Controlling Manufacturing Plants with Manufacturing Execution Systems

A technology for manufacturing factories and factories, which is applied in the direction of manufacturing computing systems, general control systems, control/regulation systems, etc., and can solve problems such as inability to represent equipment objects, heavy work processes and rules, and no logical connection in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

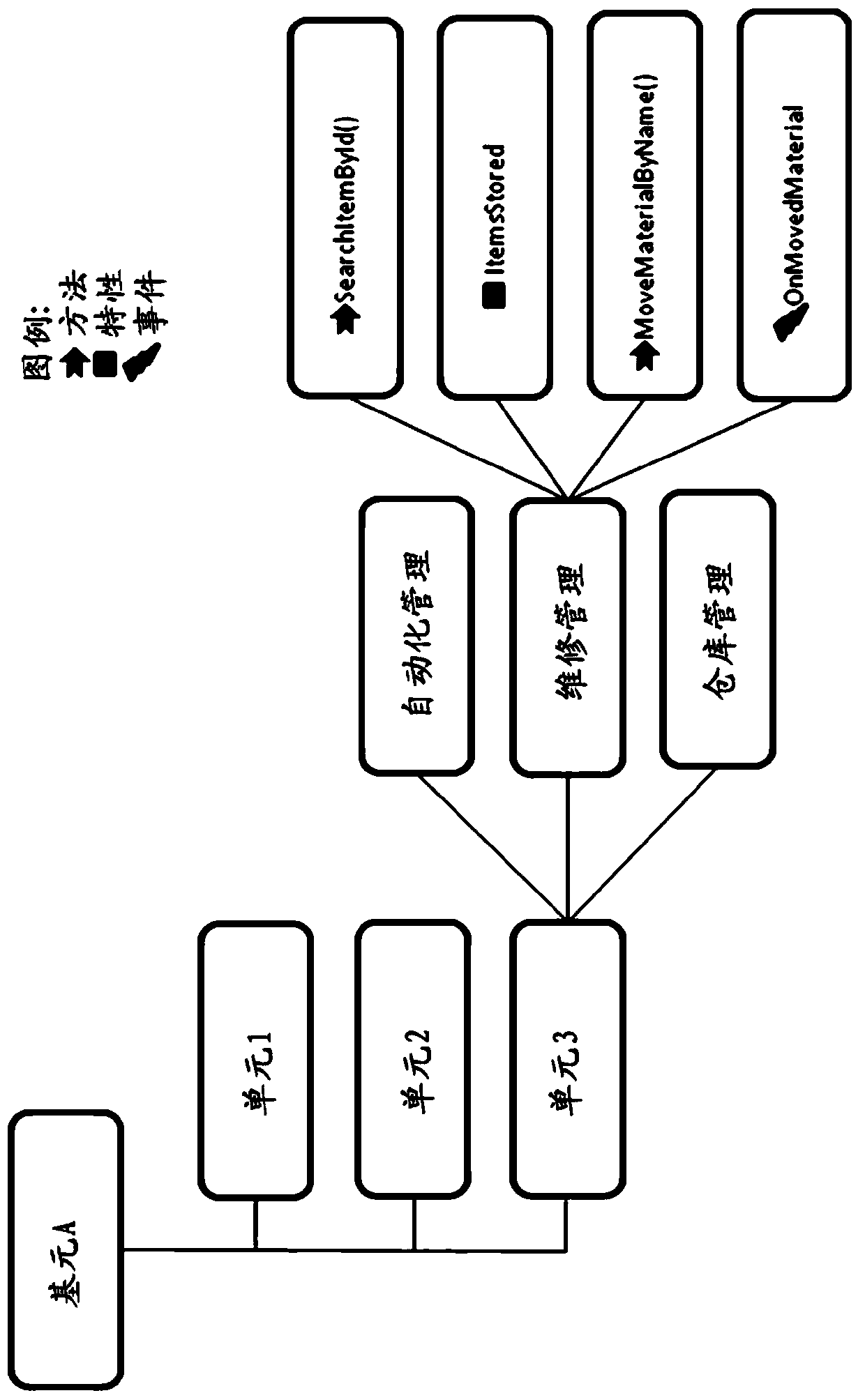

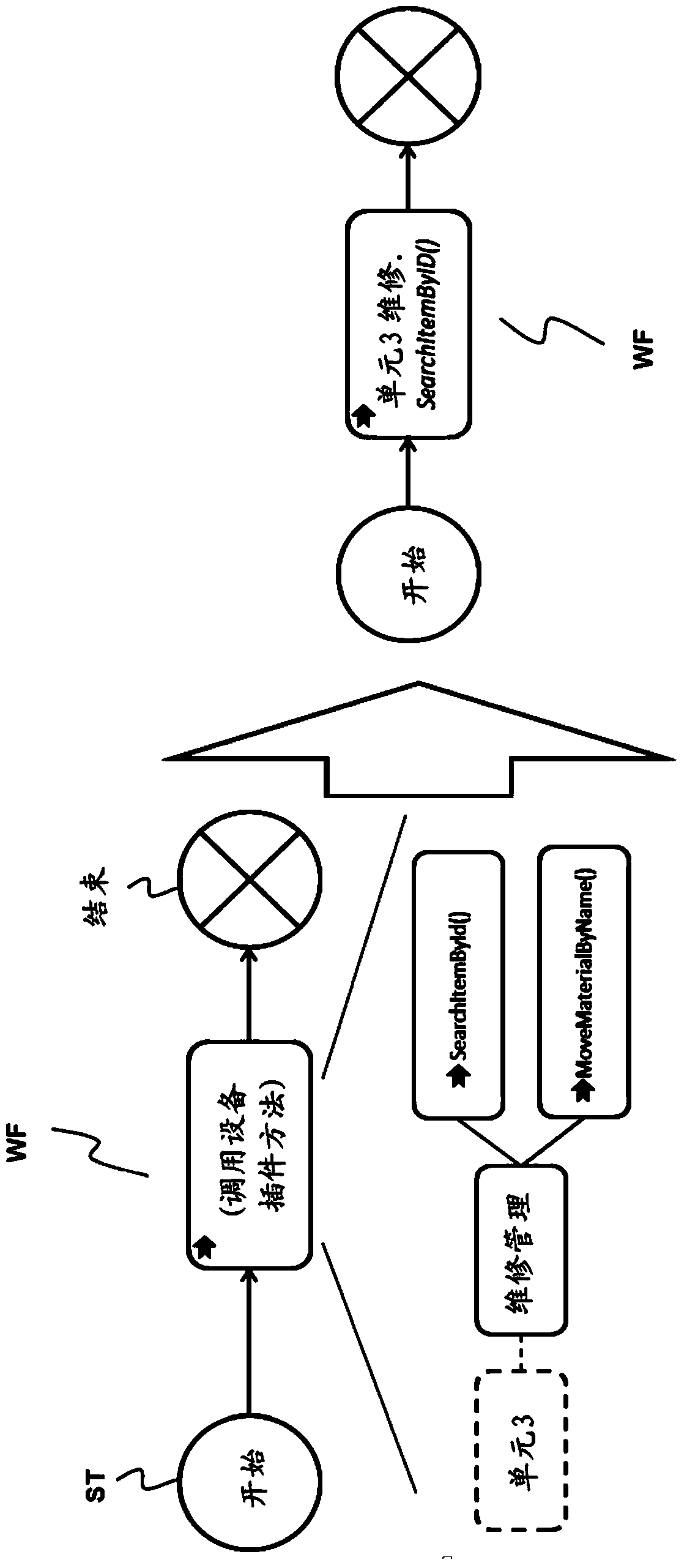

