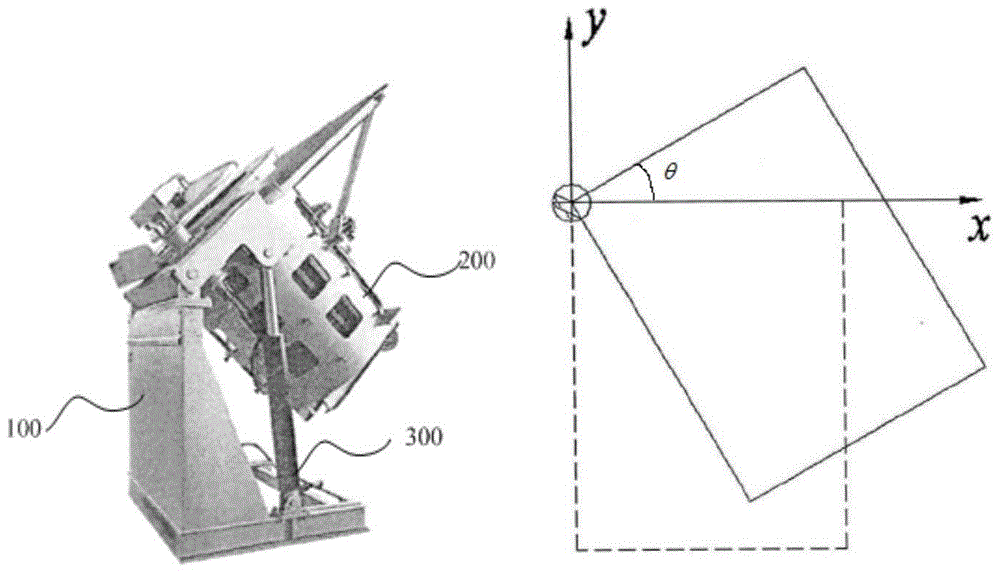

Quantitative casting control method and system for tilting casting machine

A control method and technology of a control system, which are applied in the field of quantitative casting control of a tilting casting machine, can solve the problems of low control accuracy and difficulty in establishing a tracking model, and achieve the goal of avoiding mathematical modeling and fluid mechanics analysis process and simplifying the burden. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] An embodiment of the present invention provides a quantitative casting control method for a tilting casting machine, including:

[0050] S100, calculating the pouring weight of the melt poured into the ladle by the electric furnace;

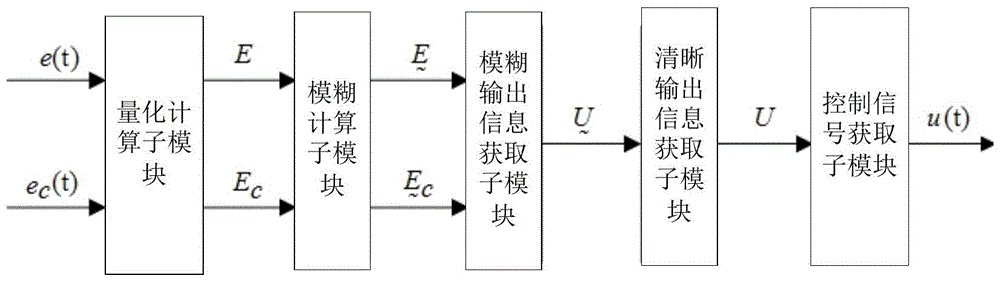

[0051] S200. Obtain a casting weight deviation according to the casting weight and the set casting weight, and calculate the rate of change of the casting weight deviation;

[0052] S300. Search a fuzzy control table according to the casting weight deviation and the rate of change of the casting weight deviation to obtain a control signal.

[0053] The display control method provided by the present invention will be described in detail below.

[0054] First, S100 is introduced, the step of calculating the pouring weight of the melt poured into the ladle by the electric furnace.

[0055] In the embodiment of the present invention, the calculation of casting weight includes two situations. in,

[0056] The first case is the inner loop fe...

Embodiment 2

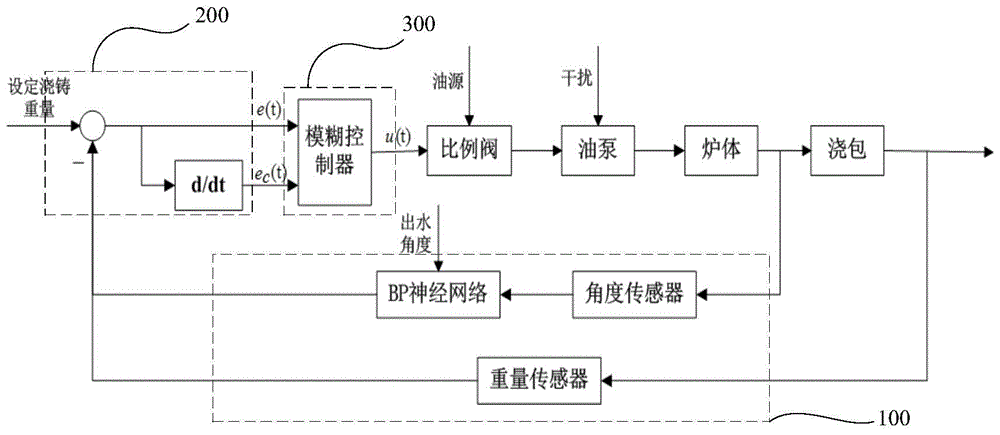

[0101] In order to further embody the superiority of the quantitative casting control method for the tilting casting machine provided by the embodiment of the present invention, the automatic casting control system with 120 metal grinding balls will be described in detail below.

[0102] Such as figure 2 As shown, according to the process requirements, the 120 metal grinding ball casting system needs to cast 35kg per package, the deviation is within ±0.5kg, and the casting time should not exceed 40 seconds.

[0103] According to the control method described above, the casting weight deviation, the rate of change of the casting weight deviation and the value range of the control signal u are firstly determined.

[0104]When the casting has not yet started, the casting weight deviation is just the lower limit -35kg. Since the casting weight deviation is required to be within ±0.5kg, the upper limit of the casting weight deviation e should be +0.5kg in theory, but in some cases ...

Embodiment 3

[0141] Further reflecting the superiority of the quantitative casting control method for the tilting casting machine provided by the embodiment of the present invention, the embodiment of the present invention also provides a quantitative casting control system for the tilting casting machine, such as figure 2 shown, including:

[0142] Calculation module 100, used for calculating the pouring weight of the melt poured into the ladle by the electric furnace;

[0143] The comparison module 200 is used to obtain the casting weight deviation according to the casting weight and the set casting weight, and calculate the rate of change of the casting weight deviation;

[0144] The fuzzy controller 300 is used to search the fuzzy control table to obtain the control signal according to the casting weight deviation and the rate of change of the casting weight deviation.

[0145] Understandably, figure 2 Proportional valve, oil pump, furnace body, ladle, etc. are commonly used device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com