An ultra-deep sea offshore oil and gas dry production system and its installation and evacuation method

A production system, dry technology, applied in earth-moving drilling, production of fluids, wellbore/well components, etc., can solve the problems of high hydrostatic pressure, numerous instruments, and high design requirements in underwater wellhead tanks, reducing wave force and Stream load forces, reduced installation risks and costs, the effect of a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

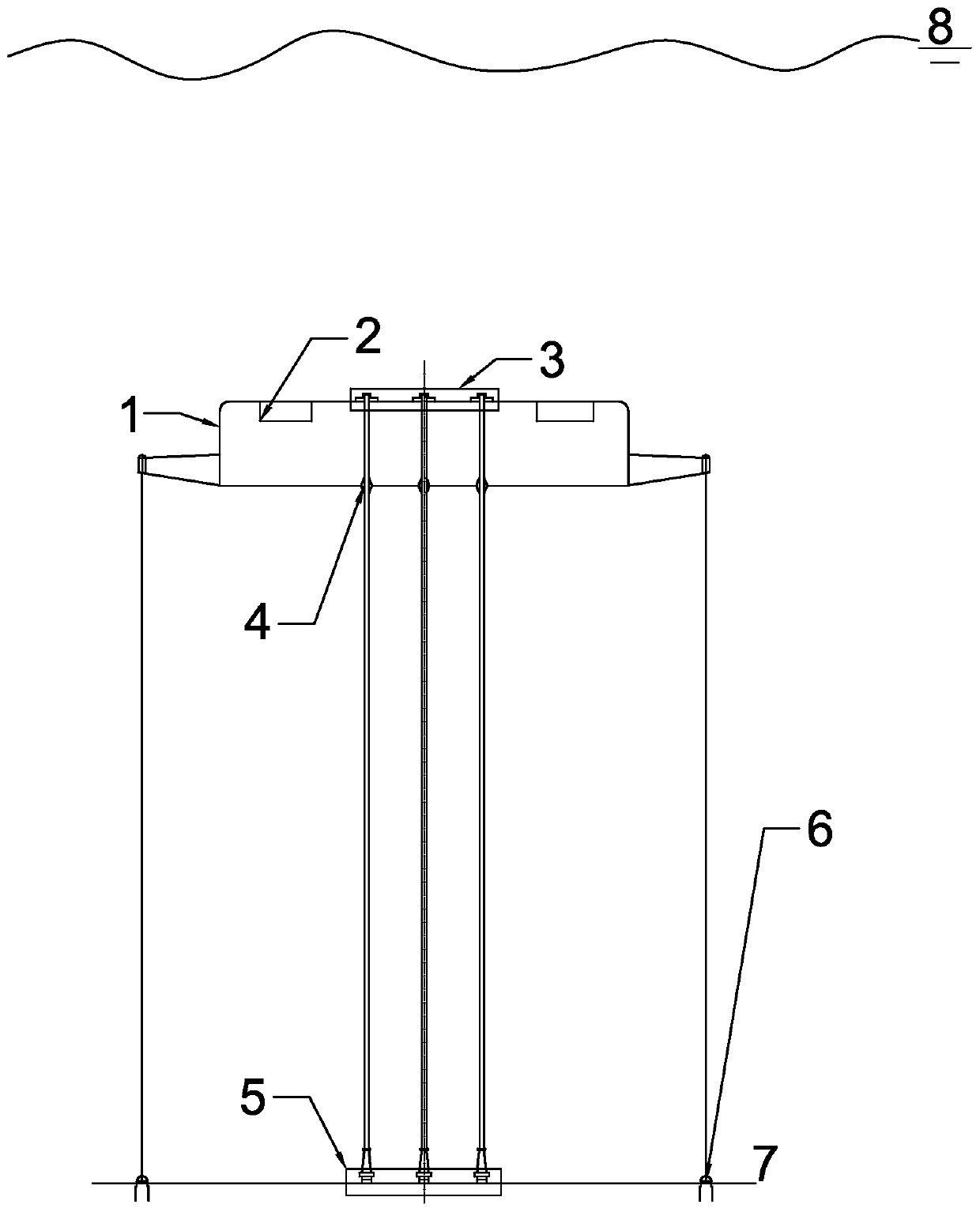

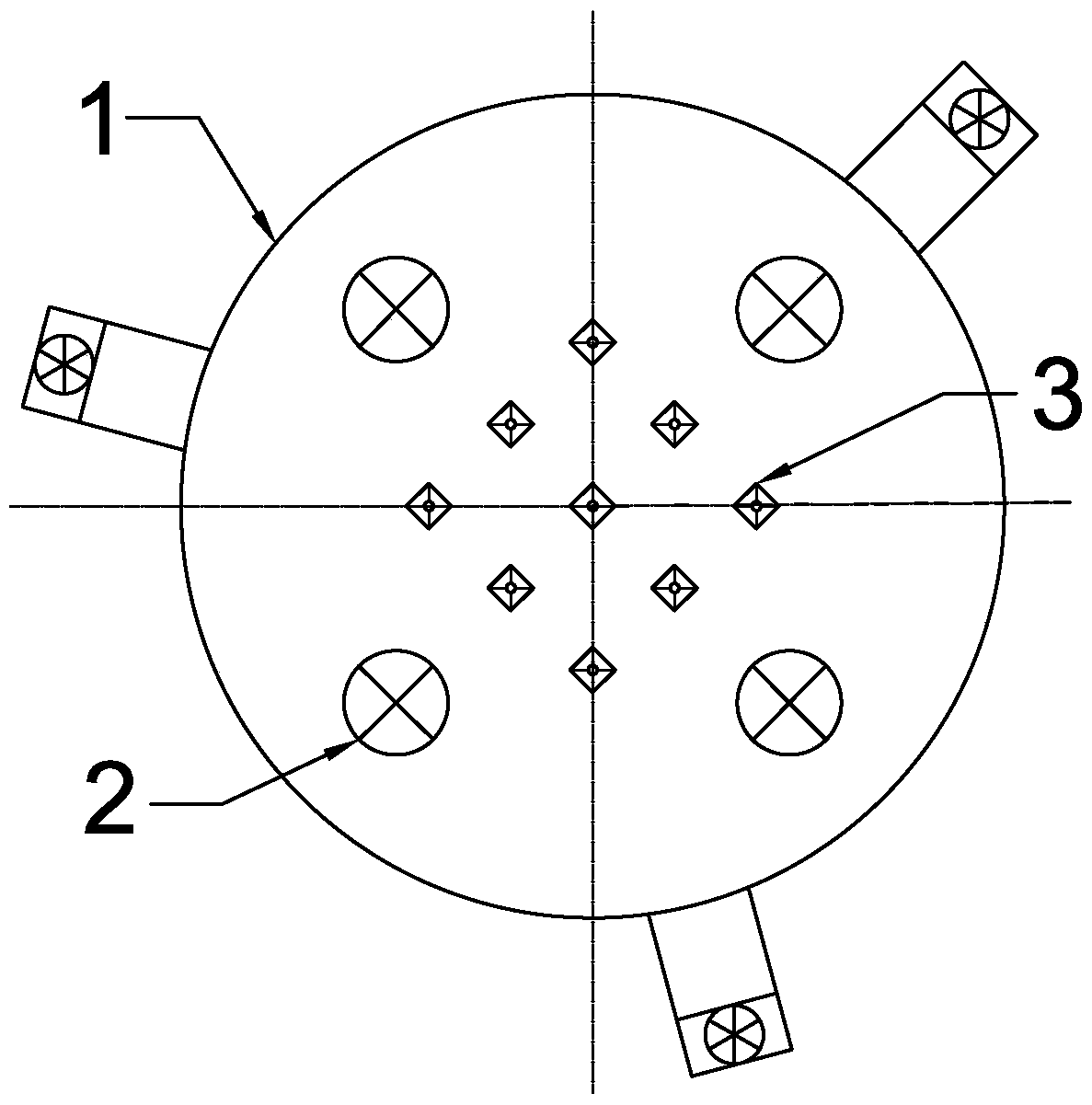

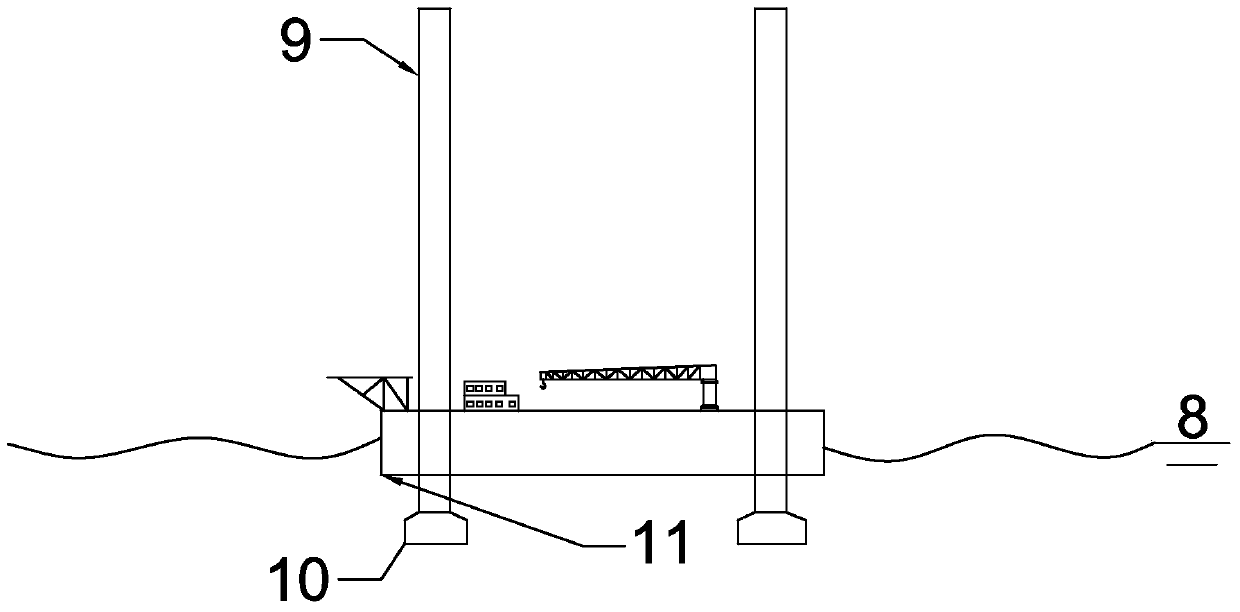

[0059] Such as Figure 1-11 As shown, an ultra-deep sea offshore oil and gas dry production system includes a mobile oil production platform, dry production equipment, an underwater platform 1 , a rigid riser system, a tension mooring system 6 and an underwater wellhead system 3 .

[0060] The rigid riser system includes a lower rigid riser system 4 and an upper rigid riser system 12 . The lower rigid riser system 4 connects the oil and gas production channel back from the subsea wellhead system 5 to the underwater wellhead system 3, and the upper rigid riser system 12 connects the oil and gas production channel back from the underwater wellhead system 3 to the dry wellhead system of the mobile oil production platform .

[0061] The mobile oil production platform is used to support the dry production equipment and the upper rigid riser system 12, and is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com