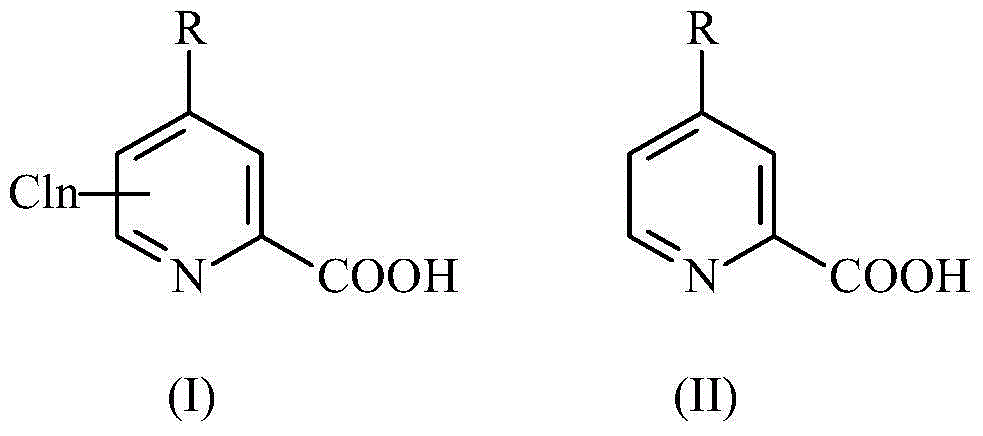

Method for preparing picolinic acid through electro-catalysis selective dechloridation of chloropicolinicacid

A technology of chloropicolinic acid and chloropicolinic acid, which is applied in the field of electrocatalytic selective dechlorination of chloropicolinic acid, can solve the problems of poor dechlorination selectivity, incomplete dechlorination, toxic reducing agents and toxic electrode materials, etc. Achieve high chemical selectivity and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

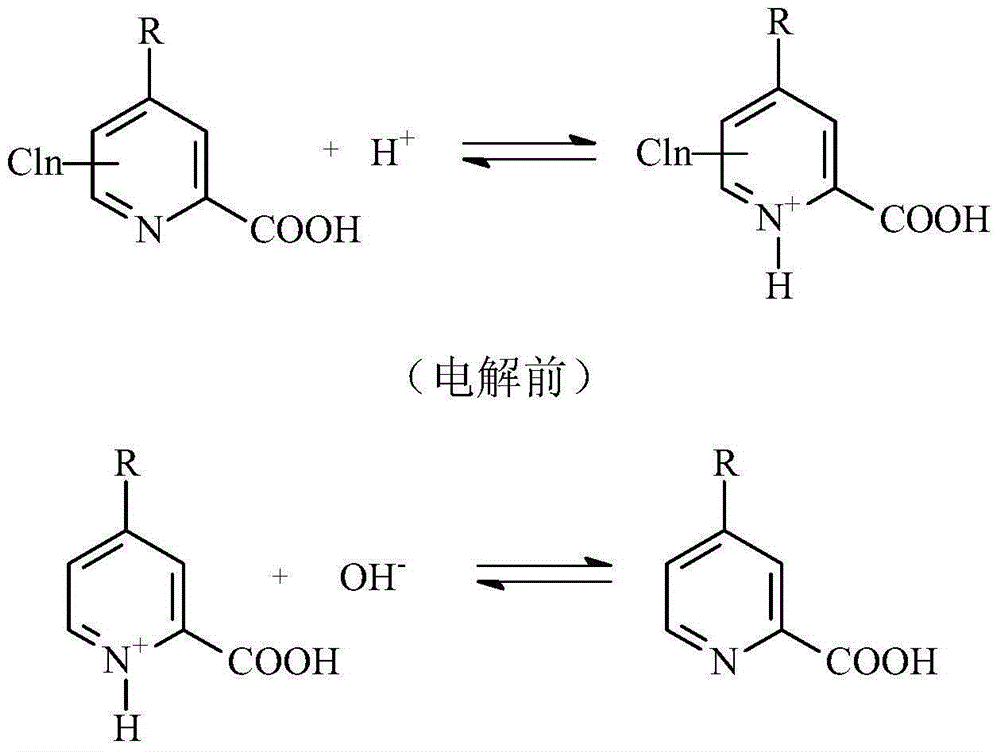

[0035] Embodiment 1 electrolysis of 3,6-dichloropicolinic acid (3,6-D) to synthesize picolinic acid (PA)

