Blanking manipulator

A manipulator and cutting technology, applied in the field of machinery, can solve the problems of high risk, high labor intensity of workers, and high enterprise cost, and achieve the effects of convenient maintenance and disassembly, reducing work intensity and enterprise cost, and improving positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

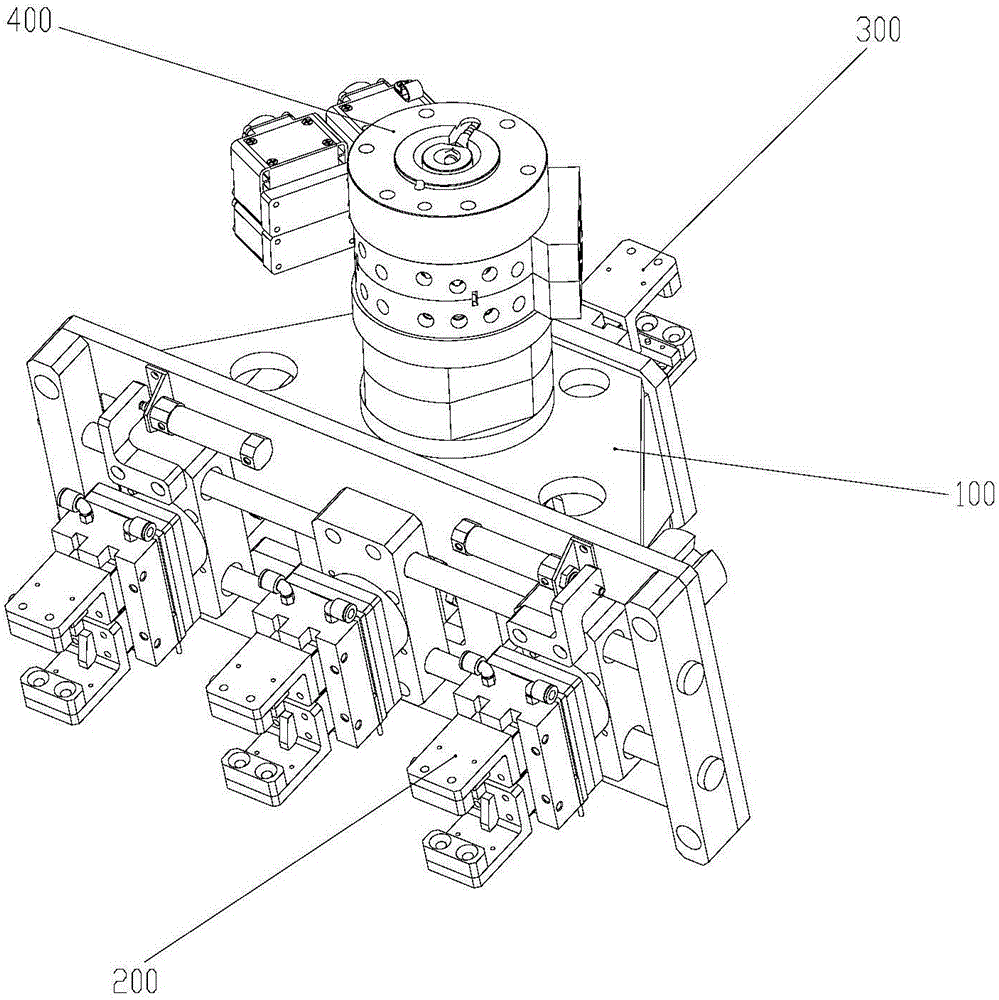

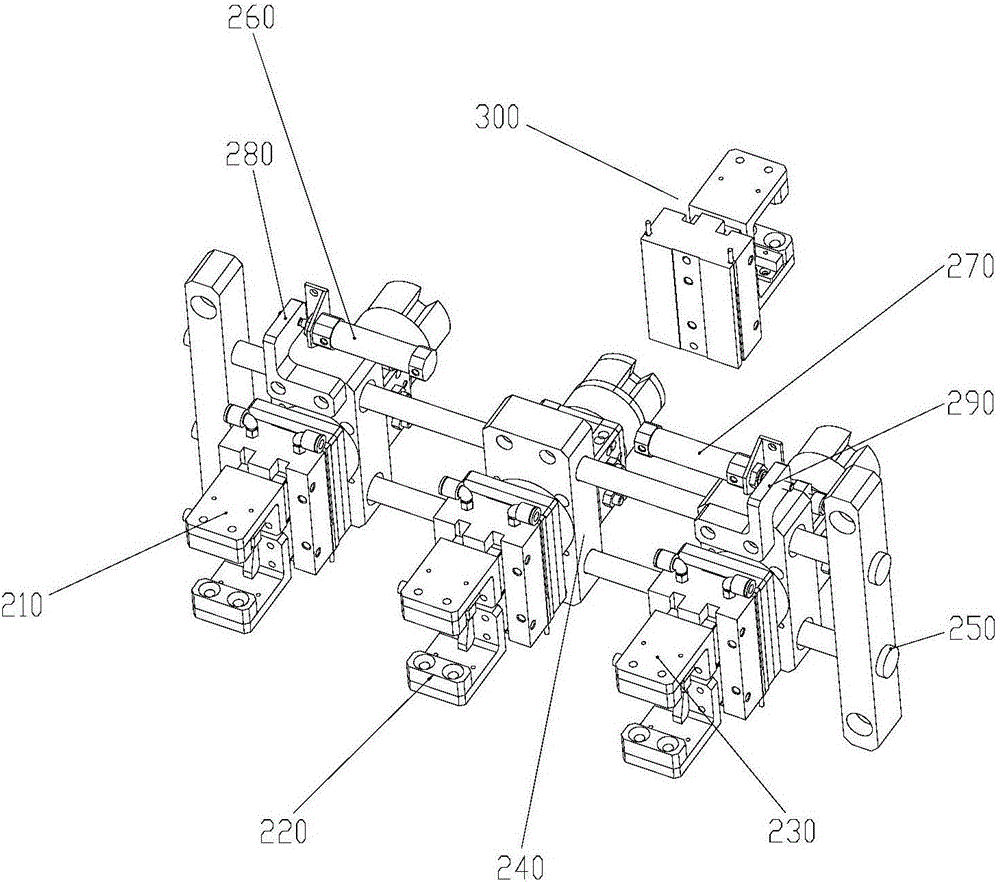

[0034] see figure 1 As shown, a blanking manipulator includes a frame 100, a three-handle assembly 200, a single-handle assembly 300, a gun changing tray 400 and a pneumatic control assembly (not shown in the figure), and the three-handle assembly 300 is set At the bottom of the frame 100, the single gripper assembly 300 is arranged on the top of the frame 100, the gun change tray 400 is arranged on the side of the frame 100, the pneumatic control assembly is arranged inside the frame 100, and the pneumatic control assembly controls the three gripper assembly 200 and the single gripper Hand assembly 100 movements. The setting of the gun change tray 100 allows the robot to quickly replace the mechanical gripper under different require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com