Adsorption resin

An adsorption resin and technical solution technology, applied in the field of resin, can solve the problems of uneven and reasonable pore size distribution, weak adsorption capacity, and low mechanical strength, and achieve uniform and reasonable pore size distribution, strong elution regeneration ability, and good mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

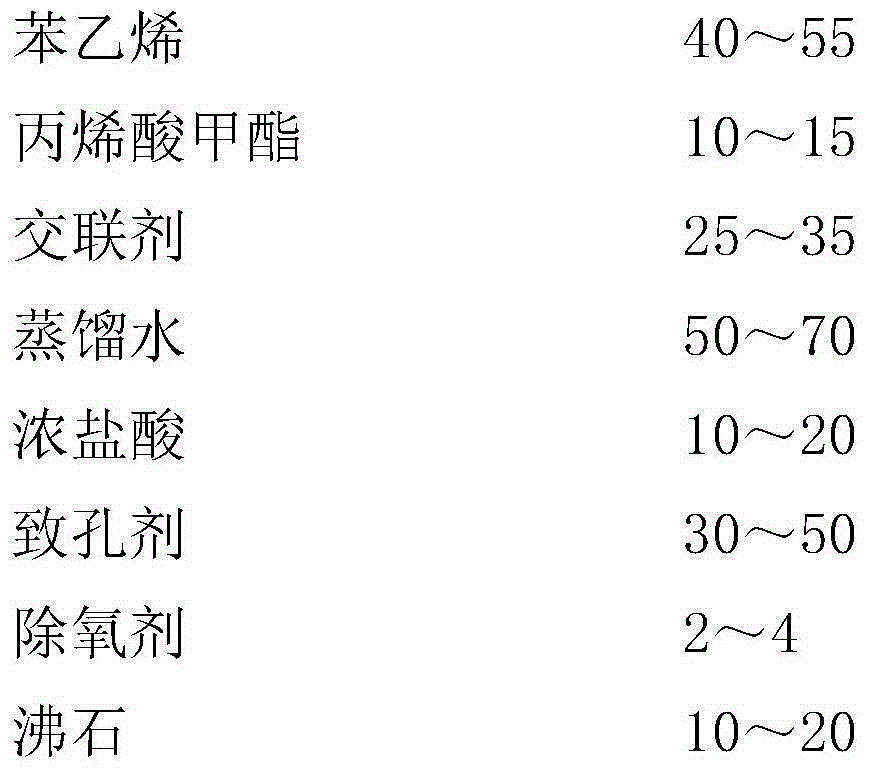

[0017] An adsorption resin comprising the following components in parts by weight,

[0018]

[0019] The porogen is a mixture of toluene and n-heptane, and the mixing ratio of toluene and n-heptane is 1:2.2.

Embodiment 2

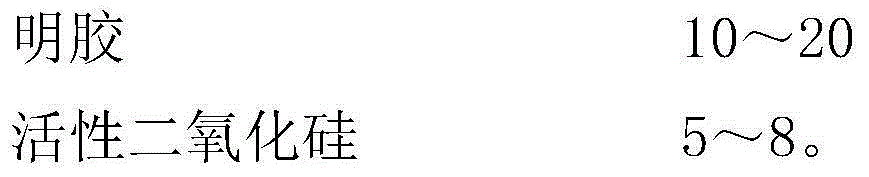

[0021] An adsorption resin comprising the following components in parts by weight,

[0022]

[0023]

[0024] The porogen is a mixture of toluene and n-heptane, and the mixing ratio of toluene and n-heptane is 1:2.8.

Embodiment 3

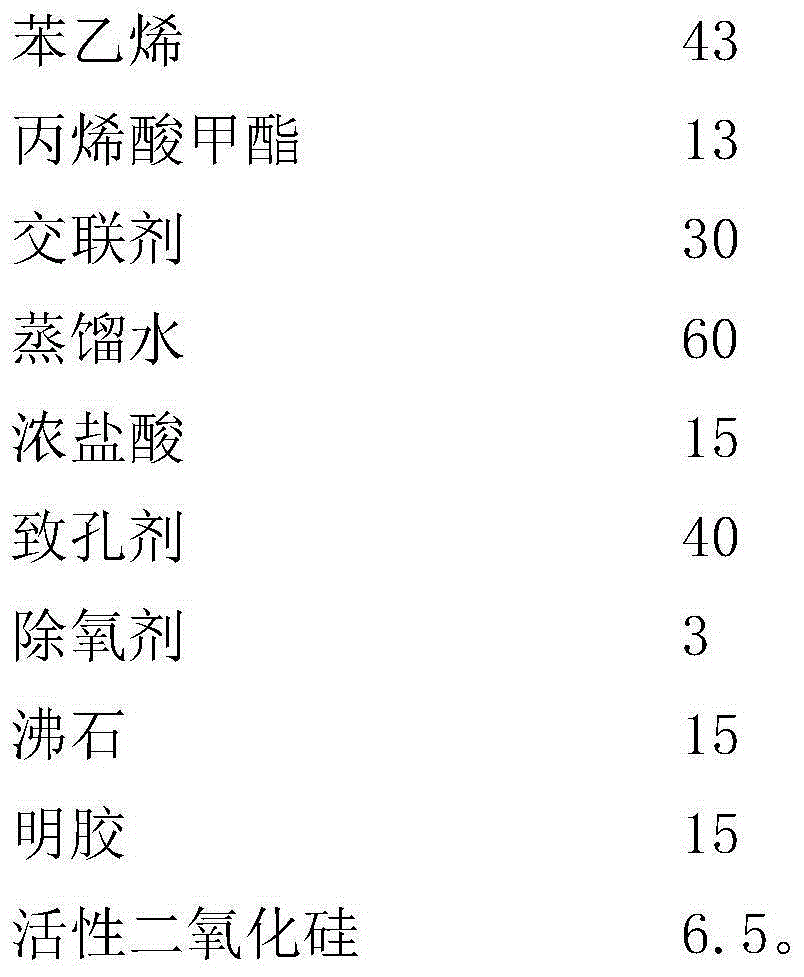

[0026] An adsorption resin comprising the following components in parts by weight,

[0027]

[0028] The porogen is a mixture of toluene and n-heptane, and the mixing ratio of toluene and n-heptane is 1:3.5.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap