A manufacturing method for eliminating Lüders bands on the surface of 5754 aluminum alloy plate

A manufacturing method and technology for aluminum alloy plates, applied in the field of automobile aluminum alloy plate manufacturing, can solve the problems of surface wrinkling, yield point elongation, and hand feeling, and achieve the effects of improving strength, improving surface quality and stable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The invention is a manufacturing method for eliminating Lüders bands on the surface of 5754 aluminum alloy plate. The manufacturing steps are: melting and casting---sawing---homogenizing annealing---milling---heating---heating Rolling---cold rolling---finished product annealing---small reduction cold rolling---finishing---packing;

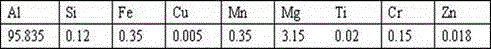

[0055] (1) Melting and casting: In the melting and casting step, the mass percentage of the chemical composition of the ingot after melting and casting is

[0056]

[0057] Among them: the melting temperature is 730-740°C, the refining temperature is 720-730°C, and the casting temperature is 670-685°C;

[0058](2) Homogenization annealing: heat preservation at 550°C for 10 hours;

[0059] (3) Heating: the ingot is heated to 500°C and then kept for 2 hours;

[0060] (4) Hot rolling: the thickness of the hot-rolled billet is 6.5mm, and the final rolling temperature is 315°C;

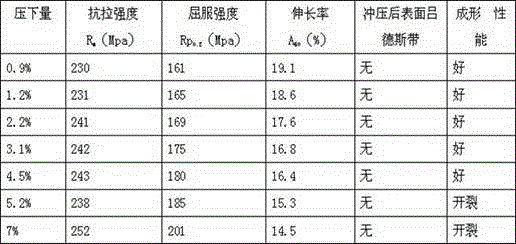

[0061] (5) Cold rolling: After 4 passes of cold rolling to 1m...

Embodiment 2

[0069] The invention is a manufacturing method for eliminating Lüders bands on the surface of 5754 aluminum alloy plate. The manufacturing steps are: melting and casting---sawing---homogenizing annealing---milling---heating---heating Rolling---cold rolling---finished product annealing---small reduction cold rolling---finishing---packing;

[0070] (1) Melting and casting: In the melting and casting step, the mass percentage of the chemical composition of the ingot after melting and casting is

[0071]

[0072] Among them: the melting temperature is 735-740°C, the refining temperature is 725-730°C, and the casting temperature is 680-685°C;

[0073] (2) Homogenization annealing: heat preservation at 580°C for 10 hours;

[0074] (3) Heating: the ingot is heated to 500°C and then kept for 2 hours;

[0075] (4) Hot rolling: the thickness of the hot-rolled billet is 6.5mm, and the final rolling temperature is 305°C;

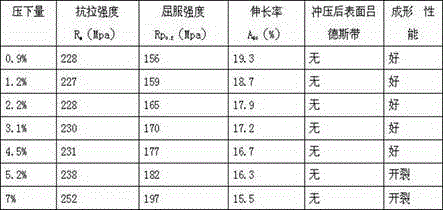

[0076] (5) Cold rolling: After 4 passes of cold rolling to 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com