Synthetic method and application of PtRu binary metal nano-alloy catalyst

A technology of nano-alloy and binary metal, applied in the field of synthesis of PtRu binary metal nano-alloy catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

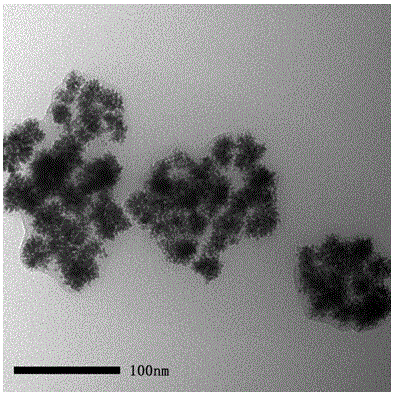

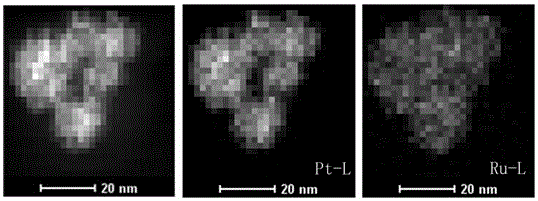

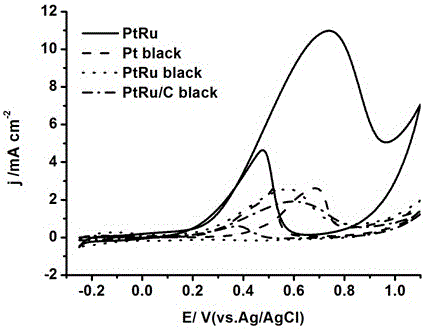

Image

Examples

Embodiment Construction

[0024] Specific implementation 1:

[0025] (1) Add the surfactant and the reducing agent into the aqueous solution at a mass ratio of 2:3, and stir for 15 minutes;

[0026] (2) Add chloroplatinic acid solution and ruthenium trichloride solution with a volume ratio of 3:2 to the mixed solution (5.6mL) in step (1), both at a concentration of 0.1mol / L, and the color of the mixed solution is yellow-brown , stirring at room temperature for 15 minutes;

[0027] (3) Transfer the solution obtained in step (2) into the reactor, react for 2 hours, and control the temperature at about 200°C;

[0028] (4) The obtained product is separated by centrifugation and washed three times with alcohol solution, and then dispersed and stored in alcohol solution, with good dispersibility and general catalytic activity.

[0029] Specific implementation 2:

[0030] (1) Add the surfactant and the reducing agent into the aqueous solution at a mass ratio of 2:3, and stir for 20 minutes;

[0031] (2) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com