Power plant boiler high-temperature pipe system macro displacement measurement device and method based on CCD photography

A technology for displacement measurement and power station boilers, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of inability of remote transmission of measurement data, long cycle, safety monitoring data sorting and analysis, and information feedback lag, etc., to achieve synchronization Good, short-cycle, real-time monitoring and evaluation of the effectiveness of security conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

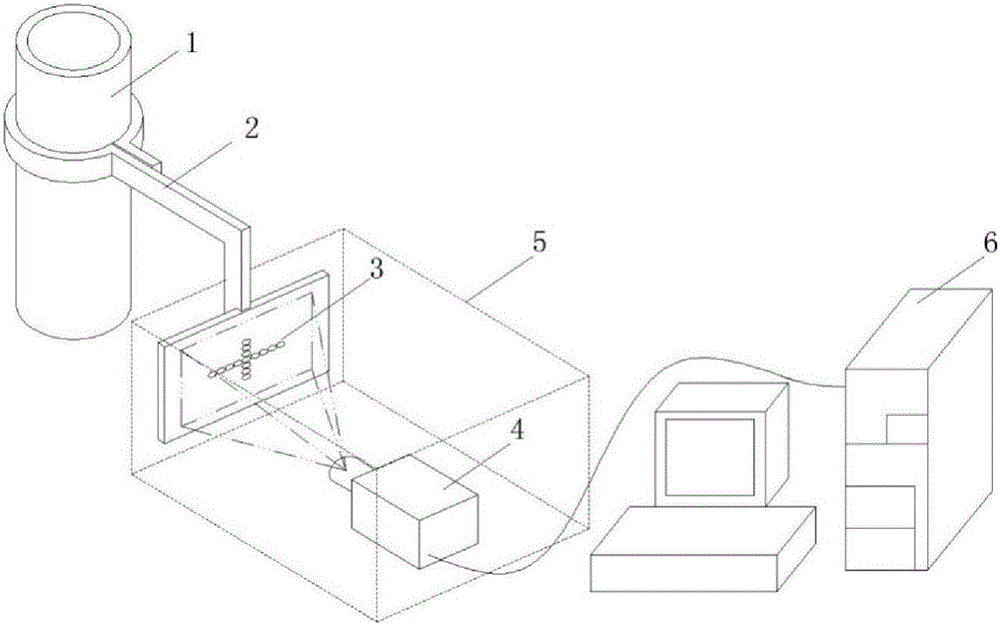

[0040] Such as figure 1 As shown, the embodiment of the high-temperature pipe system macroscopic displacement measurement device based on CCD photography of the present invention includes: fixed assembly 2, cross-shaped LED lamp group 3, CCD camera 4, metal cover 5, image processor 6, 1 is high temperature Piping system to be tested.

[0041] The hoop of the fixing component 2 is fastened to the pipe to be tested in the high-temperature piping system. One end of the rod-shaped bracket is fixed on the hoop, and a flat plate is fixed on the other end of the rod-shaped bracket. The hoop is connected to the flat plate through the bracket. The cross-shaped LED lamp group 3 composed of LED lamps formed by a cross-line array is installed in the center of the panel, and the CCD camera 4 corresponds to the cross-shaped LED lamp group 3, and is connected to the image processor 6 through a signal cable, and the panel and the camera of the fixed component are placed In the metal cover 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com