Sensitive electrode, formaldehyde flexible sensor and preparation method of sensitive electrode

A flexible sensor and sensitive electrode technology, applied in instruments, scientific instruments, electrochemical variables of materials, etc., can solve the problems of signal stability and selectivity affected by environmental factors, complex structure of infrared sensors, and reduced porosity, etc. The effect of anti-CO poisoning ability, improving catalytic oxidation performance, and improving electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

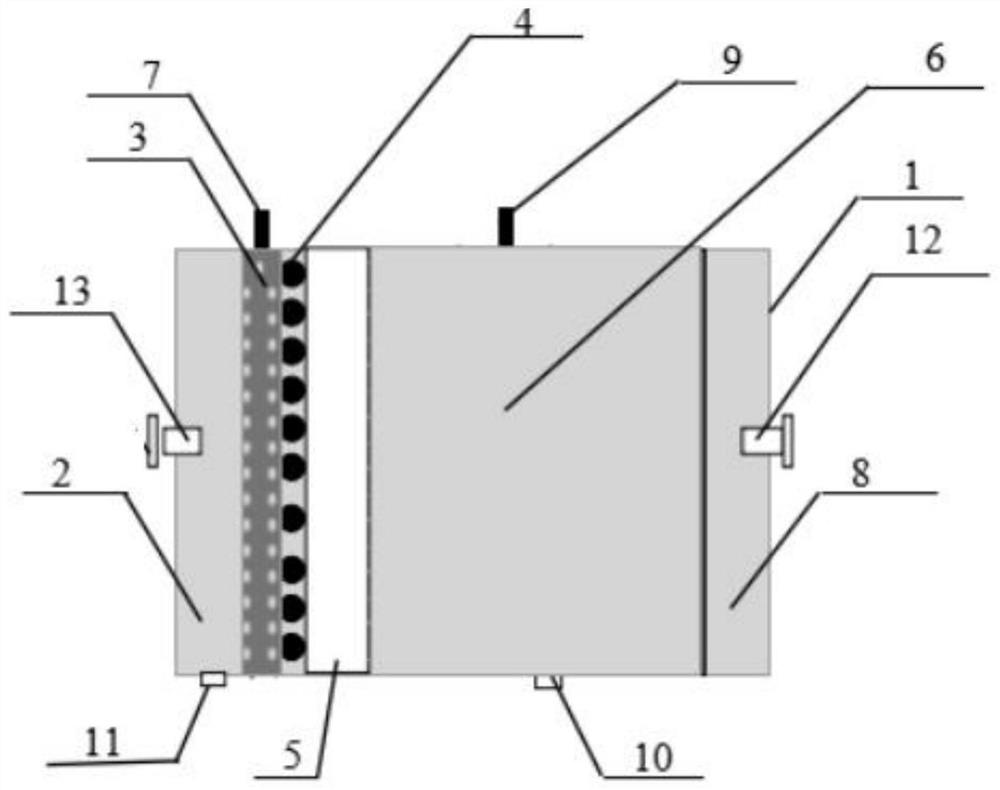

[0027] (1) Pretreatment of titanium foil: ultrasonic degreasing in acetone for 15 minutes, methanol or ethanol cleaning, 1mol / L HF treatment for 10 minutes, double distilled water ultrasonic cleaning for 3 times, and drying;

[0028] (2) Formation of porous titanium foil: soak the cleaned titanium foil in H 2 o 2 Heat to 90°C, continue heating for 40-60min, wait for H 2 o 2 Take out the titanium foil after it turns dark blue, wash it several times with distilled water and absolute ethanol, then dry it, and then place it in a muffle furnace for calcination at 300°C for 30 minutes. After taking it out, a titanium foil with a three-dimensional porous structure is obtained.

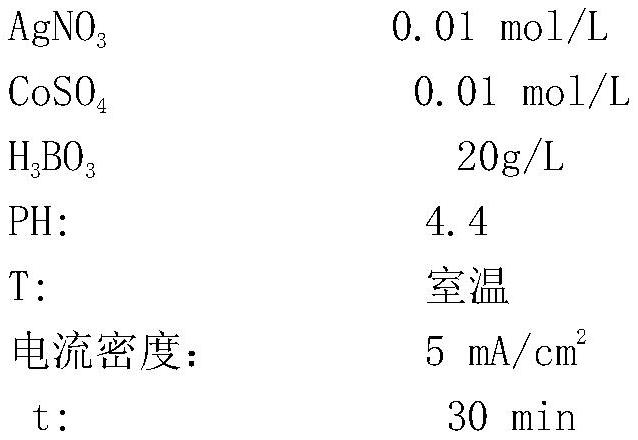

[0029] (3) TiO on the inner and outer surfaces of pores 2 Formation of nanotubes: the treated porous titanium foil is anodized in the electrolyte; the composition of the electrolyte: 0.5%-1% HF, 1mol / L H 2 SO 4 , electrolysis potential 20V, electrolysis time 30-120 minutes; after electrolysis, wash with ...

