Data monitoring method and system used for boiling sugar crystallization process

A data monitoring and crystallization technology, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problem that some parameters that cannot be boiled and crystallized cannot be directly measured, and achieve strong expansion capabilities and openness, and improve stability Sexuality and reliability, the effect of a high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

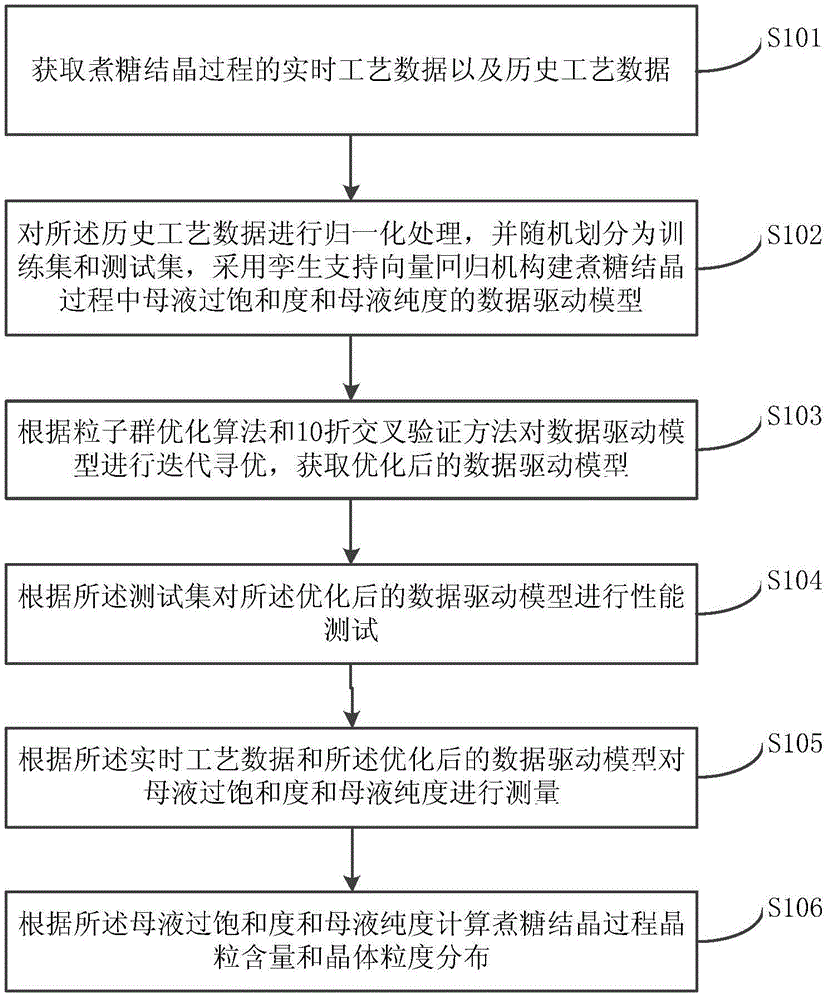

[0066] Such as figure 1 As shown, the method includes:

[0067] Step S101: Obtain real-time process data and historical process data of the sugar boiling and crystallization process;

[0068] Obtaining historical process data is the process of selecting and constructing auxiliary variables of the soft-sensing data-driven model in the process of boiling sugar crystallization. The historical process data is the auxiliary variable, and the auxiliary variables are state parameters directly measured online during the process of boiling sugar crystallization;

[0069] The state parameters directly measured online can include any one or several of the following: vacuum degree, massecuite temperature, liquid level of massecuite, steam pressure, steam temperature, feed flow rate, massecuite hammer.

[0070] Step S102: Perform normalization processing on the historical process data, and randomly divide it into training set and test set, and use Twin Support Vector Regression Machine to...

Embodiment 2

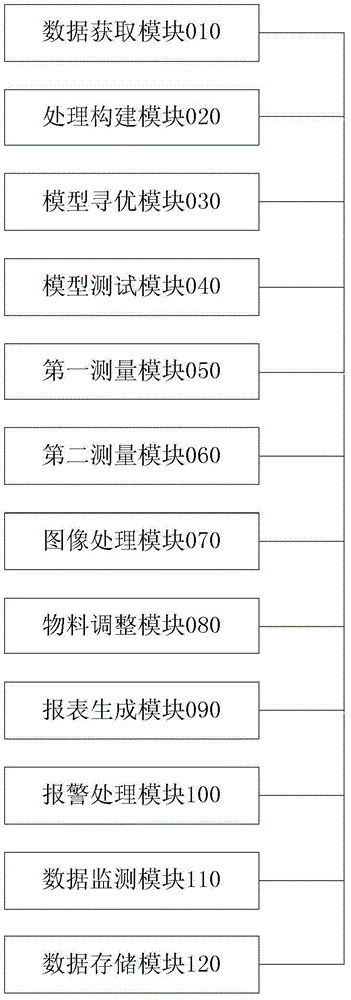

[0137] The present invention also proposes a data monitoring system for boiled sugar crystallization, such as figure 2 shown, including:

[0138] Data acquisition module 010, used to acquire real-time process data and historical process data of the boiling sugar crystallization process;

[0139] The processing building block 020 is used to normalize the historical process data, and randomly divide it into a training set and a test set, and adopt twin support vector regression mechanism to construct the data of mother liquor supersaturation and mother liquor purity in the boiling sugar crystallization process drive model;

[0140] The model optimization module 030 is used to iteratively optimize the data-driven model according to the particle swarm optimization algorithm and the 10-fold cross-validation method, and obtain the optimized data-driven model;

[0141] A model testing module 040, configured to perform a performance test on the optimized data-driven model according...

Embodiment 3

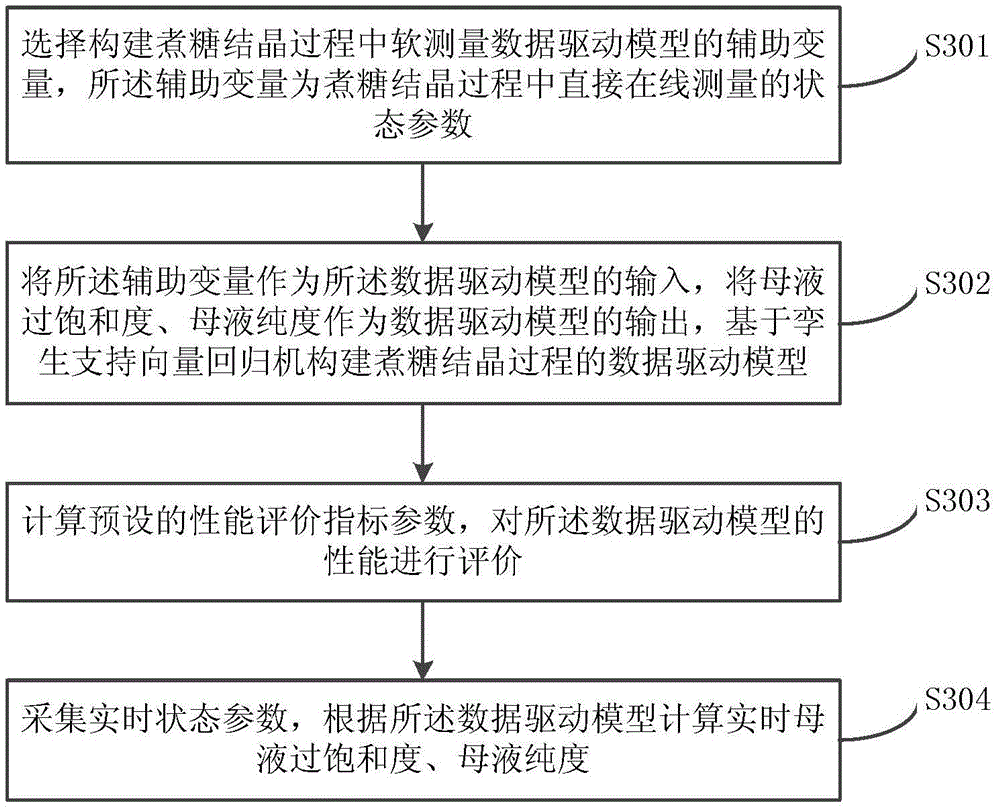

[0157] Such as image 3 Shown, the data measuring method that is used for boiled sugar crystallization of the present invention comprises:

[0158] Step S301: selecting an auxiliary variable for constructing a soft-sensing data-driven model in the process of boiling sugar and crystallization, and the auxiliary variable is a state parameter directly measured online during the process of boiling sugar and crystallization;

[0159] The state parameters directly measured online can include any one or several of the following: vacuum degree, massecuite temperature, liquid level of massecuite, steam pressure, steam temperature, feed flow rate, massecuite hammer.

[0160] Step S302: using the auxiliary variable as the input of the data-driven model, taking the supersaturation degree of mother liquor and the purity of mother liquor as the output of the data-driven model, and constructing a data-driven model of the boiling sugar crystallization process based on twin support vector regr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com