[0036] Diaphragm plate frame tank is the electrolytic reactor, the perfluorosulfonic acid membrane is the diaphragm, and the expanded screen palladium-modified silver is the cathode (1g pd / m 2 ), the platinum-plated titanium mesh is the anode. 1000mL 1mol / L sulfuric acid + 20% methanol + 100g 3,6-D aqueous solution is catholyte; 1mol / L sulfuric acid aqueous solution is anolyte. During the electrolysis process, the temperature is controlled at 20-25°C, and the current density is controlled at 3A / dm 2 , catholyte pH=0~0.5, cathode potential is -0.3~-0.6V vs.Ag / AgCl (3.0M KCl). Stop electrolysis after feeding 4F / mol 3,6-D electricity. After the catholyte was transferred to the beaker, sodium hydroxide was added to adjust the pH=4, and then the yield of PA was analyzed by HPLC to be 95%, the selectivity was 95%, and the dechlorination current efficiency was 96%.

[0037] ...

Embodiment 2

[0040] Example 2 Electrolysis of 3,5,6-trichloropicolinic acid, 3,6-D, 3,5-dichloropicolinic acid, 3-chloropicolinic acid, 6-chloropicolinic acid mixture to synthesize PA

[0041] Diaphragm plate frame tank is the electrolytic reactor, the perfluorosulfonic acid membrane is the diaphragm, and the expanded screen palladium-modified silver is the cathode (1g pd / m 2 ), the platinum-plated titanium mesh is the anode. 1000mL 1mol / L sulfuric acid+40%methanol+2.26g 3,5,6-trichloropicolinic acid+95.0g 3,6-D+1.16g 3,5-dichloropicolinic acid+1.1g 3-chloropicolinic acid+ The aqueous solution of 0.48 gram of 6-chloropicolinic acid is catholyte; 1mol / L sulfuric acid aqueous solution is anolyte. During the electrolysis process, the temperature is controlled at 35-40°C, and the current density is controlled at 5A / dm 2 , catholyte pH=0~0.5, cathode potential is -0.3~-0.7V vs. Ag / AgCl (3.0M KCl). Stop electrolysis after feeding 5F / mol 3,6-D electricity. After the catholyte was transferred ...

Embodiment 3

[0042] Example 3 Electrolysis of 4-amino-3,5,6-trichloropicolinic acid, 4-amino-3,6-dichloropicolinic acid, 4-amino-3,5-dichloropicolinic acid, 4-amino-3 Synthesis of 4-aminopicolinic acid from a mixture of -chloropicolinic acid and 4-amino-6-chloropicolinic acid

[0043] Diaphragm plate frame tank is the electrolytic reactor, the perfluorosulfonic acid membrane is the diaphragm, and the expanded screen palladium-modified silver is the cathode (1g pd / m 2 ), the platinum-plated titanium mesh is the anode. 1000mL 1mol / L sulfuric acid + 20% methanol + 2.42 grams of 4-amino-3,5,6-trichloropicolinic acid + 95.0 grams of 4-amino-3,6-dichloropicolinic acid + 0.84 grams of 4-amino-3, The aqueous solution of 5-dichloropicolinic acid+1.5 g of 4-amino-3-chloropicolinic acid+0.24 g of 4-amino-6-chloropicolinic acid is the catholyte; the aqueous solution of 1mol / L sulfuric acid is the anolyte. During the electrolysis process, the temperature is controlled at 25-35°C, and the current dens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com