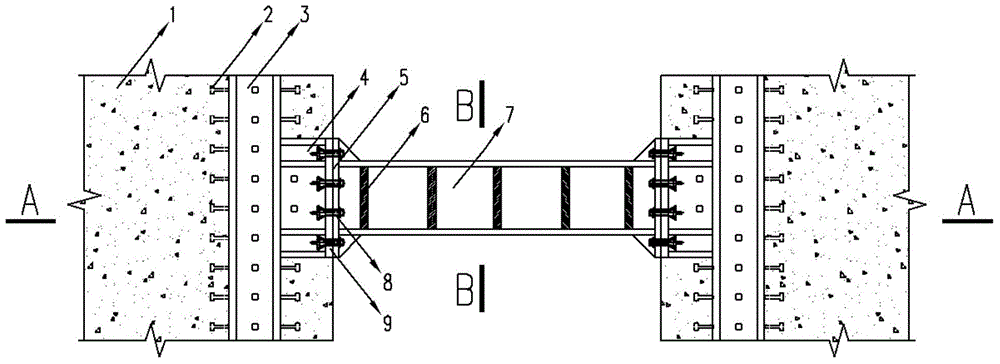

High-accuracy steel connecting beam and concrete shear wall assembling type single-way bolt connecting system

A concrete shear wall and one-way bolt technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of component installation and positioning, component axial and lateral errors, etc. Avoid time-consuming effects of welding construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

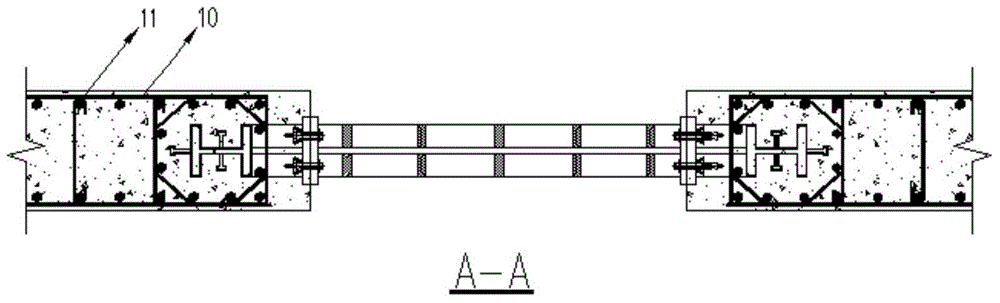

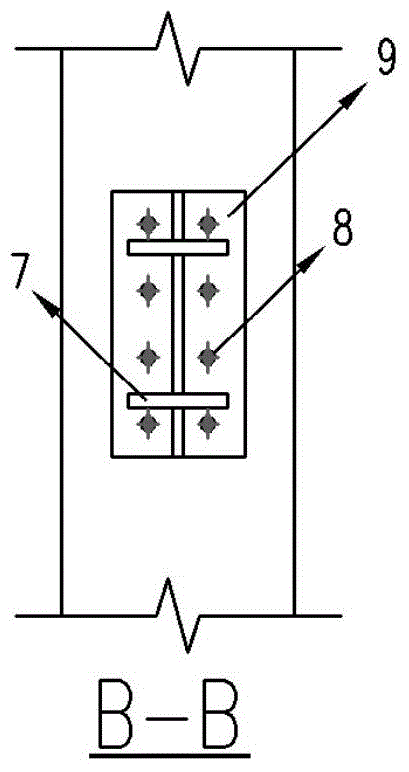

[0042] A continuous steel frame column is set in the hidden column area at the inner end of the concrete shear wall, and the steel frame column is welded to the corbel steel beam section at the position where the steel connecting beam is set. In order to facilitate the construction of the shear wall, the corbel must be completely buried in the concrete , the outer surface of the end plate welded with the corbel is flush with the outer surface of the concrete shear wall, and the position of the one-way bolt is reserved with foam, and the end of the beam needs to be welded with the end plate. The web area at the end of the corbel is reserved to set a reserved circular stirrup hole (the diameter of the hole is 5mm larger than the diameter of the stirrup in the concealed column of the concrete wall), so as to facilitate the binding of the stirrup in the concealed column area during on-site construction. The steel structure processing plant completes the steel component fabrication ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com