Locking Cage Mounts

A mounting frame and locking technology, which is applied in the field of optical components, can solve the problems that the connecting rod affects the coaxiality of the optical path, affects the next assembly of the connecting rod, and is easy to scratch the connecting rod, etc., so as to achieve the effect of easy locking and locking Good, avoid scratch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

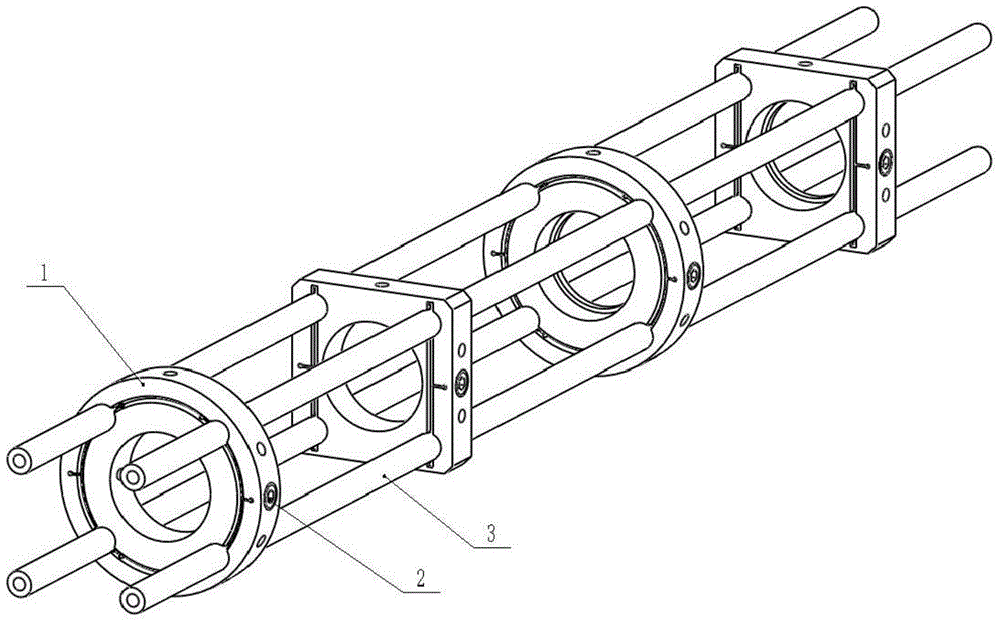

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereto.

