An automatic loading and unloading manipulator for a numerically controlled lathe

A technology of automatic loading and unloading and CNC lathe, which is applied in the direction of manipulators, metal processing, manufacturing tools, etc., can solve the problems of high cost, danger, and time-consuming, and achieve the effect of automatic control, high safety factor, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

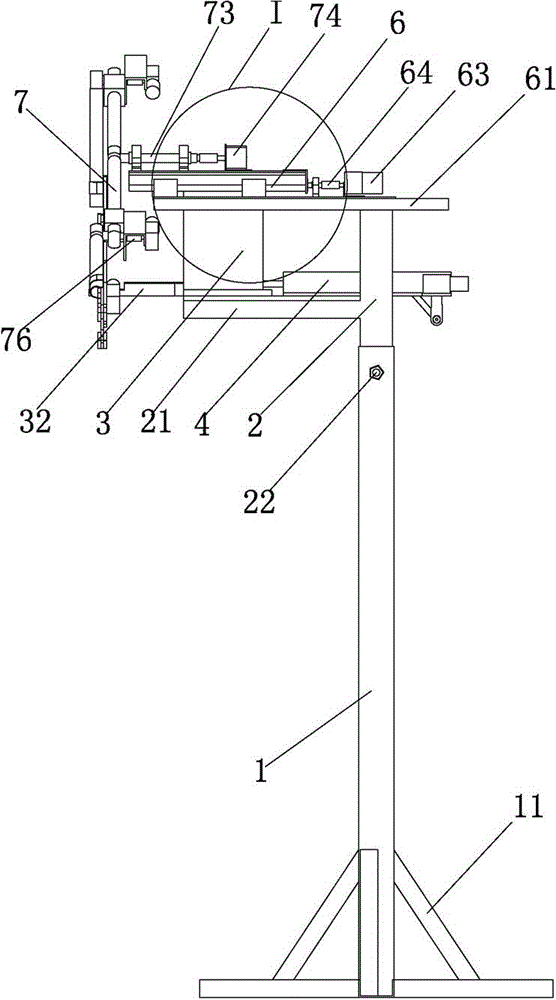

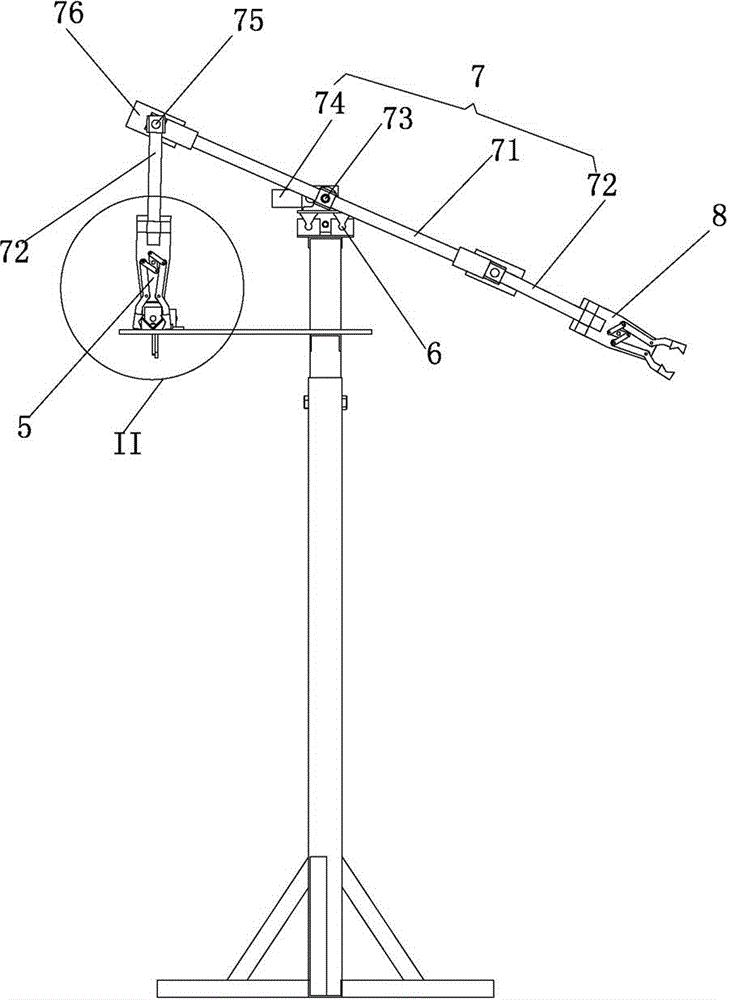

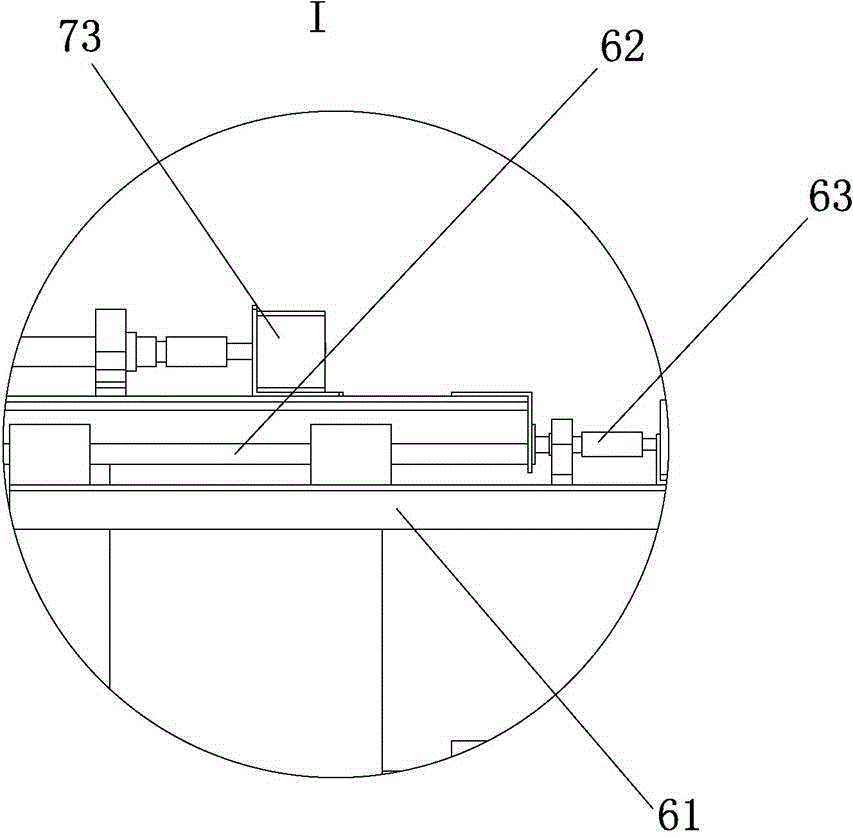

[0034] Please refer to the attached figure 1 To attach Figure 9 As shown, the present invention is an automatic loading and unloading manipulator of a numerical control lathe, which consists of a base 1, a support 2, a raw material box 3, a push rod mechanism 4, a first mechanical claw 5, a slide rail mechanism 6, a mechanical arm 7 and a second Several parts such as mechanical claw 8 are formed.

[0035] Wherein, the bracket 2 is installed on the base 1, and a supporting plate 21 is arranged on it. Specifically, the bracket 2 is installed on the base 1 through a screw rod 22 , the height of the bracket 2 can be adjusted by loosening the screw rod 22 , and the bracket 2 and the base 1 can be fixedly connected by tightening the screw rod 22 . The base 1 is welded with several obliquely arranged reinforcing ribs 11 , so that the structural strength of the base 1 can be increased.

[0036] The raw material box 3 and the push rod mechanism 4 are installed on the supporting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com