Medium trace element fertilizer specialized for cereal crops and preparation method of medium trace element fertilizer

A technology of medium and trace element fertilizers and grains, applied in potash fertilizers, application, organic fertilizers, etc., can solve problems that have not been seen, achieve convenient product application, improve lodging resistance and other stress resistance, and facilitate large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention also discloses a preparation method of special medium trace element fertilizer for cereal crops, which comprises the following steps:

[0034] (1) Fully mix the silicon-calcium-potassium-magnesium fertilizer, glacial acetic acid and granulation additives in the mixer, and then spray and granulate in the granulator, the particle size is controlled 1-4.75mm, to obtain the granule A;

[0035] (2) Grind the biomass ash with a ball mill to a fineness of 150-200 mesh, and then mix the finely ground biomass ash, humic acid and granulation additives in the mixer, and then mix them in the granulator. Spray granulation in the process, the particle size is controlled 1-4.75mm, to obtain granule B;

[0036] (3) The granule A and the granule B are uniformly mixed in a mixer, and then dried with a dryer to control the moisture content to not more than 2% to obtain a special medium and trace element fertilizer for cereal crops.

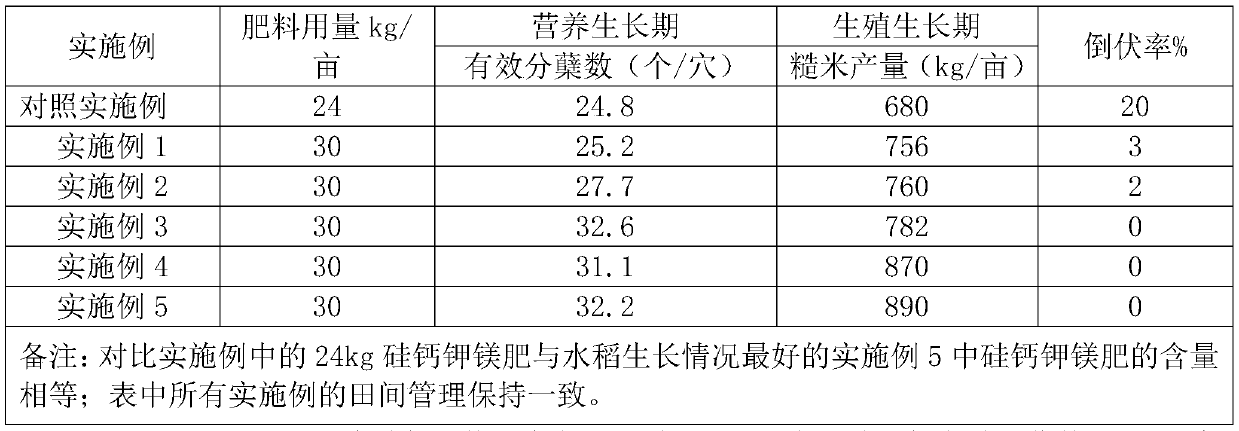

[0037] In actual use, the special medium-trace el...

Embodiment 1

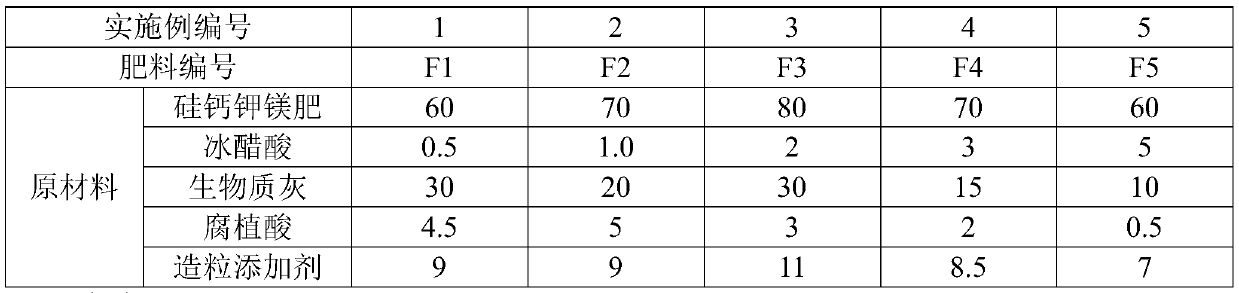

[0042] Example 1 Preparation of special medium and trace element fertilizer F1 for cereal crops:

[0043] S1. First, 60 kg of silicon-calcium-potassium-magnesium fertilizer, 0.5 kg of glacial acetic acid and 6 kg of granulation additives are mixed uniformly in the mixer, and then spray granulated in the granulator, the particle size is controlled 1-4.75mm, Get particle A;

[0044] S2. Grind the biomass ash with a ball mill to a fineness of 150 mesh, then mix the finely ground 30 kg biomass ash, 4.5 kg humic acid and 3 kg granulation additives in the mixer, and then Spray granulation in the granulator, the particle size is controlled 1-4.75mm to obtain granule B;

[0045] S3. Finally, granule A and granule B are uniformly mixed in a mixer, and then dried with a dryer to control the moisture content to 2% to obtain a special medium-trace element fertilizer for cereal crops.

Embodiment 2

[0046] Example 2 Preparation of special medium and trace element fertilizer F2 for cereal crops:

[0047] S1. Firstly, 70 kg of silicon-calcium-potassium-magnesium fertilizer, 1 kg of glacial acetic acid and 7 kg of granulation additives are thoroughly mixed in the mixer, and then spray granulated in the granulator, the particle size is controlled 1-4.75 mm, get particle A;

[0048] S2. Grind the biomass ash with a ball mill to a fineness of 150 mesh, and then mix the ground 20 kg of biomass ash, 5 kg of humic acid and 2 kg of granulation additives in the blender. Then Spray granulation in a granulator, the particle size is controlled 1-4.75mm to obtain granule B;

[0049] S3. Finally, granule A and granule B are uniformly mixed in a mixer, and then dried with a dryer to control the moisture content to 2% to obtain a special medium-trace element fertilizer for cereal crops.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com