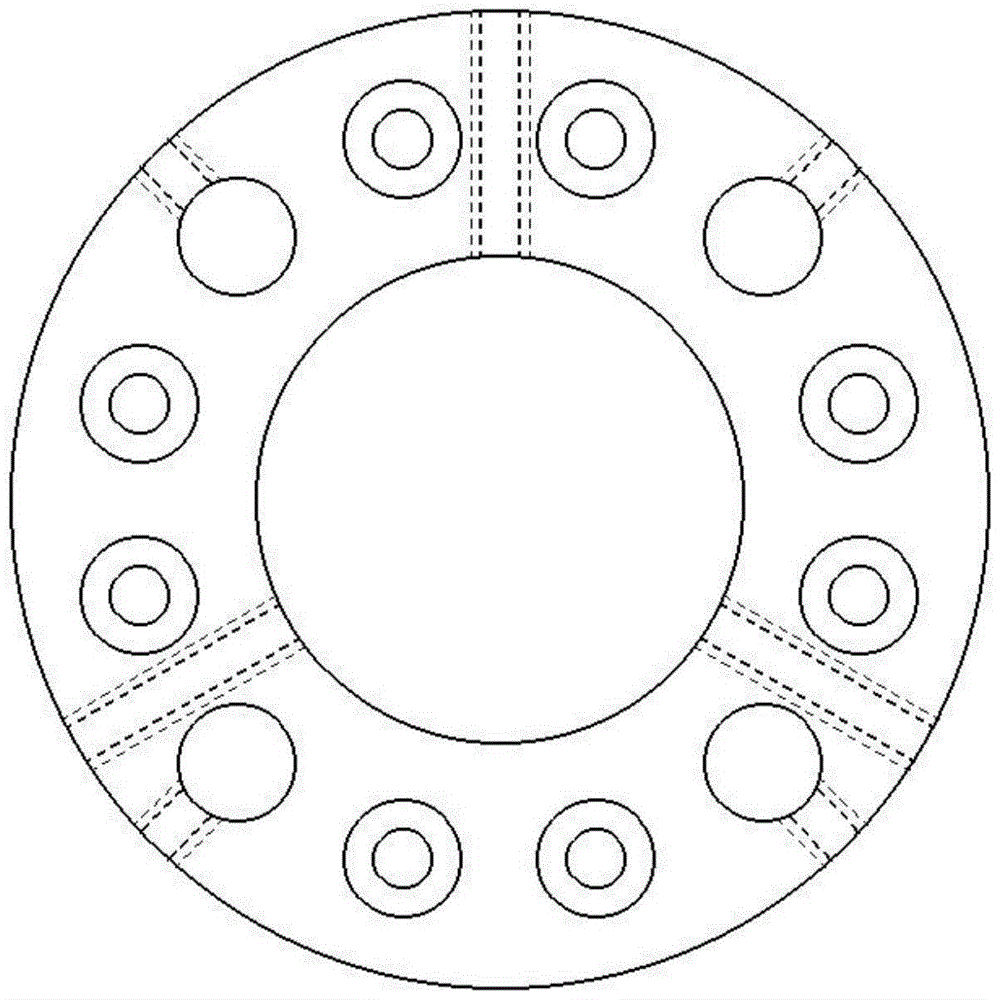

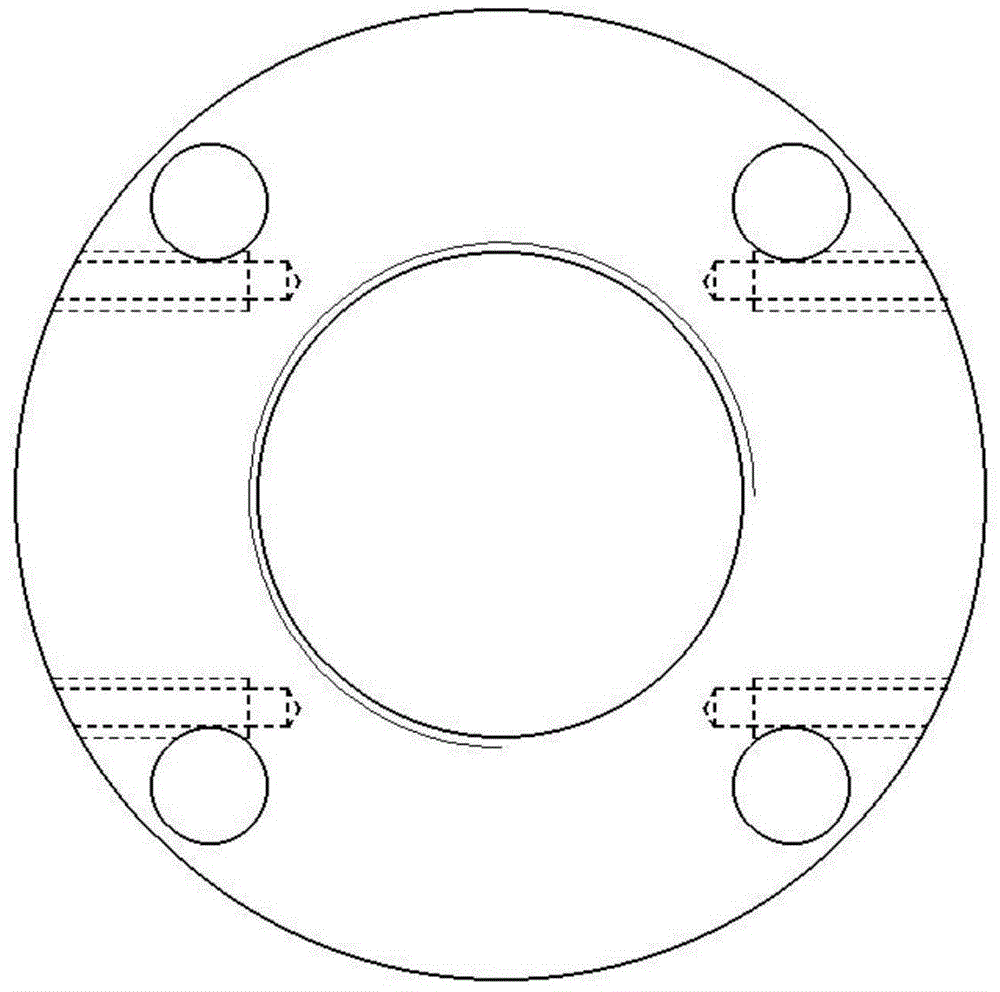

[0028] see first image 3 , and see in conjunction with Figure 4 , 5 , 6, 7, 8, 9, 10, 11, as can be seen from the figure, the locking cage mounting frame of the present invention includes: a plurality of cage plates 1, a plurality of screws 2, and four connecting rods 3.

[0029] The cage plate 1 has a central hole 101 and four connecting rod through holes 102 evenly distributed around it, and the axes of the four connecting rod through holes 102 are parallel to the central axis of the central hole 101. The two connecting rod through holes 102 on both lateral sides of the cage plate 1 are connected through a through groove 103, and the connection between the connecting rod through holes 102 and the through groove 103 has a first semicircular opening 109, and the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com