperature in the reduction furnace (1130°C) constant, and react for 1 hour.

[0175] In the operation stage of the reduction furnace, the amount of trichlorosilane m...

Embodiment 2

[0208] In the 36 pairs of rod reduction furnaces, 21 nozzles are evenly distributed, and the diameter of each nozzle is 9mm. The initial temperature of the reduction furnace was set at 1110°C. In the initial feeding stage of the reduction furnace, the amount of trichlorosilane F TCS According to the following curve F TCS =161.1t+138.9(0≤t≤1) into the heat exchanger, preheat the hydrogen to 80°C, and pass the hydrogen into the heat exchanger according to the following flow rate: F H2 =0.0149*F TCS*R, where the molar ratio R of hydrogen and trichlorosilane flow is maintained at 4.2, and the mixed gas of hydrogen and trichlorosilane is exchanged with high-temperature water and reaction tail gas in the heat exchanger to 100°C Pass it into the reduction furnace to carry out the polysilicon deposition reaction, keep the temperature in the reduction furnace (1110°C) constant, and react for 1 hour.

[0209] In the operation stage of the reduction furnace, the amount of trichlorosi...

Embodiment 3

[0238] In 36 pairs of rod reduction furnaces, 21 nozzles are evenly distributed, and the diameter of each nozzle is 9mm. The initial temperature of the reduction furnace was set at 1110°C. In the initial feeding stage of the reduction furnace, the amount of trichlorosilane F TCS According to the following curve F TCS =145t+10(0≤t≤2) into the heat exchanger, preheat the hydrogen to 80°C, and pass the hydrogen into the heat exchanger according to the following flow rate: F H2 =0.0149*F TCS *R, where the molar ratio R of hydrogen and trichlorosilane flow is maintained at 4.2, and the mixed gas of hydrogen and trichlorosilane is exchanged with high-temperature water and reaction tail gas in the heat exchanger to 100°C Pass it into the reduction furnace to carry out the polysilicon deposition reaction, keep the temperature in the reduction furnace (1110°C) constant, and react for 2 hours.

[0239] In the operation stage of the reduction furnace, the amount of trichlorosilane ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com