Flexible fireproof cable pre-branching connector and machining and installing method thereof

A fire-proof cable and pre-branching technology, applied in the direction of cable installation, cable installation device, cable joint, etc., can solve the problems of inconvenient replacement, cable slippage, disconnection, etc., and achieve convenient assembly operation, compact structure, and reduced volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

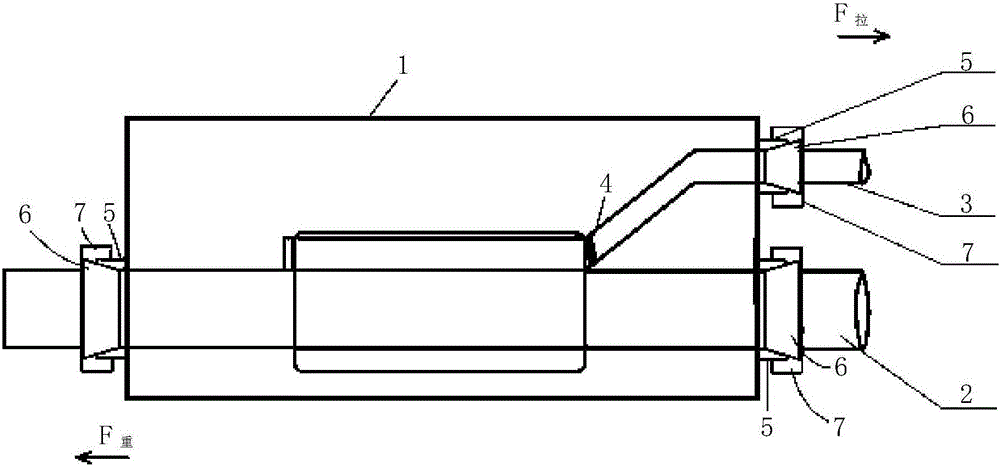

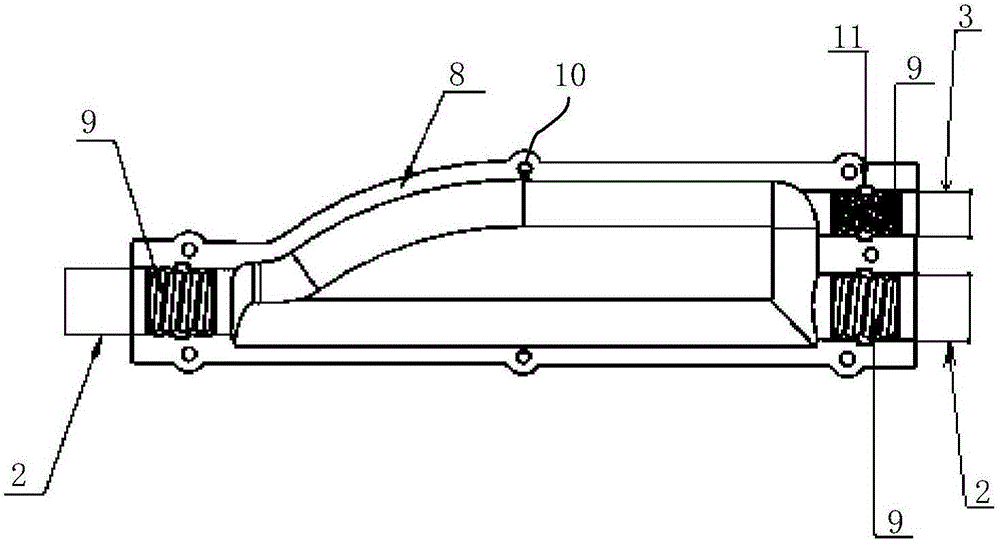

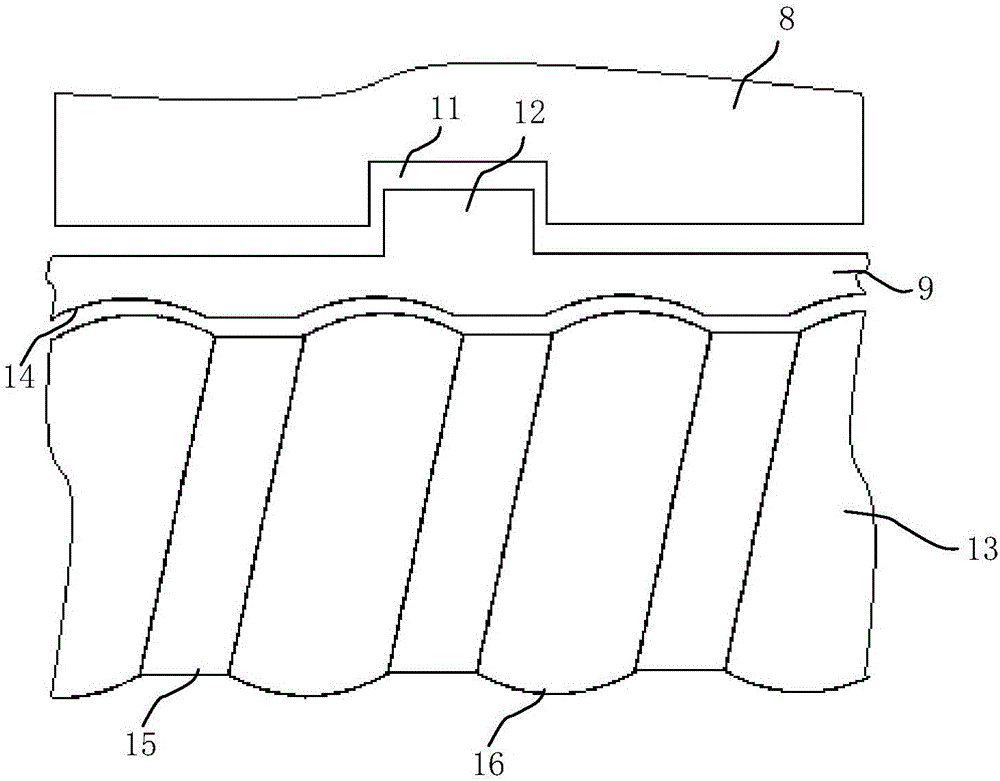

[0026] figure 2 It is a structural schematic diagram of the flexible fireproof cable pre-branch connector of the present invention; image 3 It is a schematic diagram of engagement and fixation of the connector housing, the crimping block and the cable outer sheath of the pre-branch connector of the present invention.

[0027] See figure 2 and image 3 , the flexible fireproof cable pre-branching connector provided by the present invention includes a connector housing 8, wherein the connector housing 8 is spliced by two symmetrical semicircular block housings, and the connector housing 8 One end is the main cable inlet and branch cable inlet, and the other end is the main cable outlet after connection. The main cable inlet, branch cable inlet and main cable outlet are all provided with crimping Block 9, the crimping block 9 is spliced by two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com