Embodiment 2

[0036] Step (4) electroplating time is 60 minutes, in step (5) 348mg aniline, 202.5mg o-phenylenediamine, 1.5525g 2-acrylamide-2 methylpropanesulfonic acid and 126mg p-acetanilide, 2mol / L HCl dissolved 427.5mg ammonium persulfate, all the other are with embodiment 1.

Embodiment 3

[0038] Step (4) electroplating time is 90 minutes, in step (5) 116.3mg aniline, 67.5mg o-phenylenediamine, 517.5mg2-acrylamide-2 methylpropanesulfonic acid and 42mg p-acetanilide, 2mol / L HCl dissolved 142.5mg ammonium persulfate, all the other are with embodiment 1.

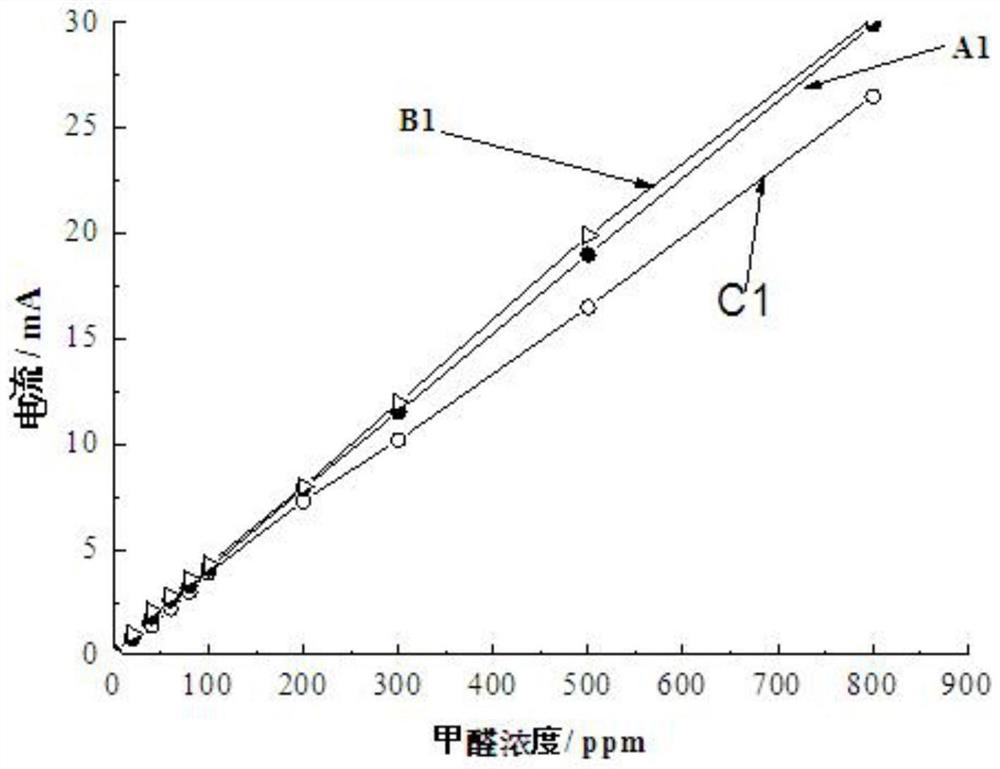

[0039] figure 2 It is the current when the formaldehyde flexible sensor of the sensitive electrode prepared in Example 1, Example 2 and Example 3 is working when the sampling formaldehyde concentration is 0, 20ppm, 40ppm, 60ppm, 80ppm, 100ppm, 200ppm, 300ppm, 500ppm and 800ppm respectively . figure 2 It can be seen that the sensitivity of the three sensors is basically the same, and the zero points are not much different. The formaldehyde concentration can be determined by measuring the current at which the sensor operates while sampling the actual gas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com