Anti-interference ultrasonic probe

A technology of ultrasonic and piezoelectric wafers, which is applied in the field of ultrasonic probes, can solve the problems of increasing energy loss, affecting measurement accuracy, and affecting resolution, etc., and achieves the effects of reducing pulse width, absorbing clutter, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

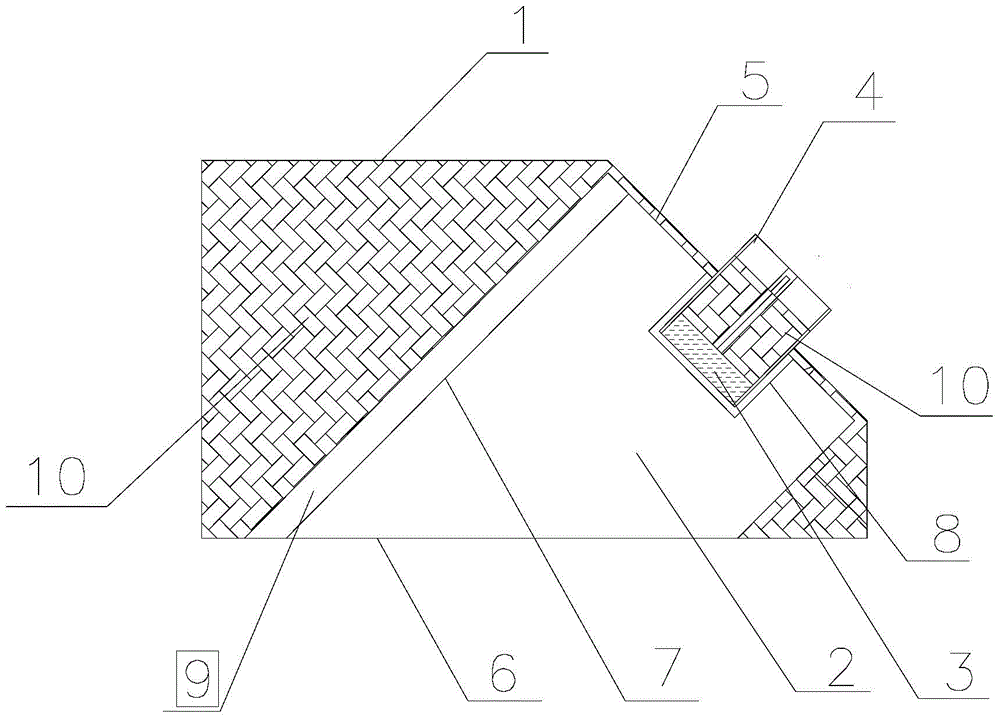

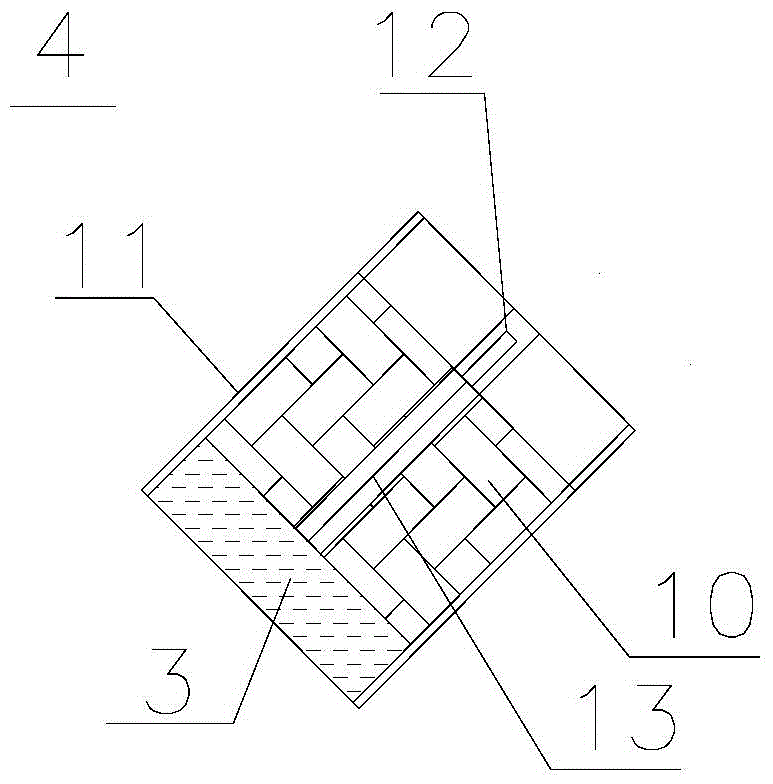

[0018] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

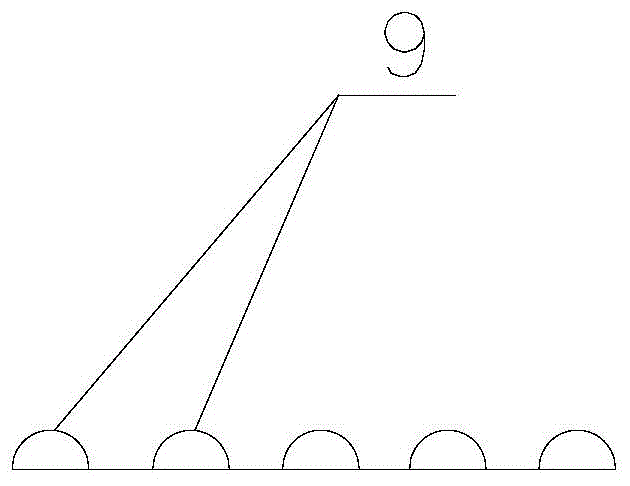

[0019] Such as Figure 1-4 As shown, a kind of anti-interference ultrasonic probe of the present invention comprises housing 1, wedge 2, piezoelectric chip 3 and probe interface 4, and wedge 2 is placed in housing 1, and wedge 2 is provided with end face 5, The wedge-shaped surface 6 and the connection surface 7 connected between the end surface 5 and the wedge-shaped surface 6, the end surface 5 is provided with a groove 8, the connection end of the probe interface 4 and the piezoelectric wafer 3 is arranged in the groove 8, the probe interface 4 and the pressure The opposite end of the electric chip 3 extends out of the housing, and the connection surface 7 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com