All-position pipeline welding workstation

A welding workstation, all-position technology, applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., to achieve the effect of small rotational inertia, accurate positioning, and improve work accuracy and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

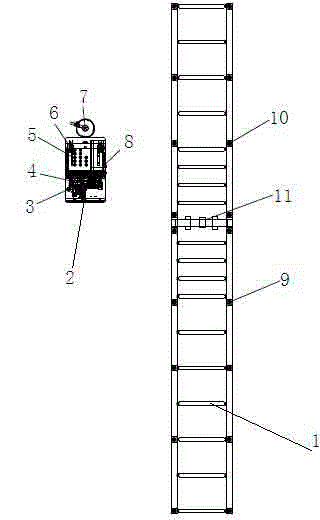

[0026] see figure 1 , an all-position pipeline welding workstation, the welding workstation includes a pipe cutting bevel device 1 and an open welding device 2, and the open welding device includes a welding chuck 4, an argon arc welding machine 5, a wire feeder 6, and a water tank 3 , argon cylinder 7, control electrical box 8, the pipe cutting and beveling device includes a front end 9 of a conveying line, a rear end 10 of a conveying line and a pipe cutting and beveling machine 11 arranged between the front end of the conveying line and the rear end of the conveying line. The technical scheme has a reasonable and compact structure and is easy to use. The joint use of the clamping welding device and the pipe cutting and breaking device can realize the purpose of cutting the pipe fittings, beveling and welding between the pipe fittings. It has the characteristics of flexible, convenient, safe and reliable disassembly. , It facilitates the operation, improves the welding quali...

Embodiment 2

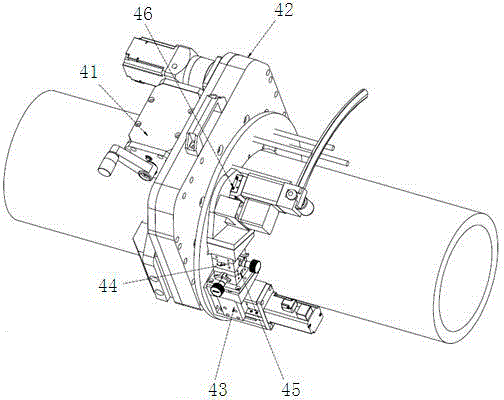

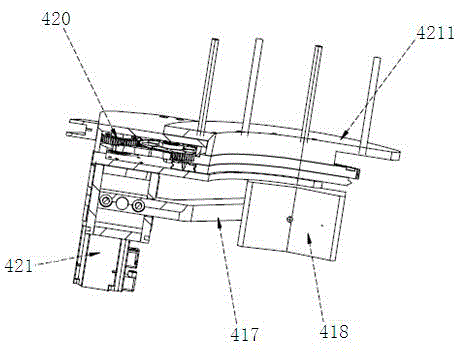

[0028] see figure 1 , figure 2 , as an improvement of the present invention, the welding chuck includes a pipe clamping mechanism 41, an open rotation mechanism 42, a welding torch swing mechanism 43, a manual slide mechanism 44 in the X direction, a manual slide mechanism 45 in the Y direction, and an automatic retreat mechanism. The needle mechanism 46, the pipe clamping mechanism 41 is fixed on the bottom of the open rotating mechanism 42 by bolts, the welding torch swing mechanism 43 is connected with the C-shaped rotating disk on the open rotating mechanism 42 using bolts, and the Y Direction manual slide mechanism 45 is connected with the trapezoidal nut slider on the welding torch swing mechanism 43, the X direction manual slide mechanism 44 is connected with the Y direction manual slide mechanism 45, and the automatic needle withdrawal mechanism 46 is connected with the X direction Manual slide mechanism 44 is connected. The welding chuck described in the technical ...

Embodiment 3

[0030] see figure 1 , figure 2 , as an improvement of the present invention, the welding chuck 4, argon arc welding machine 5, wire feeder 6, water tank 3, argon gas bottle 7, and control electric box 8 are installed on a movable trolley, and the welding chuck The head is set on one side of the mobile trolley, and the welding chuck is installed on the pipe to perform welding. Four casters are installed at the bottom of the mobile trolley, and two directional wheels and two universal wheels are set to facilitate movement and positioning. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com