A kind of coating method of monolithic catalyst active coating

A monolithic catalyst and active coating technology, applied in catalyst activation/preparation, catalyst carrier, chemical instruments and methods, etc., can solve the problem of uneven coating, difficult to control slurry viscosity and fluidity, low coating rate, etc. problem, to achieve the effect of uniform coating, no sintering, and high loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

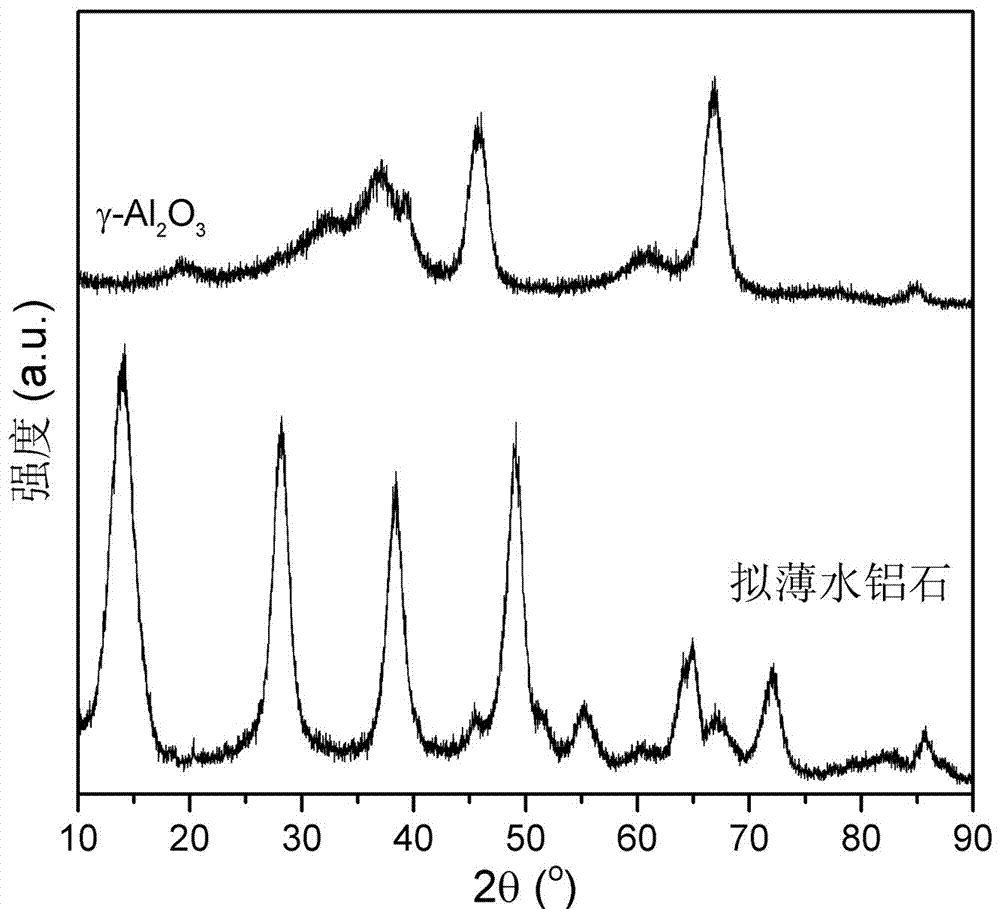

[0023] First, weigh 200 g of deionized water and place it in a 500 mL beaker, and add 190 g of γ-Al 2 o 3 and 10 g of pseudo-boehmite, add concentrated nitric acid (65% by mass fraction) to adjust the pH value of the slurry to 3.9, and continue stirring for 15 minutes.

