Harmless treatment method of electrolytic manganese chromium slag

A technology of electrolytic manganese-chromium slag and harmless treatment, which is applied in the field of metallurgy, can solve the problems of electrolytic manganese-chromium slag accumulation and other problems, and achieve the effects of large processing capacity, reduced hazard impact, and easy transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

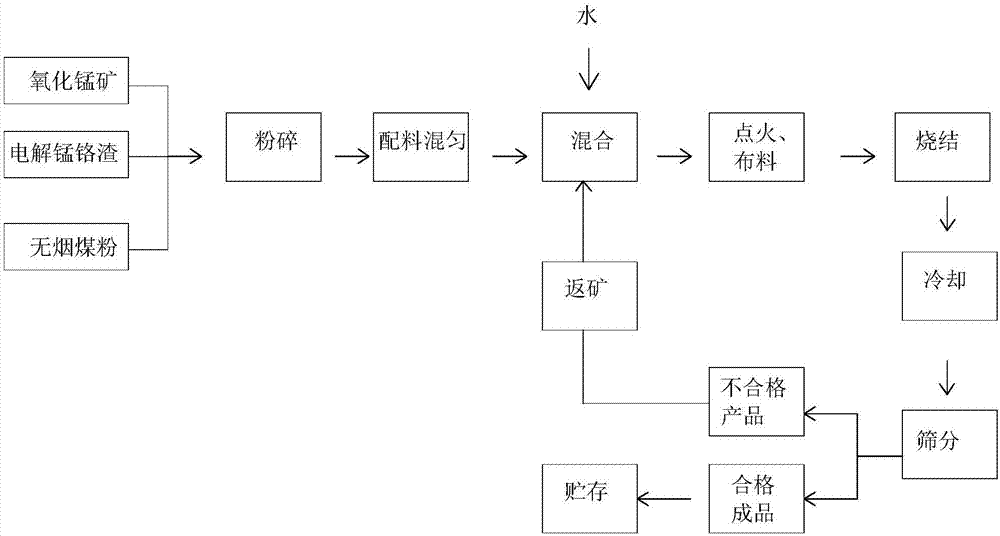

[0026] The method for harmless treatment of electrolytic manganese chromium slag comprises the following steps:

[0027] (1) Pretreatment: crush manganese oxide ore, electrolytic manganese chromium slag and anthracite coal powder to a particle size of 5mm, then add electrolytic manganese chromium slag: manganese oxide ore at a weight ratio of 1: 6, and add electrolytic manganese The total mass of chromium slag, manganese oxide ore and returned ore is 30% of the returned ore, and anthracite powder accounting for 14% of the total mass of electrolytic manganese-chromium slag and manganese oxide ore is added, and the mixture is obtained by shoveling and mixing for 4 times by stacking cone method , then add water so that the moisture content of the mixture is 7%, set aside;

[0028] (2) Ignition and cloth: first put oiled paper and wood into the bottom of the sintering furnace, then ignite and burn the wood until it is charcoal-like, break it and spread it on the bottom of the sint...

Embodiment 2

[0032] The method for harmless treatment of electrolytic manganese chromium slag comprises the following steps:

[0033] (1) Pretreatment: crush manganese oxide ore, electrolytic manganese chromium slag and anthracite coal powder to a particle size of 4mm, then add electrolytic manganese chromium slag: manganese oxide ore at a weight ratio of 1:9, and add electrolytic manganese The total mass of chromium slag, manganese oxide ore and returned ore is 25% of the returned ore, and then anthracite coal powder accounting for 15% of the total mass of electrolytic manganese-chromium slag, manganese oxide ore and returned ore is added, and the ore is mixed 5 times by stacking cone method Obtain the mixture, then add water so that the water content of the mixture is 9%, for subsequent use;

[0034] (2) Ignition and cloth: first put the oiled plastic bag and wood into the bottom of the sintering furnace, then ignite and burn the wood until it is charcoal-like, break it and spread it on ...

Embodiment 3

[0038] The method for harmless treatment of electrolytic manganese chromium slag comprises the following steps:

[0039] (1) Pretreatment: crush manganese oxide ore, electrolytic manganese-chromium slag and anthracite coal powder to a particle size of 3 mm, then add electrolytic manganese-chromium slag: manganese oxide ore at a weight ratio of 1: 13, do not add back ore, and then After adding anthracite powder accounting for 14% of the total mass of electrolytic manganese-chromium slag, manganese oxide ore and returned ore, use the stacking cone method to shovel and mix 5 times to obtain a mixture, then add water to make the water content of the mixture 8%, and set aside;

[0040] (2) Ignition and cloth: first put the oiled hay and wood into the bottom of the sintering furnace, then ignite the wood until it is charcoal-like, break it and spread it on the bottom of the sintering furnace, with a height of 5.5cm, and then spread it on a layer Wood chaff with a thickness of 4.5cm, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap