Silicone oil paper rewinding machine and application method thereof

A technology of silicone oil paper and rewinding machine, which is applied in the direction of winding strips, sending objects, thin material processing, etc., can solve the problems of low stability, low efficiency and low efficiency of manual operation, and achieves easy processing and high efficiency. , The effect of high rewinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

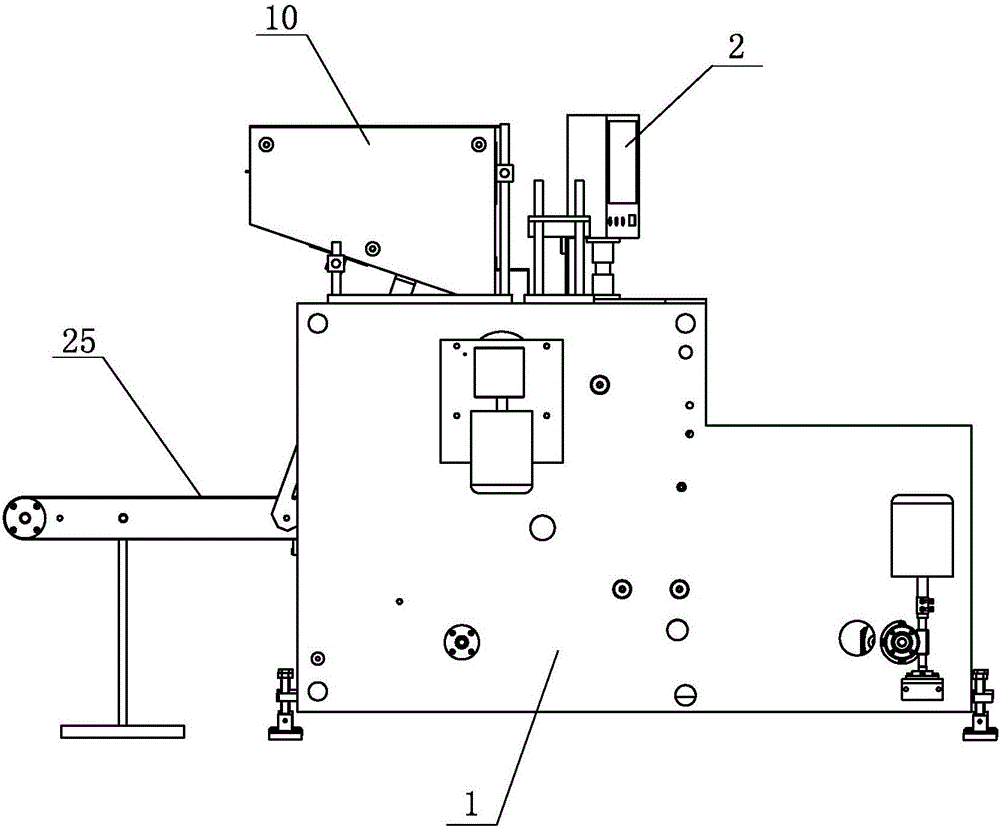

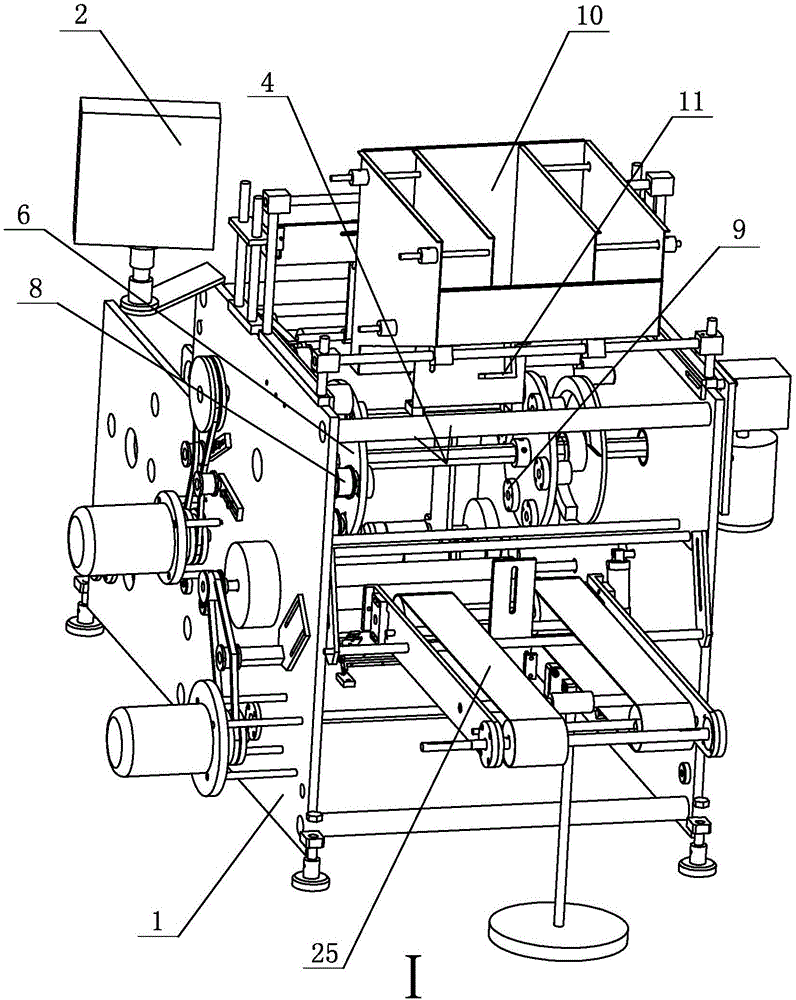

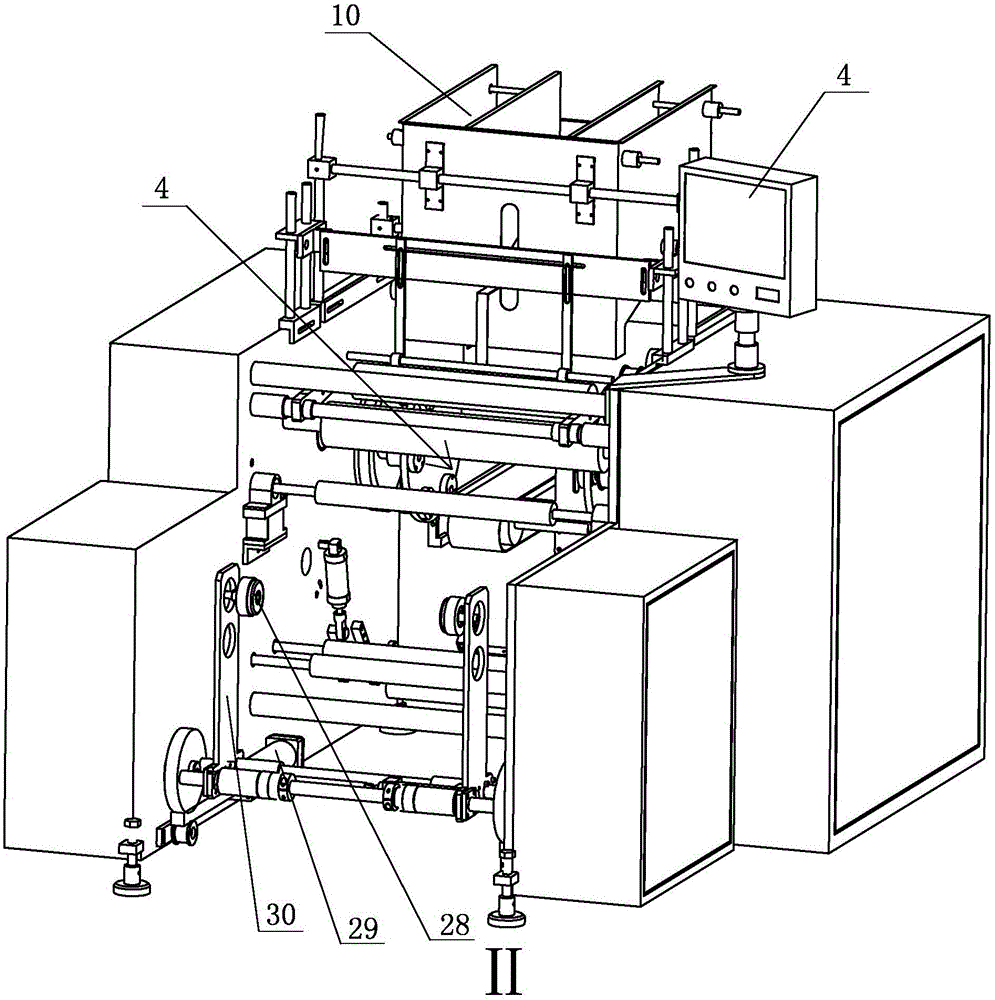

[0040] Embodiment one: see Figure 1~6 As shown, a silicone oil paper rewinding machine includes a frame 1, a rewinding mechanism arranged on the frame 1, an unwinding mechanism, a conveying mechanism and a PLC controller 2,

[0041] The unwinding mechanism, the rewinding mechanism and the conveying mechanism are connected to the PLC controller 2, the unwinding mechanism and the conveying mechanism are respectively arranged at both ends of the frame 1, and the rewinding mechanism is arranged on the Between the unwinding mechanism and the conveying mechanism;

[0042] The rewind mechanism includes a main drum 3 and a multi-station rewind drum 4, the main drum 3 is connected to a motor, the multi-station rewind drum 4 is connected to a stepping motor, and the multi-station The rewinding drum 4 is arranged directly above the tail of the conveying mechanism;

[0043] The multi-station rewinding drum 4 is provided with a plurality of paper tubes 5, and the silicone oil paper to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com