A treatment method for oil refinery waste lye containing organic nitrogen

A technology for oil refining waste lye and treatment methods, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems that have not been used as inspection indicators, and improve oil removal efficiency , good treatment effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

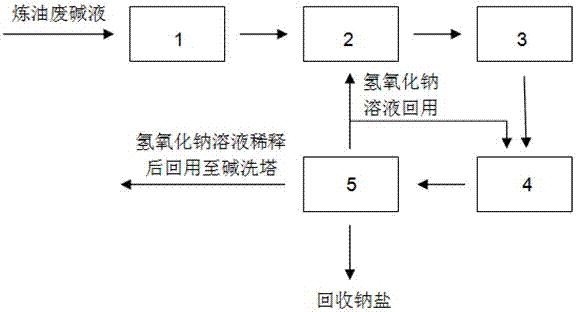

Image

Examples

Embodiment 1

[0030] A stream of waste lye from oil refinery containing organic nitrogen, its COD is 358000mg / L, the concentration of organic nitrogen is 10670mg / L, S 2- The concentration is 46900mg / L, the concentration of phenol is 89000mg / L, the concentration of sodium carbonate is 19800mg / L, the concentration of sodium hydroxide is 3wt%, and the concentration of oil is 190mg / L. Adopt the inventive method to process under the following conditions:

[0031] (1) Air flotation degreasing: Air is introduced into the waste lye to generate air bubbles in the waste lye, and a small amount of light oil entrained in the waste lye sticks to the air bubbles, and is removed by floating on the water surface with the gas. After the air flotation and oil removal treatment, the oil content in the waste caustic liquor was reduced to 13mg / L.

[0032] (2) High-temperature wet oxidation treatment: the reaction temperature of the treatment is 270°C, the reaction pressure is 9.0MPa, and the reaction time is 4...

Embodiment 2

[0037] A stream of waste lye from oil refinery containing organic nitrogen, its COD is 463500mg / L, organic nitrogen concentration is 11980mg / L, S 2- The concentration is 68000mg / l, the concentration of phenol is 113600mg / L, the concentration of sodium carbonate is 21300mg / L, the concentration of sodium hydroxide is 2.6wt%, and the concentration of oil is 230mg / L. Adopt the inventive method to process under the following conditions:

[0038] (1) Air flotation degreasing: Air is introduced into the waste lye to generate air bubbles in the waste lye, and a small amount of light oil entrained in the waste lye sticks to the air bubbles, and is removed by floating on the water surface with the gas. After air flotation and deoiling treatment, the oil content in the waste caustic liquor is reduced to 15mg / L.

[0039] (2) High-temperature wet oxidation treatment: the reaction temperature of the treatment is 290°C, the reaction pressure is 12.0MPa, and the reaction time is 60min. Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com