Method of modifying platinum base formic acid electrocatalyst

An electrocatalyst, platinum-based formic acid technology, applied in the field of electrochemical catalysis, can solve the problems of difficult realization, unsuitable catalyst production, complex process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

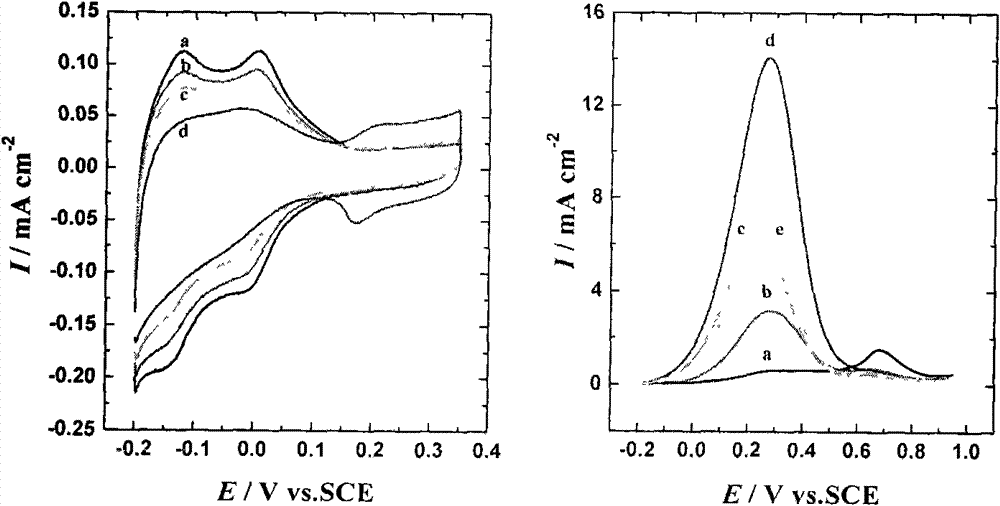

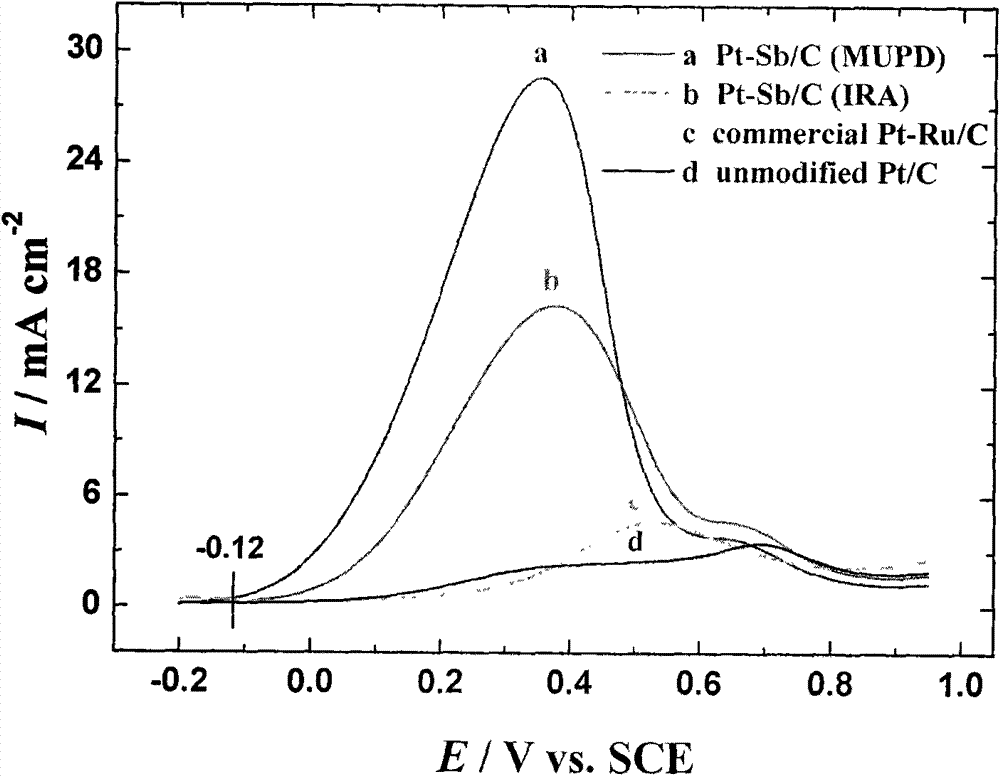

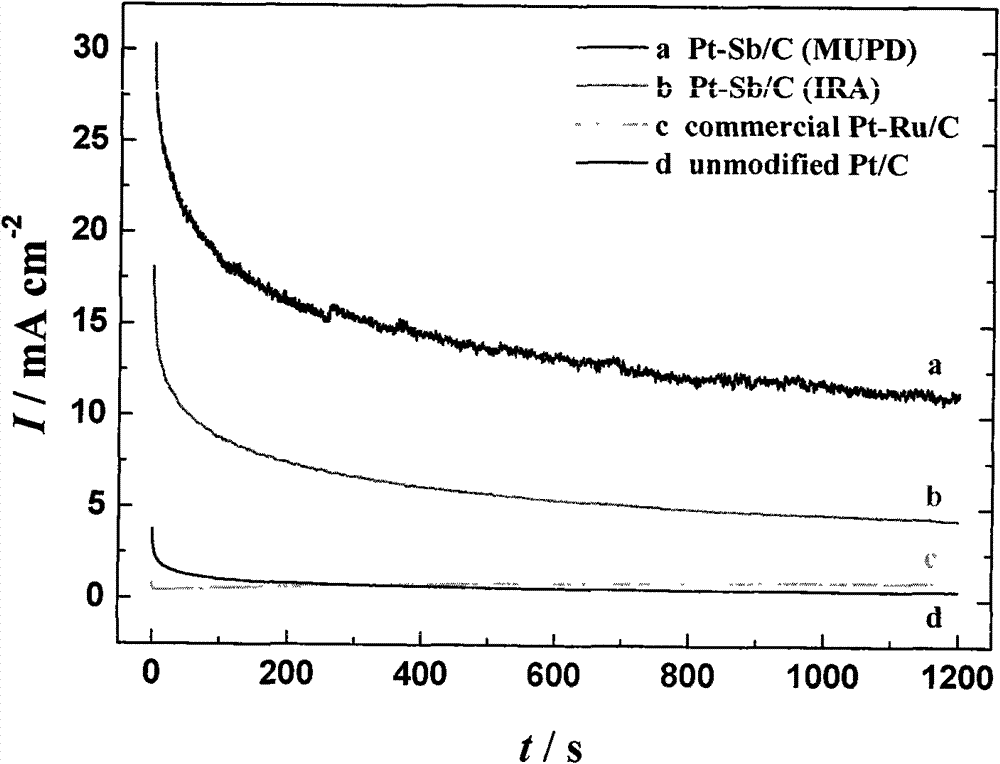

Image

Examples

Embodiment 1

[0020] Weigh a certain amount of Pt / C catalyst (Pt loading is 60%), disperse in ultrapure water for 1 h under ultrasonic conditions, and then mix with 0.1-10×10 -3 mol / L antimony potassium tartrate and 1-20×10 -3 Mix mol / L L-ascorbic acid aqueous solution, continue to ultrasonically disperse for 0.5-10min, filter and wash with ultrapure water several times to remove impurity ions, and dry under vacuum at 50°C to obtain Pt-Sb / C powder.

Embodiment 2

[0022] Weigh a certain amount of Pt / C catalyst (Pt loading is 60%), disperse in ultrapure water for 1 h under ultrasonic conditions, and then mix with 0.1-10×10 -3 mol / L antimony potassium tartrate and 1-20×10 -3 Mix mol / L hydrazine hydrochloride aqueous solution, continue to ultrasonically disperse for 0.5-10min, filter and wash with ultrapure water several times to remove impurity ions, and dry under vacuum at 50°C to obtain Pt-Sb / C powder.

Embodiment 3

[0024] Weigh a certain amount of Pt / C catalyst (Pt loading is 60%), disperse in ultrapure water for 1 h under ultrasonic conditions, and then mix with 0.1-10×10 -3 mol / L antimony trioxide and 1-20×10 -3 Mix mol / L L-ascorbic acid + 0.1-1mol / L sulfuric acid solution, continue ultrasonic dispersion for 0.5-10min, filter and wash with ultrapure water several times to remove impurity ions, and dry under vacuum at 50°C to obtain Pt-Sb / C powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com