Method for using gray-tone exposure to generate miniature picture in micro-nano size

A micro-nano and dimensional technology, applied in the field of electron beam lithography, can solve the problems of no obvious advantages in the field of micro-nano structure and the inability to realize irregular pattern preparation, etc., and achieve the effect of high-efficiency nano-pattern manufacturing and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further specifically described below in conjunction with the accompanying drawings and embodiments.

[0020] Concrete operation steps of the present invention are as follows:

[0021] (1) Use Beamer software to form exposure files;

[0022] (2) Clean the silicon substrate, spin-coat PMMA glue with a thickness of 2.5 microns on the substrate, and bake it to harden. The baking temperature is 180 degrees Celsius and the time is 60 minutes. See figure 1 ;

[0023] (3) Use an electron beam lithography machine to expose the designed pattern, see figure 2 ;

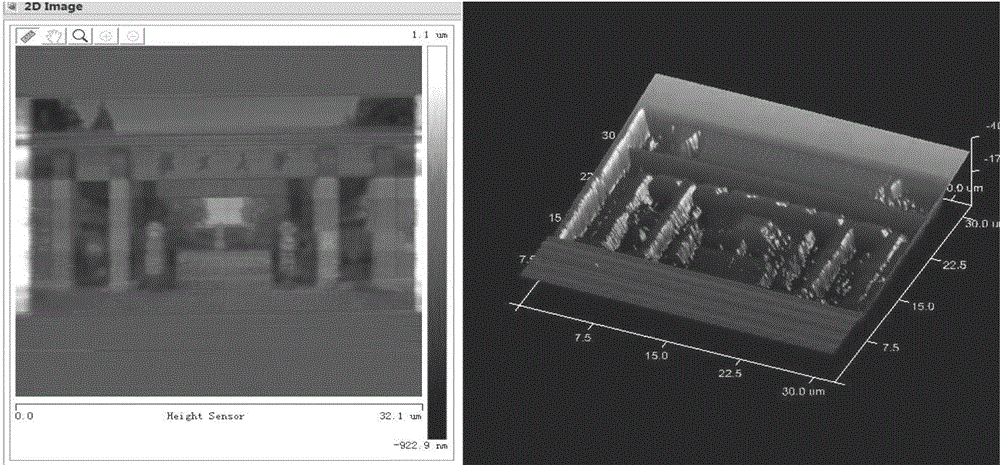

[0024] (4) Develop in 1:1 MIBK and IPA solution at 23 degrees Celsius for 1 minute, then immediately rinse in IPA solution for 30 seconds. Photoresists with different thicknesses have different black and white grayscales after development, thereby generating micro-nano-sized 3D microphotographs, see image 3 , are the AFM top view and oblique view of the finished sample, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com