Locked rotor frequency conversion control method and device for drive motors

A technology for driving motors and control methods, which is applied to control driving, electric vehicles, power management, etc., can solve problems such as torque command value distortion, vehicle jitter, etc., to solve the problem of temperature rise, ensure load demand, and ensure safety and comfort. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

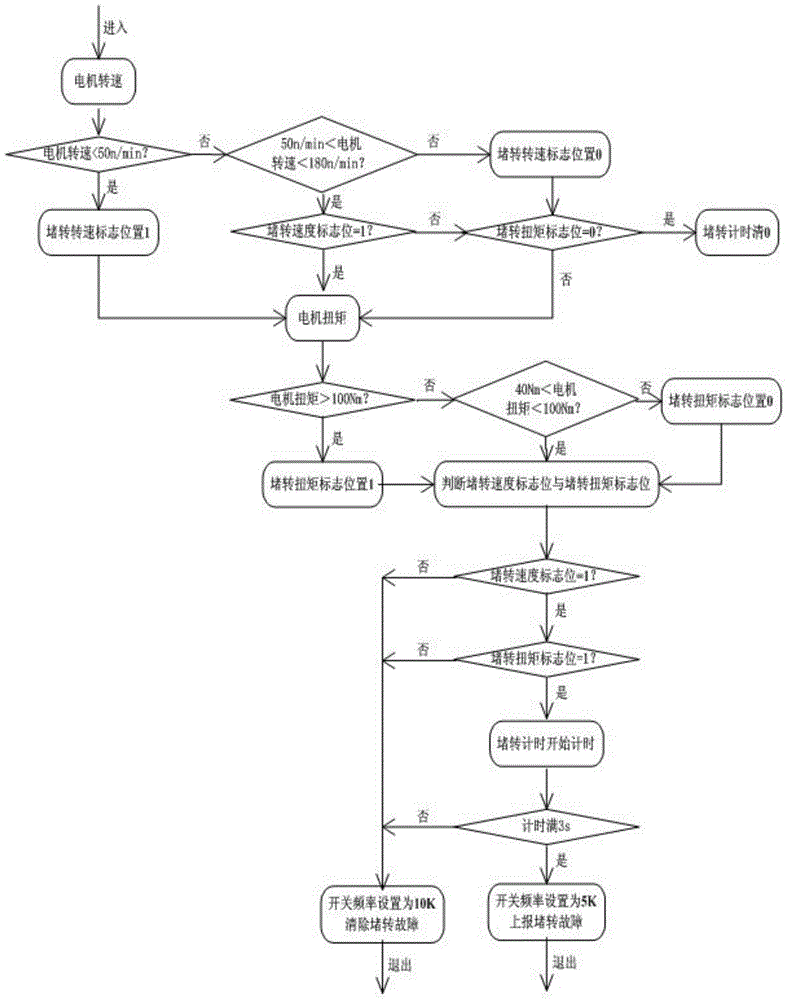

[0052] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

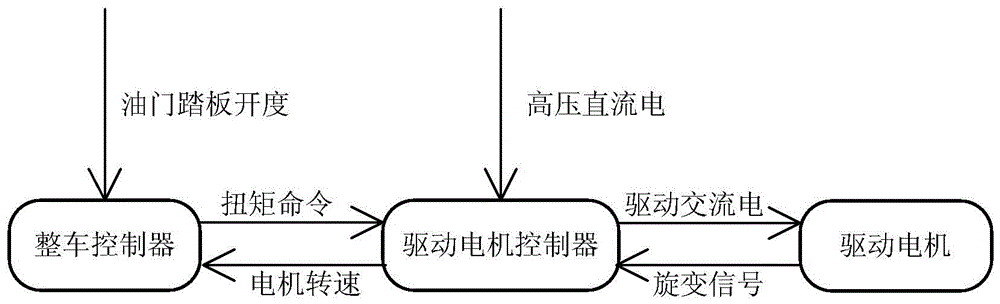

[0053] The working principle of the drive system of electric vehicles can be briefly as follows: figure 1As shown, the vehicle controller sets the torque according to the accelerator pedal opening and the motor speed signal. After the drive motor controller receives the torque command, it controls the drive motor to output the corresponding torque when the drive system is not faulty. The first step is to obtain a set of Id and Iq by looking up the torque value at the current rotational speed (the relationship table between motor torque and current), and then through the space vector algorithm, the controller U, V, W three-phase current.

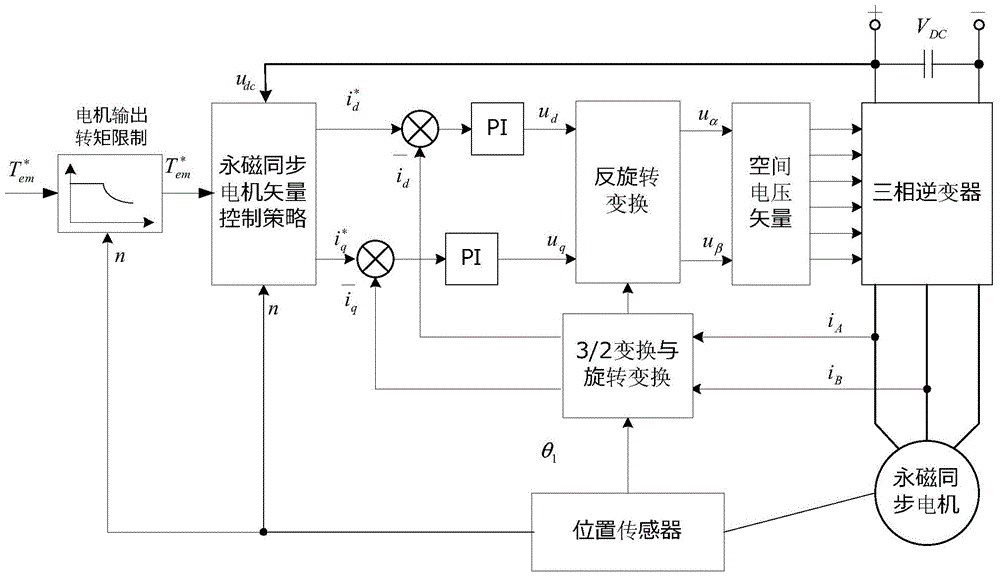

[0054] figure 2 Basic block diagram of vector control for drive motor controller. Firstly, the drive motor controller obtains the torque value that the motor can actually send out according to the torque rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com