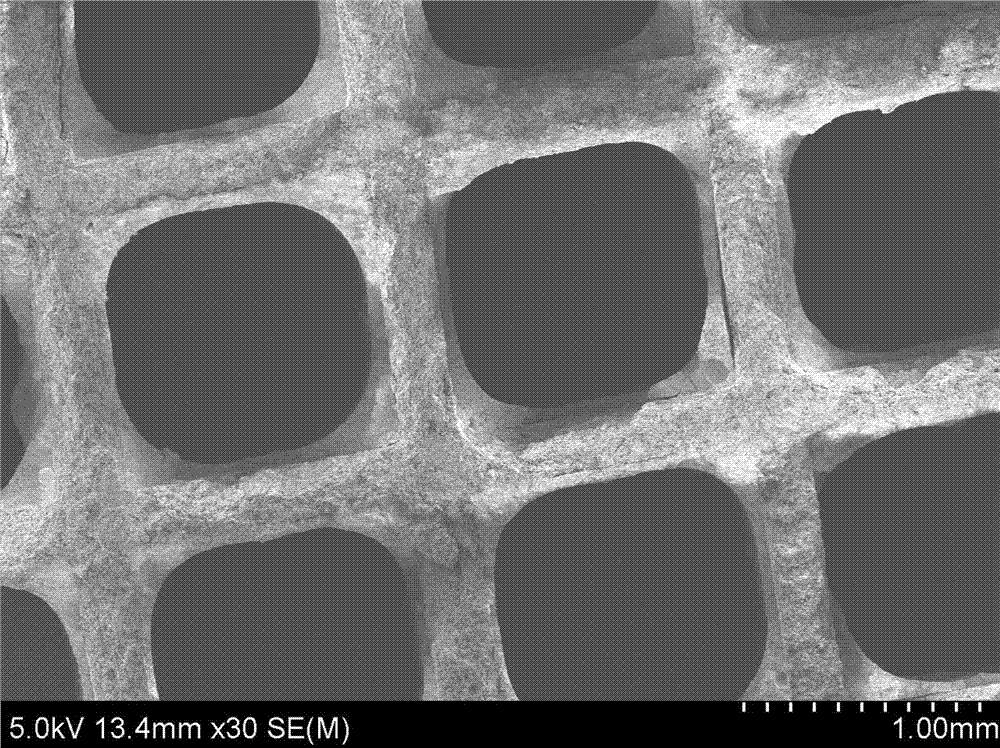

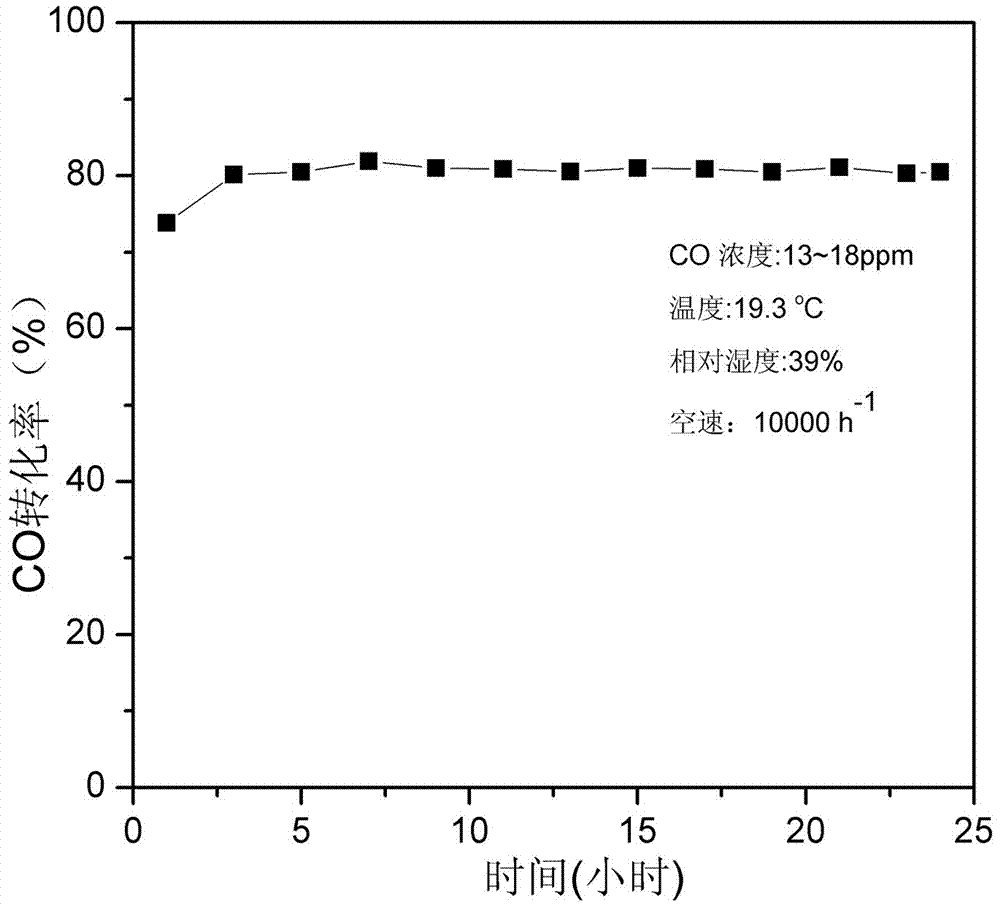

[0024] Measure 200 mL of slurry in an evaporating dish with an inner diameter of 7 cm, put half of the cordierite carrier with a specification of 5 cm*5 cm*5 cm in the above evaporating dish, soak for 5-10 s, take it out, and use an empty The press blows the slurry at the mouth of the channel into the channel, and blows out the excess slurry. After all the channels no longer have excess slurry, the other half of the carrier that is not impregnated with slurry is submerged in the slurry again , soak for 5-10 s, take it out, blow the slurry into the channel with an air compressor, blow out the excess slurry, and dry it at room temperature for a few minutes. Transfer to an oven at 50°C for 12 h, and then bake i...

Embodiment 2

[0026] First, weigh 200 g of deionized water and place it in a 500 mL beaker, and add 185 g of γ-Al 2 o 3 and 15 g of pseudo-boehmite, adding concentrated nitric acid (65% by mass fraction) to adjust the pH value of the slurry to 3.9, and continued to stir for 15 minutes.

[0027] Measure 200 mL of slurry in an evaporating dish with an inner diameter of 7 cm, put half of the cordierite carrier with a specification of 5 cm*5 cm*5 cm in the above evaporating dish, soak for 5-10 s, take it out, and use an empty The press blows the slurry at the mouth of the channel into the channel, and blows out the excess