High-efficiency energy-saving emission-reducing combustion improver for fire coal and application method thereof

A combustion-supporting agent, coal-burning technology, applied in the fuel, solid fuel, petroleum industry and other directions, can solve the problems of nitrogen oxides and the absolute content of excess air, etc., to speed up the burnout rate of coal, increase the calorific value of combustion, and improve the The effect of oxidation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

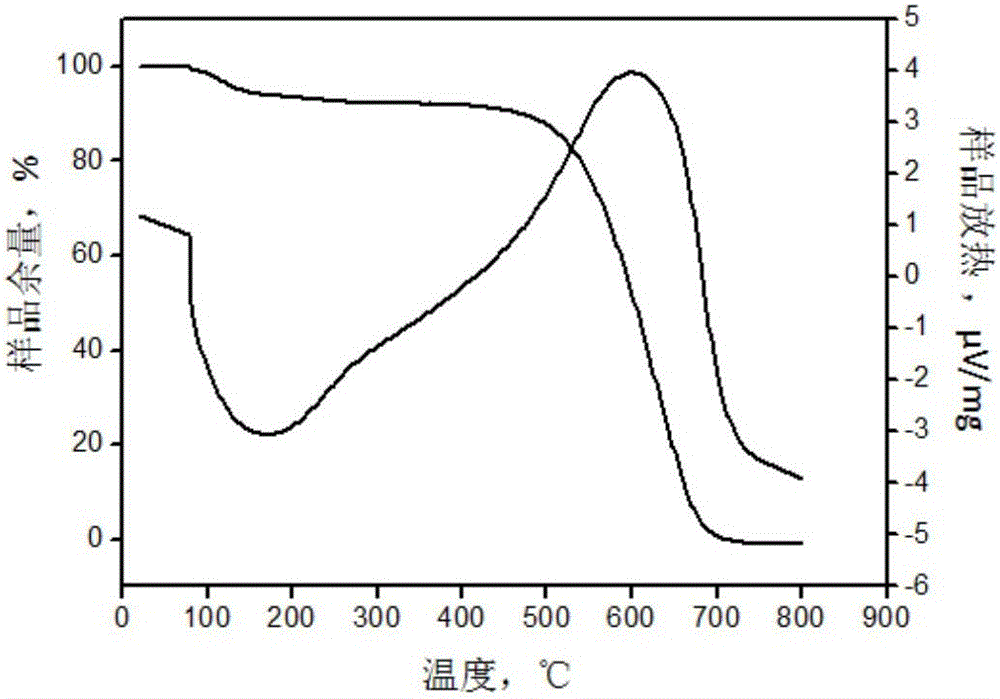

Embodiment 1

[0025] Embodiment 1, the present embodiment provides a kind of specific formula (according to parts by weight) of high-efficiency coal-fired energy-saving and emission-reducing combustion-supporting agent:

[0026]

[0027]

[0028] The above-mentioned materials are crushed, finely ground, and ground into fine powder, then mixed uniformly by a mixer, and then dissolved in water to obtain a high-efficiency coal-burning, energy-saving, emission-reducing combustion accelerant.

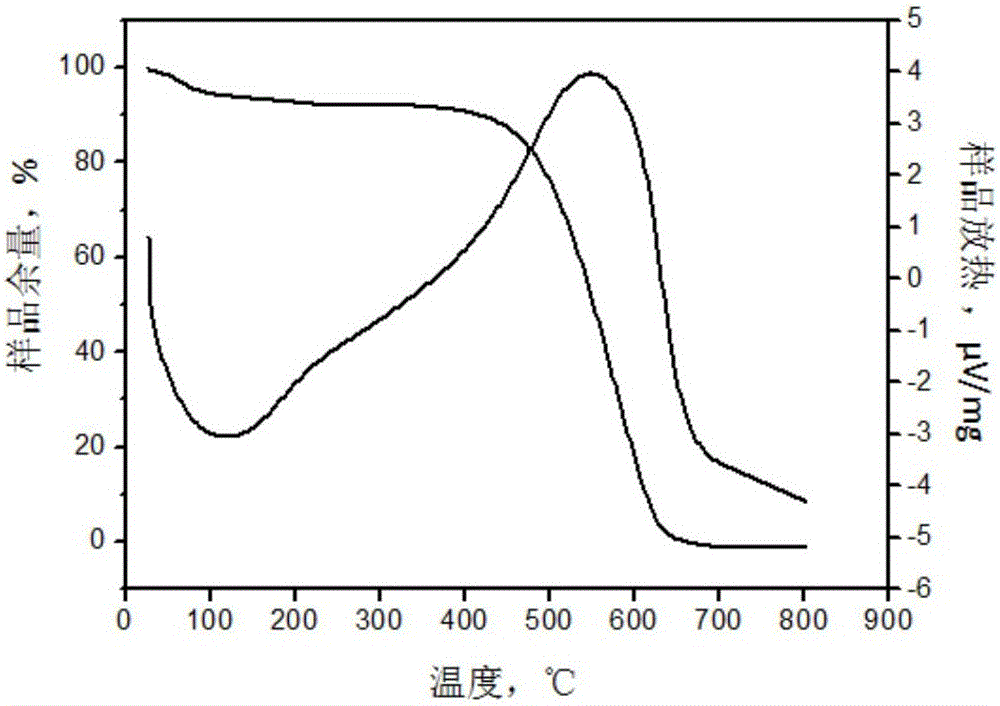

Embodiment 2

[0029] Embodiment 2, the present embodiment provides a specific formula (according to parts by weight) of a high-efficiency coal-fired energy-saving emission-reducing combustion-supporting agent:

[0030]

[0031] The above-mentioned materials are crushed, finely ground, and ground into fine powder, then mixed uniformly by a mixer, and then dissolved in water to obtain a high-efficiency coal-burning, energy-saving, emission-reducing combustion accelerant.

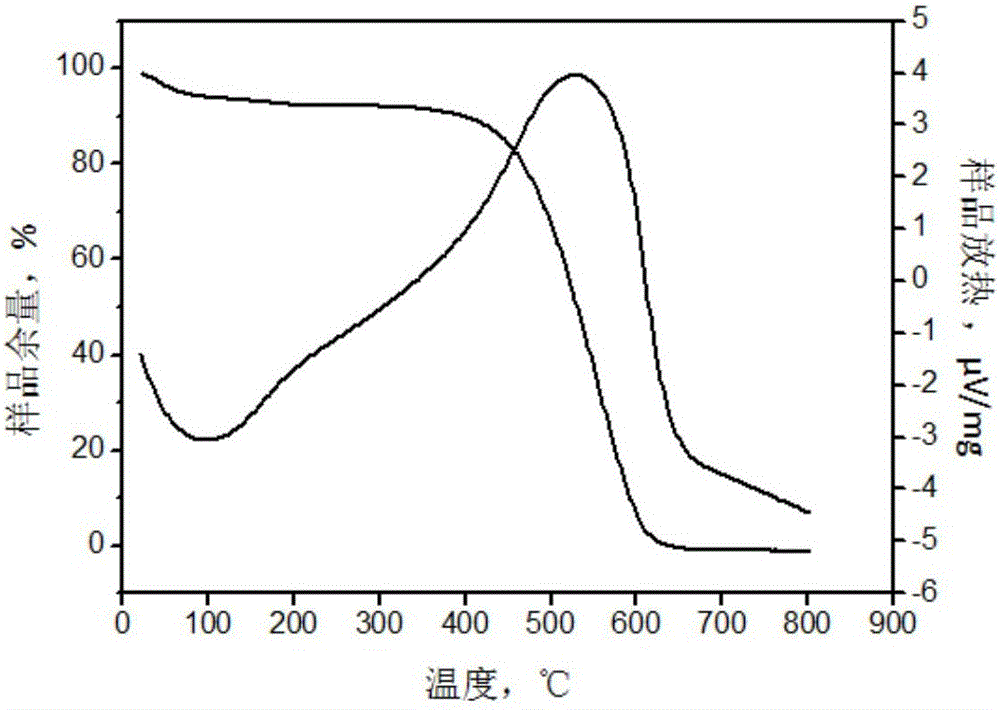

Embodiment 3

[0032] Embodiment 3, the present embodiment provides a specific formula (according to parts by weight) of a high-efficiency coal-burning, energy-saving and emission-reducing combustion-supporting agent:

[0033]

[0034] The above-mentioned materials are crushed, finely ground, and ground into fine powder, then mixed uniformly by a mixer, and then dissolved in water to obtain a high-efficiency coal-burning, energy-saving, emission-reducing combustion accelerant.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap