Full-automatic drink filling machine

A fully automatic and filling machine technology, applied in the field of mechanical devices, can solve the problems of speed influence, unsuitable for small batch personalized instant production needs, high labor cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

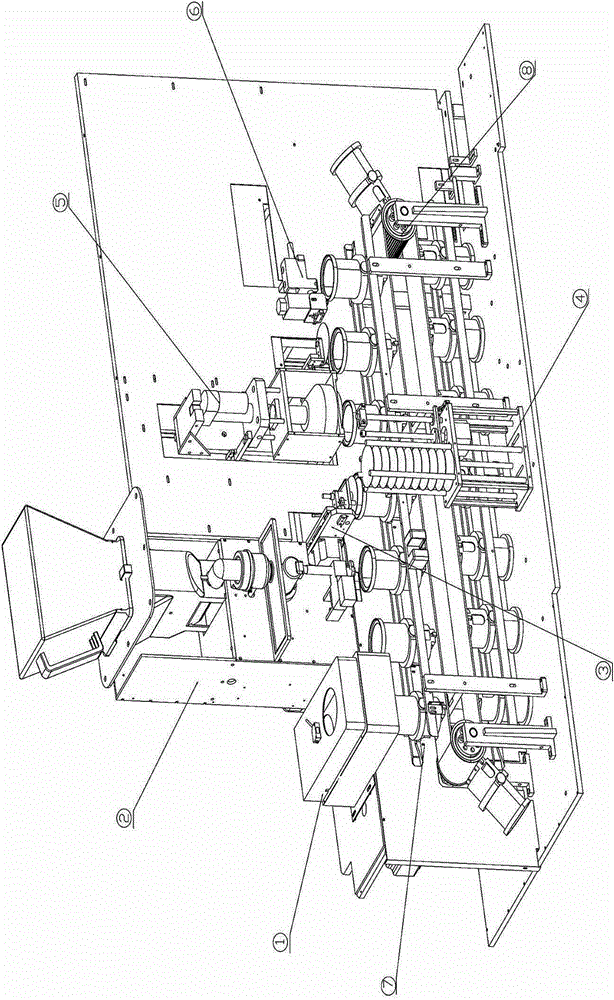

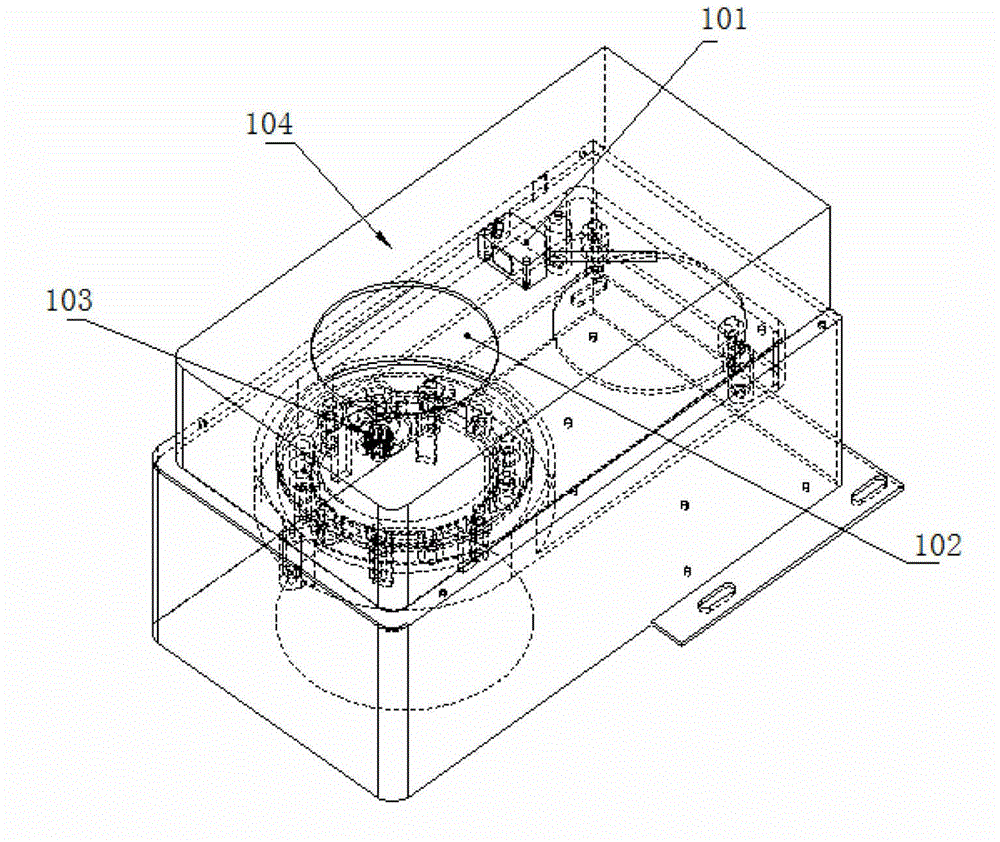

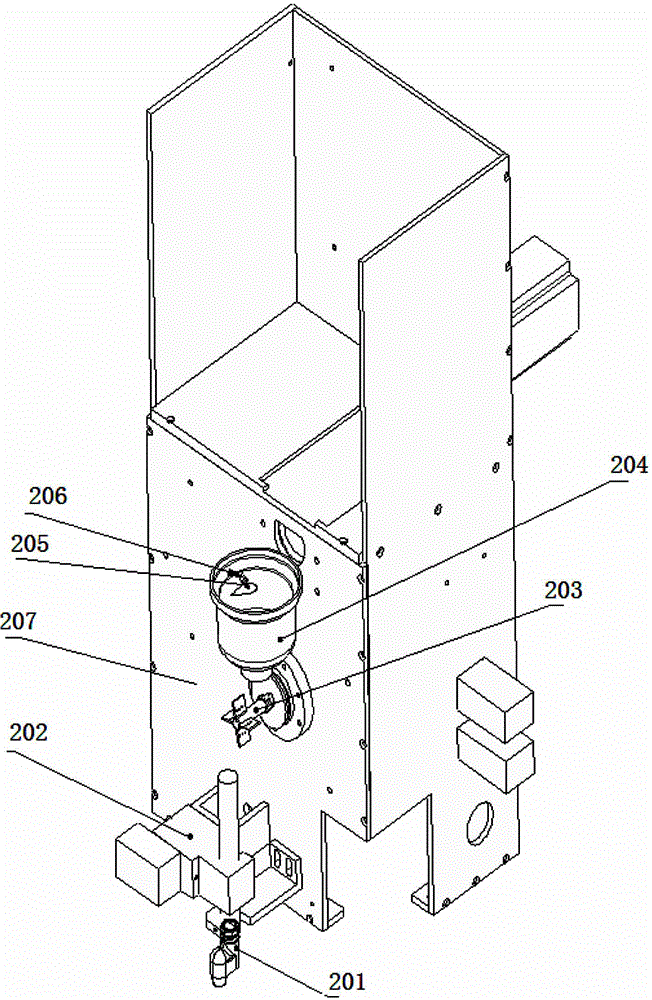

[0026] Such as figure 1 As shown, a fully automatic beverage filling machine includes a cup drop device 1, a fully automatic beverage mixing and filling device 2, a pick-up manipulator device, a fully automatic beverage cup sealing device 5, a coding device 6, a conveying device 8 and a PLC The controller, the cup drop device 1 places the cups one by one on the conveying device 8, driven by the conveying device 8, the cups are filled with beverages through the automatic beverage mixing and filling device 2 in turn, and the cup picking device places the cup cover, and the whole The automatic beverage cup sealing device 5 seals the cup cover, and the coding device 6 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com