slurry. After all the channels no longer have excess slurry, the other half of the carrier that is not impregnated with slurry is submerged in the slurry again , soak for 5-10 s, take it out, blow the slurry into the channel with an air compressor, blow out the excess slurry, and dry it at room temperature for a few minutes. Transfer to an oven at 50°C for 12 h, and then bak...

Embodiment 3

[0029] First, weigh 200 g of deionized water and place it in a 500 mL beaker, and add 175 g of γ-Al 2 o 3 and 25 g of pseudo-boehmite, adding concentrated nitric acid (65% by mass fraction) to adjust the pH value of the slurry to 3.9, and continued to stir for 15 minutes.

[0030]Measure 200 mL of slurry in an evaporating dish with an inner diameter of 7 cm, put half of the cordierite carrier with a specification of 5 cm*5 cm*5 cm in the above evaporating dish, soak for 5-10 s, take it out, and use an empty The press blows the slurry at the mouth of the channel into the channel, and blows out the excess slurry. After all the channels no longer have excess slurry, the other half of the carrier that is not impregnated with slurry is submerged in the slurry again , soak for 5-10 s, take it out, blow the slurry into the channel with an air compressor, blow out the excess slurry, and dry it at room temperature for a few minutes. Transfer to an oven at 50°C for 12 h, and then bake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com