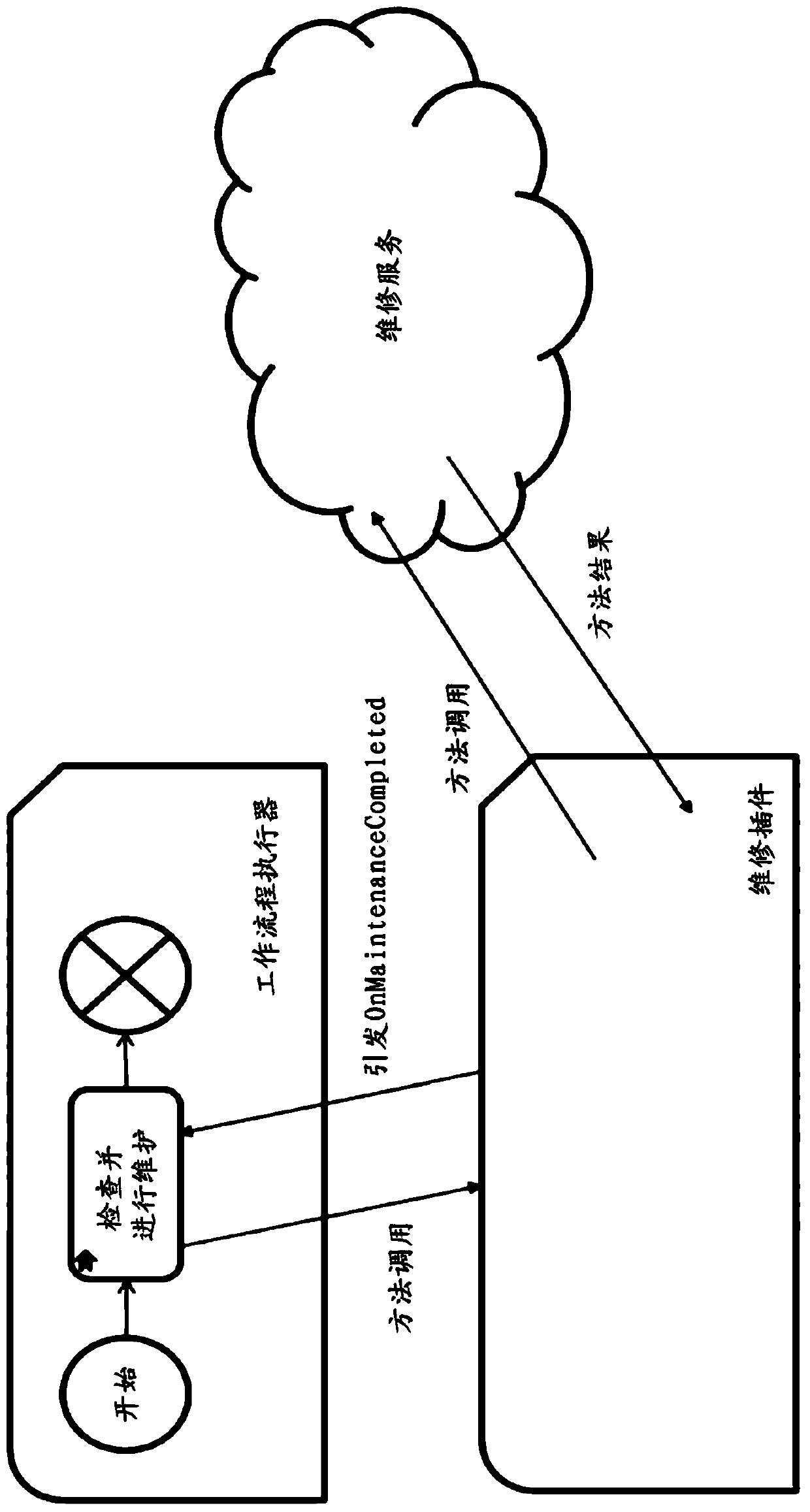

[0050] At least some embodiments of the present invention address the above-mentioned problems in which a manufacturing plant is controlled with an MES system by executing a given workflow that satisfies a given customer requirement.

[0051] An application called Plant Designer is provided to model a representation of a manufacturing plant by a set of equipment objects and by at least one workflow.

[0052] The equipment object is the collector of information, preferably it may be in the form of a record in a database table, where each field may conveniently define a given equipment attribute.

[0053] Composite entities called plugins are provided to extend the characteristics of device objects. A plug-in makes visible an interface that includes configuration, a set of property elements, a set of functional elements, and optionally a set of events.

[0054] especially:

[0055] Configuration enables system engineers to define plug-in behavior, such as making that function,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com