A staged toilet flushing method

A staged, toilet technology, applied in the field of sanitary ware, can solve the problems of unstable cleaning effect of toilet pool dirt receiving surface, spray flushing effect, inconsistent water volume, shortened siphon time, etc., to achieve stable spray effect and maintenance Continue and promote the effect of siphon generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

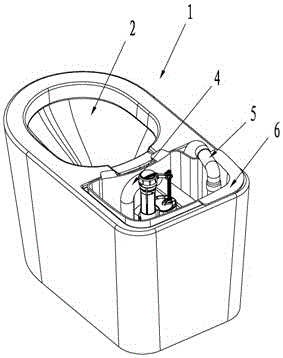

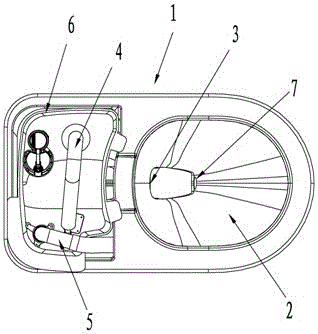

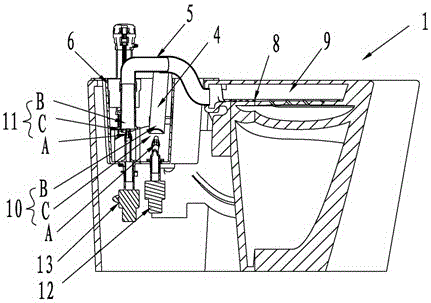

[0025] Embodiment 1: (the toilet flushing device includes a water tank and two pump devices, and the water supply source of the flushing water pipeline and the flushing water pipeline includes the water in the water tank)

[0026] Such as Figure 1-3 As shown, in order to solve the technical problems in the background technology, the present invention provides a staged toilet flushing method, which controls the flushing water and flushing water respectively, including the following steps: S1, turning on the flushing water , wash the dirt receiving surface of the toilet pool, turn off the washing water after the predetermined time period T1 is turned on for the washing water; S2, turn on the flushing water, flush the spray hole at the bottom of the toilet pool to make the toilet waste discharge pipe form a siphon; S3. After the flushing water is turned on for a predetermined time period T2, the flushing water is turned on again. The flushing water first washes the dirt receivin...

Embodiment 2

[0037] Embodiment 2: (the toilet flushing device does not include a water tank, but includes a control valve, and the water supply source of the two pipelines of washing water and flushing water is the water in the water supply pipe network)

[0038] In order to solve the technical problems in the background technology, the present invention provides a step-by-step toilet flushing method, which controls the flushing water and flushing water respectively, including the following steps: S1, turning on the flushing water, flushing the toilet Wash the dirt receiving surface of the pool, and turn off the washing water after opening the predetermined time period T1 of the washing water; S2, turn on the flushing water, and flush the spray holes at the bottom of the toilet pool to form a siphon for the toilet waste discharge pipe; S3, in the After the flushing water is turned on for a predetermined time period T2, the flushing water is turned on again. The flushing water first washes t...

Embodiment 3

[0043] Embodiment 3: (the toilet flushing device does not include a water tank, but includes two control valves, and the water supply source of the two pipelines of flushing water and flushing water is the water in the water supply pipe network)

[0044] In order to solve the technical problems in the background technology, the present invention provides a step-by-step toilet flushing method, which controls the flushing water and flushing water respectively, including the following steps: S1, turning on the flushing water, flushing the toilet Wash the dirt receiving surface of the pool, and turn off the washing water after opening the predetermined time period T1 of the washing water; S2, turn on the flushing water, and flush the spray holes at the bottom of the toilet pool to form a siphon for the toilet waste discharge pipe; S3, in the After the flushing water is turned on for a predetermined time period T2, the flushing water is turned on again. The flushing water first wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com